Heterogeneous junction solar cell edge insulating method

A solar cell and edge insulation technology, applied in the field of solar cells, can solve problems such as winding and plating, and achieve the effect of increasing light absorption area, improving production efficiency and conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

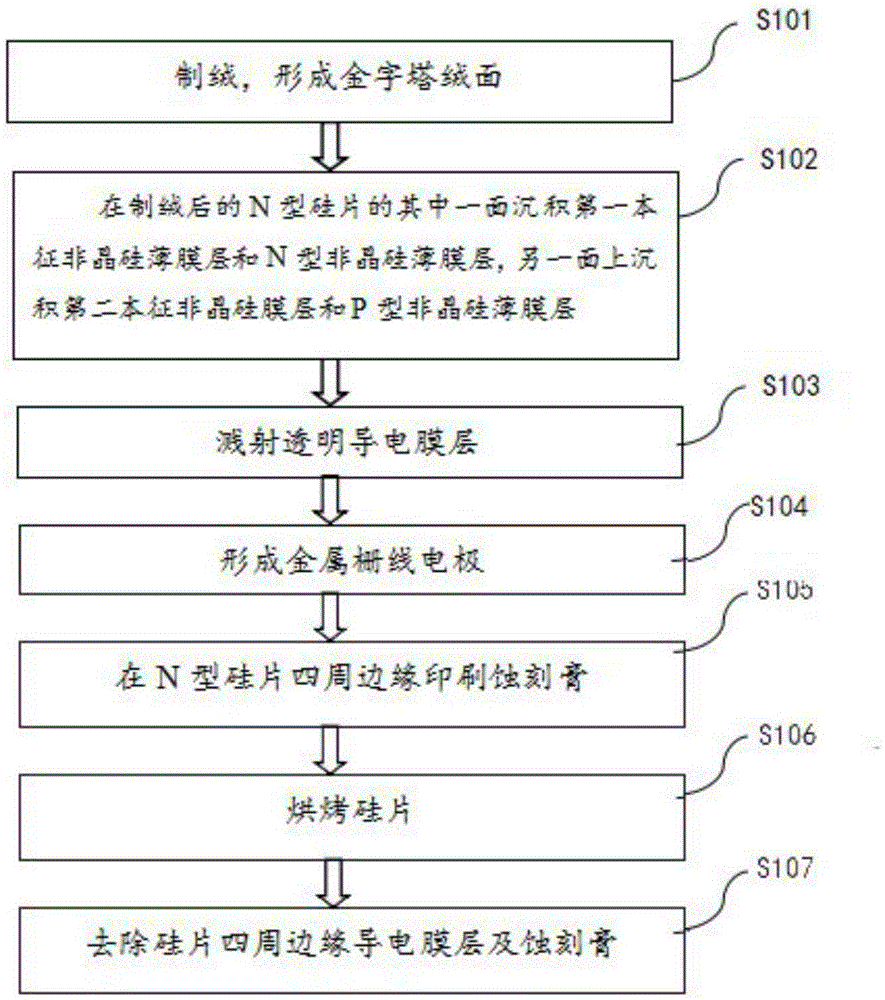

[0023] like Figure 1-3 As shown, the invention discloses a heterojunction solar cell edge insulation method, which includes the following steps:

[0024] S101 Texture cleaning on both sides of the N-type silicon wafer 1 to form a pyramid texture;

