A method for slicing heterojunction shingled solar cells

A solar cell and heterojunction technology, applied in circuits, photovoltaic power generation, electrical components, etc., can solve the problems affecting the efficiency and stability of shingled components, affecting the performance of solar cells, and destroying the amorphous silicon layer, and achieving the benefits of large Large-scale automated production, improved performance and reliability, and the effect of avoiding increased leakage current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

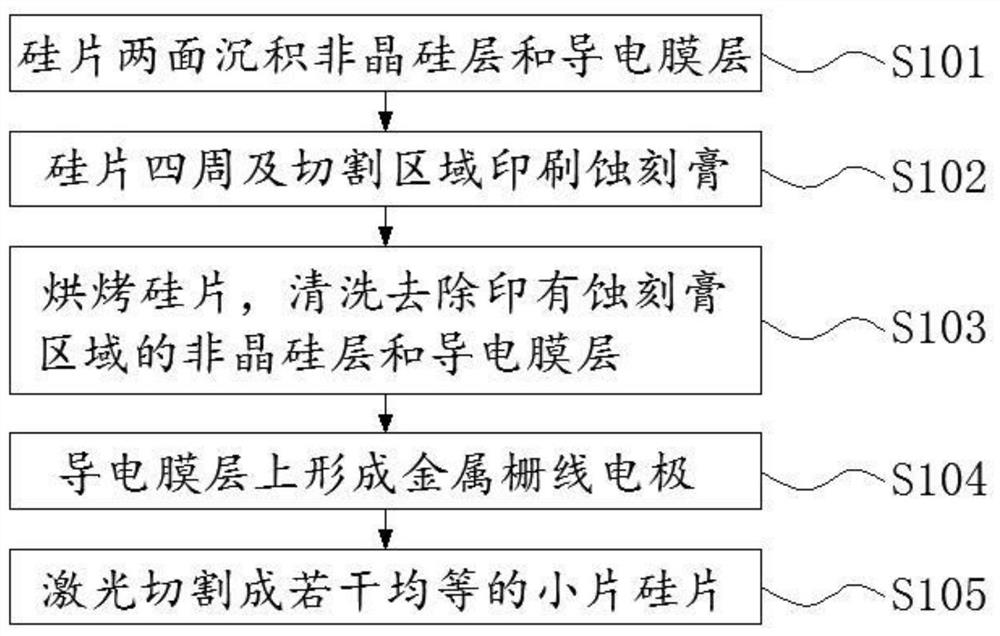

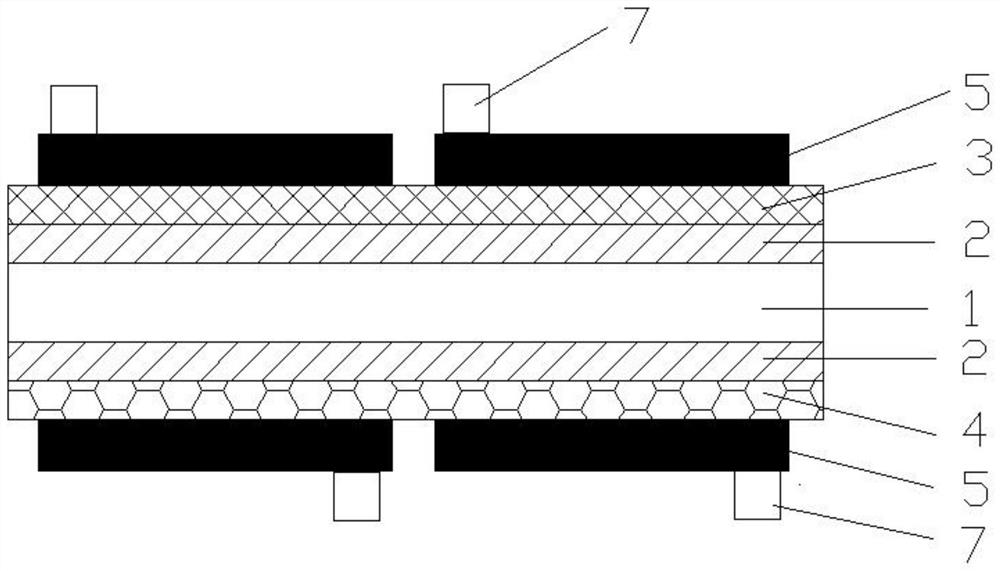

[0026] refer to Figure 1 ~ Figure 3 As shown, the present invention is a method for slicing heterojunction shingled solar cells, the method comprising the following steps:

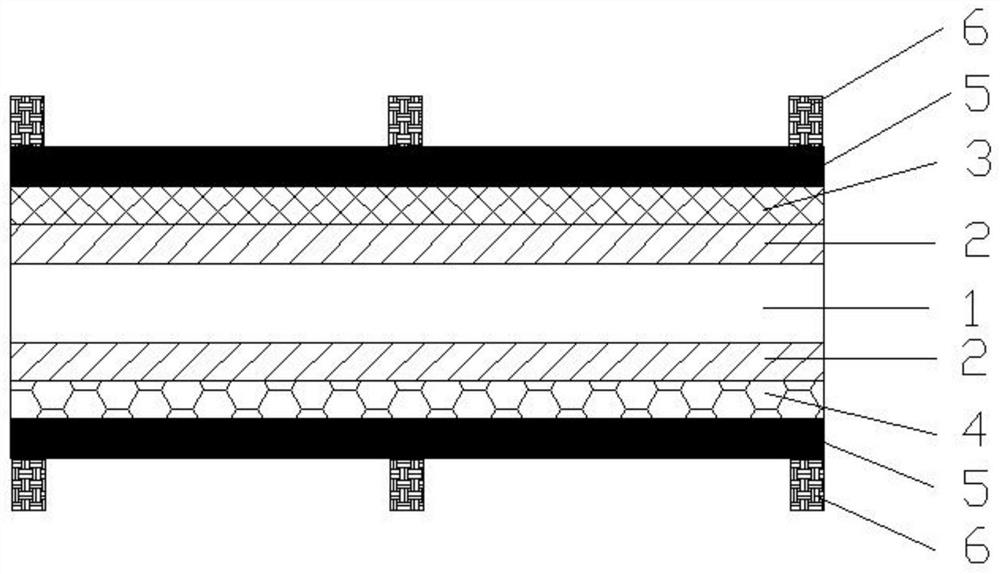

[0027] Step S101, depositing a thin intrinsic amorphous silicon layer 2 and an n-type amorphous silicon layer 3 on one side of the n-type silicon wafer substrate 1 with a textured surface after cleaning, and depositing a thin intrinsic amorphous silicon layer 2 and a p-type amorphous silicon layer on the other side amorphous silicon layer 4, and deposit a conductive film layer 5 on the n-type amorphous silicon layer 3 and the p-type amorphous silicon layer 4, the conductive film layer is deposited by magnetron sputtering, and the conductive film layer is transparent and conductive An oxide film layer or a composite film layer of a transparent conductive oxide film layer and a metal film layer, the transparent conductive oxide film layer includes ITO, AZO, IGZO and doped indium oxide, and the metal film la...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com