Two-dimensional ZnS/ZnO/ZnS nanosheet photocatalyst and preparation method thereof

A technology of photocatalysts and nanosheets, applied in the direction of physical/chemical process catalysts, chemical instruments and methods, chemical/physical processes, etc., to achieve the effects of good repeatability, controllable thickness, and increased light absorption area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

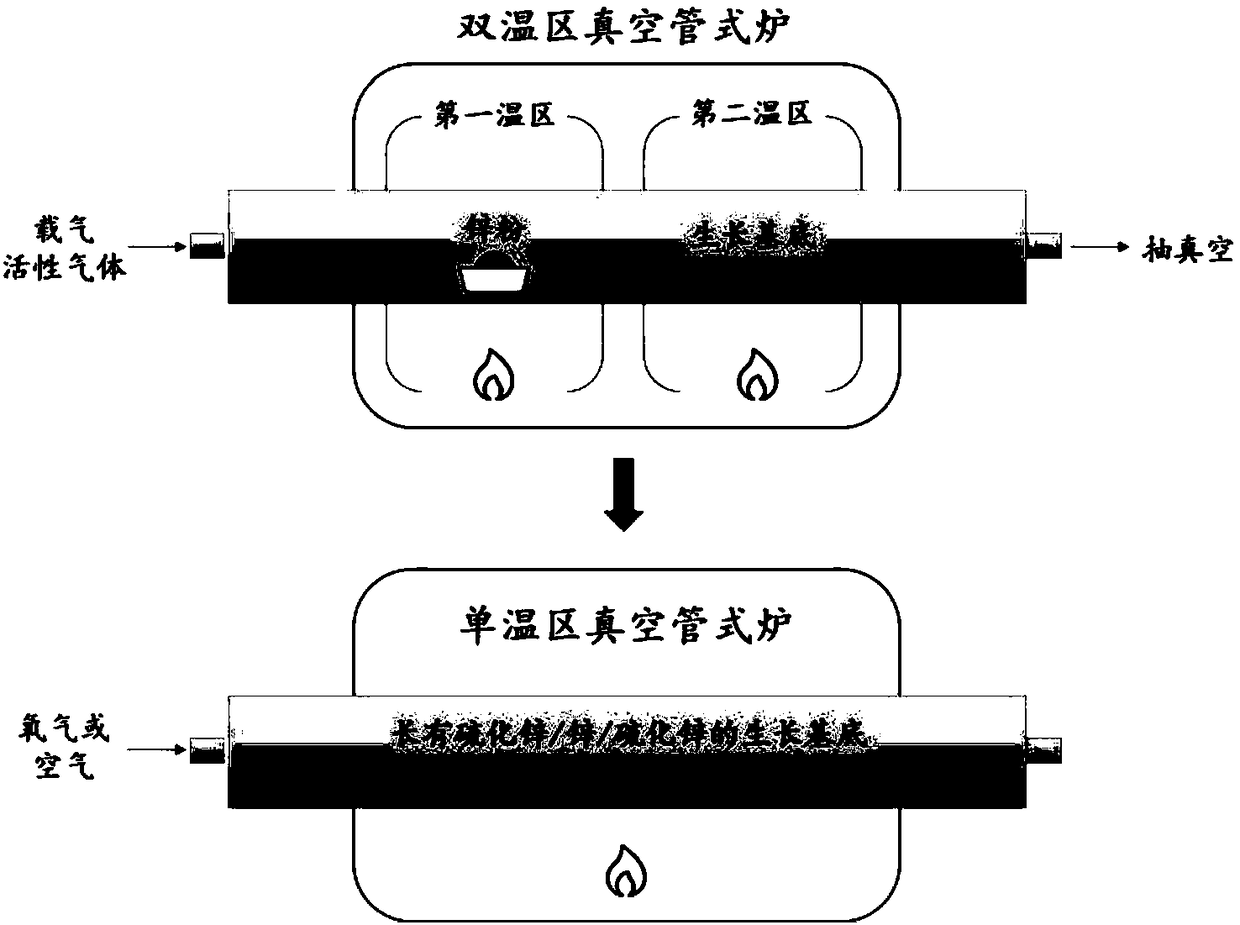

Embodiment 1

[0030] A method for preparing ultra-thin two-dimensional ZnS / ZnO / ZnS sandwich structure nanosheet material by vapor phase synthesis. The specific method steps are as follows: use a balance to weigh 1g of Zn powder as a raw material in a small porcelain boat, and place it in a double-temperature zone vacuum tube furnace. In the first temperature zone, the FTO glass (fluorine-doped SnO 2 Conductive glass) is placed in the second temperature zone as the growth substrate, and then the vacuum tube furnace with dual temperature zones is evacuated to 0.1 Torr; nitrogen gas is introduced, the gas flow rate is controlled to 400 sccm, and the time is 10s, and then the carrier gas is closed and vacuumized to 0.2Torr, repeat this step 3 times; feed N into the double temperature zone vacuum tube furnace 2 and CS 2 , control N2 Flow rate is 40sccm, CS 2 The flow rate is 10sccm, and the pressure of the double-temperature zone vacuum tube furnace is adjusted to 2Torr; the temperature of the...

Embodiment 2

[0036] A method for preparing ultra-thin two-dimensional ZnS / ZnO / ZnS sandwich structure nanosheet material by vapor phase synthesis. The specific method steps are as follows: use a balance to weigh 2g of Zn powder as a raw material in a small porcelain boat, and place it in a double-temperature zone vacuum tube furnace. In the first temperature zone, the FTO glass (fluorine-doped SnO 2 Conductive glass) is placed in the second temperature zone as the growth substrate, and then the vacuum tube furnace with dual temperature zones is evacuated to 0.1 Torr; nitrogen gas is introduced, the gas flow rate is controlled to 400 sccm, and the time is 10s, and then the carrier gas is closed and vacuumized to 0.2Torr, repeat this step 3 times; feed N into the double temperature zone vacuum tube furnace 2 and SO 2 , control N 2 The flow rate is 40sccm, SO 2 The flow rate is 5 sccm, and the pressure of the dual-temperature zone vacuum tube furnace is adjusted to 1.8 Torr; the temperature...

Embodiment 3

[0039] A method for preparing ultra-thin two-dimensional ZnS / ZnO / ZnS sandwich structure nanosheet material by vapor phase synthesis. The specific method steps are as follows: Use a balance to weigh 3g of Zn powder as a raw material in a small porcelain boat, and place it in a vacuum tube furnace with two temperature zones. In the first temperature zone, the FTO glass (fluorine-doped SnO 2 Conductive glass) is placed in the second temperature zone as the growth substrate, and then the vacuum tube furnace with dual temperature zones is evacuated to 0.3 Torr; nitrogen gas is introduced, the gas flow rate is controlled to 400 sccm, and the time is 10s; finally, the carrier gas is turned off and the vacuum is evacuated to 0.2Torr; repeat this step 3 times; feed N into the double temperature zone vacuum tube furnace 2 and SO 2 , control N 2 The flow rate is 50sccm, SO 2 The flow rate is 20sccm, and the pressure of the dual-temperature zone vacuum tube furnace is adjusted to 2.5To...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com