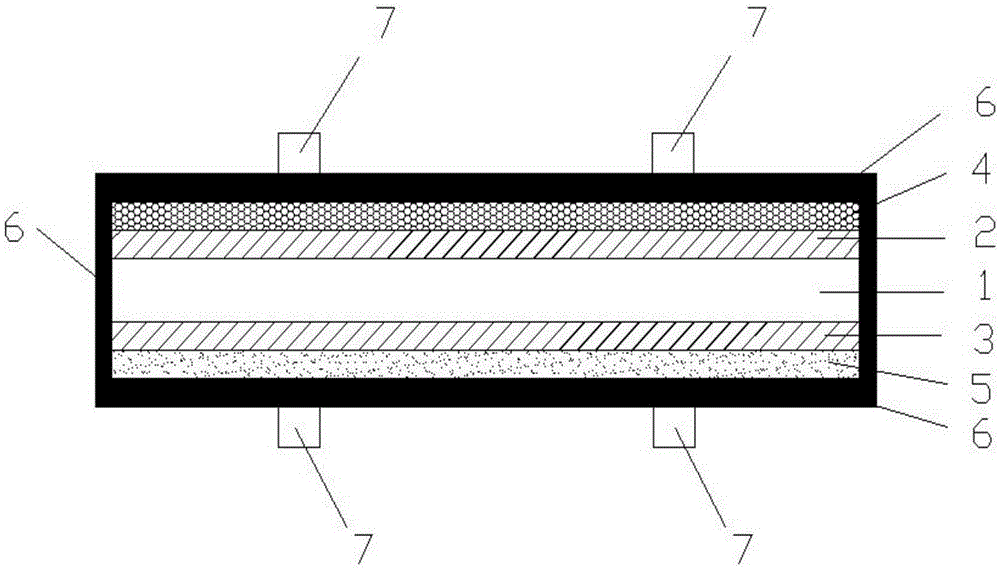

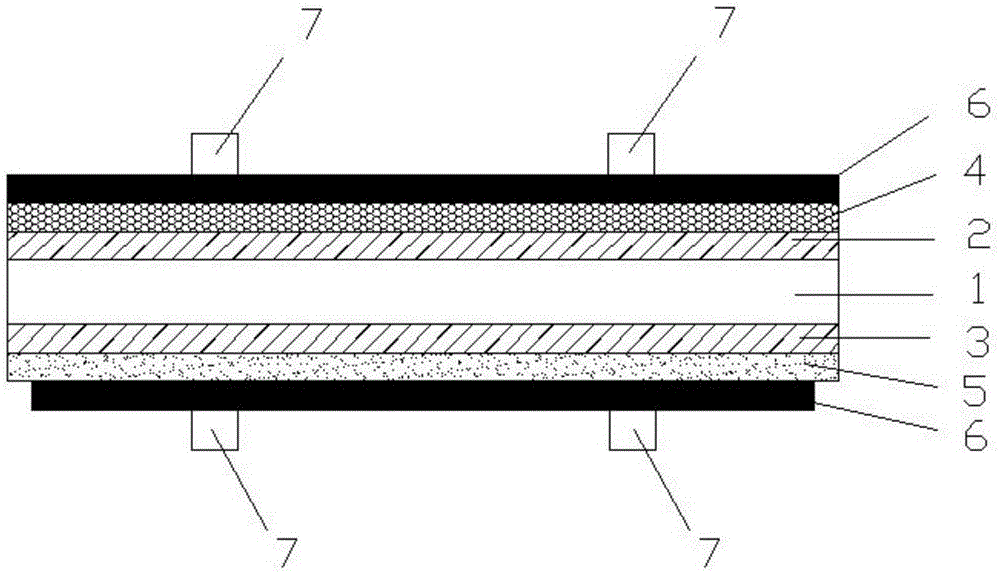

[0025] S102 Deposit the first intrinsic layer 2 and the N-type amorphous silicon film layer 4 on one side of the N-type silicon wafer 1 after texturing, and deposit the second intrinsic amorphous silicon film layer 3 and the P-type amorphous silicon film layer 4 on the other side. Silicon film layer 5;

[0026] S103 sputtering the conductive film layer 6 on both sides of the N-type silicon wafer 1;

[0027] S104 forming a metal grid line electrode 7 on the conductive film layer 6 on both sides of the N-type silicon wafer;

[0028] S105 prints etching paste on the surrounding edges of the backlight surface P side or the light receiving surface N surface of the N-type silicon wafer; in an embodiment, the etching paste can be print...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com