Flexible gallium arsenide solar cell and manufacturing method thereof

A solar cell and gallium arsenide technology, applied in circuits, photovoltaic power generation, electrical components, etc., can solve the problems of low yield, low specific power, and poor flexibility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

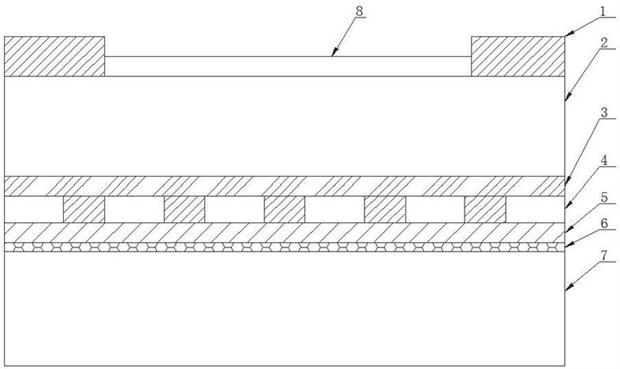

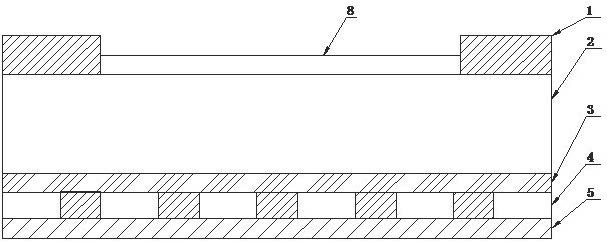

[0038] See Figure 1-Figure 2 , A flexible gallium arsenide solar cell, including a bottom electrode 5 vapor-deposited on the bottom of a patterned PI substrate 4, a bonding metal 3 vaporized on the top of the patterned PI substrate 4, and the bonding metal 3 combines the PI film and the epitaxial layer 2 Bonding, the epitaxial layer 2 is a single-junction gallium arsenide solar cell or a multi-junction gallium arsenide solar cell grown upside down. Above the epitaxial layer 2 are the upper electrode 1 and the anti-reflection film 8. The upper electrode 1 is a rectangular strip , And arranged adjacent to the anti-reflection film 8.

[0039] The preparation method includes the following:

[0040] First, grow a gallium arsenide buffer layer, a GaInP or AlInP corrosion stop layer, a single-junction or multi-junction gallium arsenide solar cell, and a highly doped P-type contact layer on the gallium arsenide substrate in sequence;

[0041] Then, a metal contact layer and a bonding laye...

Embodiment 2

[0052] Such as Figure 4 Shown: The corroded shape is composed of n equal rectangular vertical bars (for example, 9 same rectangular vertical bars) and n-1 rectangular horizontal bars, and the middle of the long sides of the n same rectangular vertical bars pass through n-1 The rectangular horizontal bars are connected, and the short side length of the rectangular vertical bars is equal to the short side length of the rectangular horizontal bars, so that the patterned PI substrate 4 has the advantages of light weight, high thermal conductivity, and easy attachment. The rest is the same as in Embodiment 1.

Embodiment 3

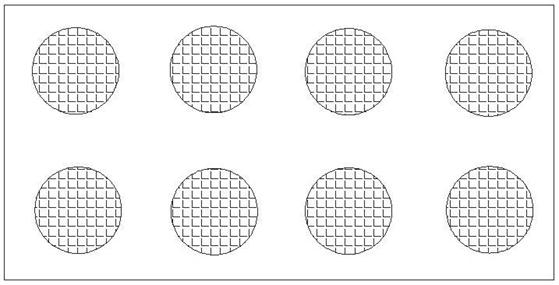

[0054] Such as Figure 5 And as Image 6 As shown, the corroded shape can also be an irregular shape, such as an irregular arc or polygon, so that the patterned PI substrate 4 has the advantages of light weight, high thermal conductivity, and easy attachment. The rest is the same as in Embodiment 1.

[0055] The solar cell prepared in Example 1 was tested, and its specific parameters are shown in Table 2.

[0056] Table 2: Comparison table of photoelectric performance of flexible battery

[0057]

[0058] According to Table 2, the fill factor and conversion efficiency of the flexible battery produced by the patented process are improved, and the overall performance of the battery is better than that of the conventional process.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com