Preparation method of solar cell

A solar cell and seed layer technology, applied in circuits, photovoltaic power generation, electrical components, etc., can solve the problems of increasing the production cost of cells, complicating the production process, affecting the performance of components, etc., which is conducive to large-scale automated production, reducing Mechanical damage, beneficial effect on yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

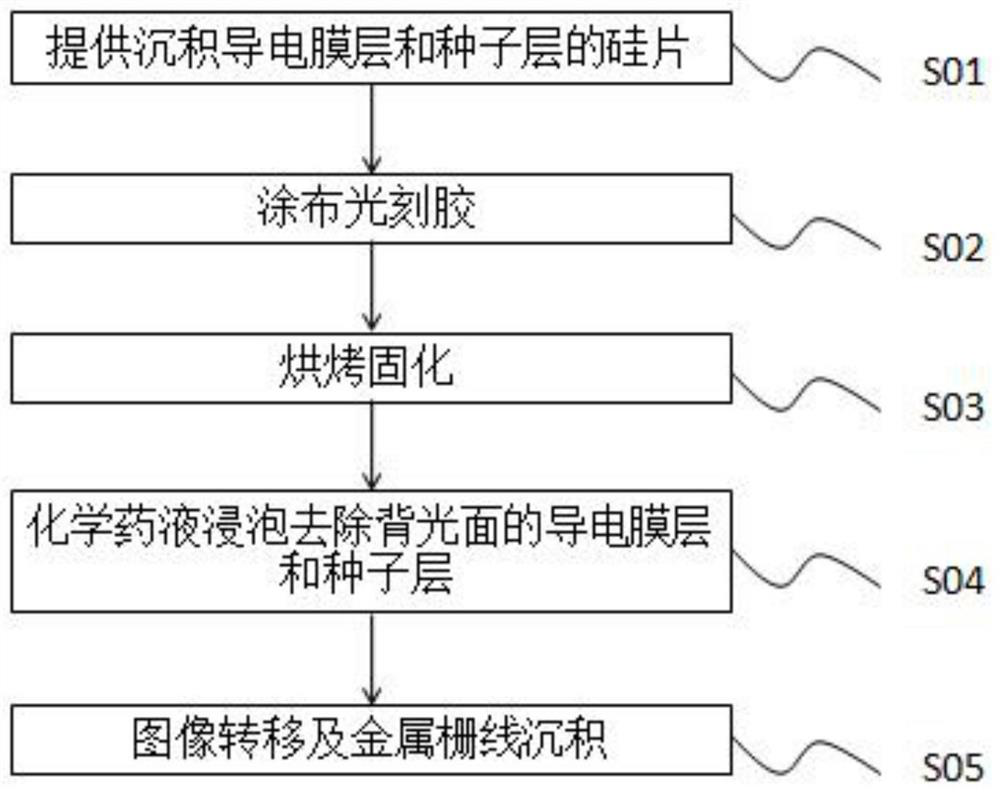

[0029] refer to Figure 1-Figure 5 , a method for preparing a solar cell, comprising the following steps:

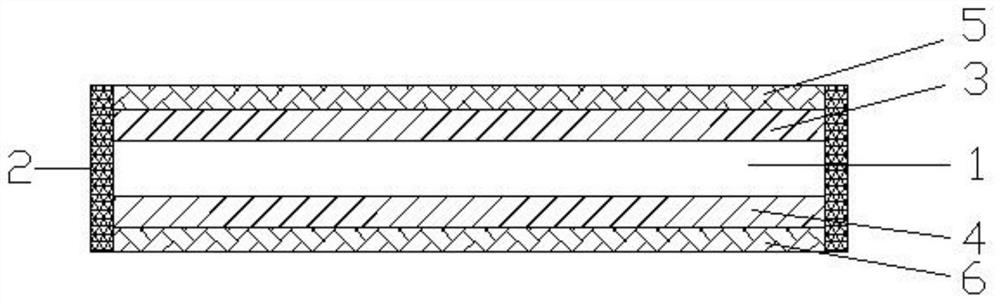

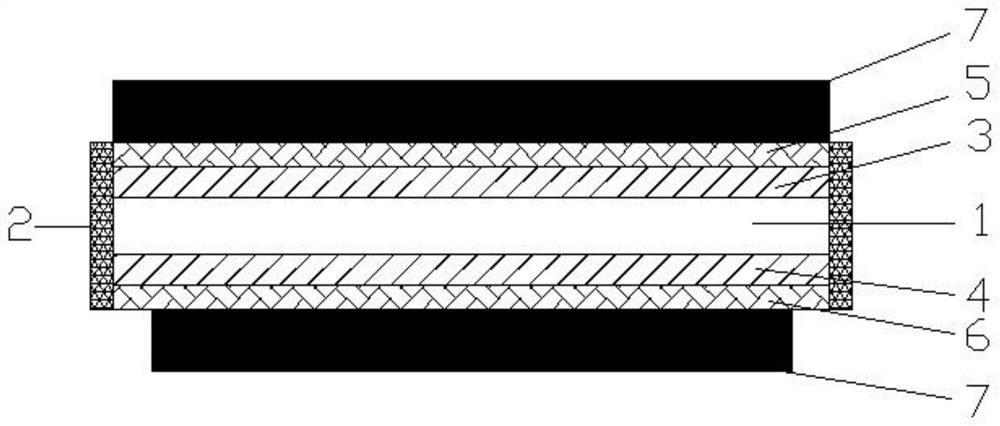

[0030] S01, providing a silicon wafer with a conductive film layer and a seed layer deposited on the light incident surface and the backlight surface; when the light incident surface of the silicon wafer 1 is an N-side conductive film layer 3 and a seed layer 5, the backlight surface is P Surface conductive film layer 4, seed layer 6; When the light incident surface is P-side conductive film layer 3, seed layer 5, the backlight surface is N-side conductive film layer 4, seed layer 6. The conductive film layers 3 and 4 are transparent conductive oxide layers TCO with a thickness of 50-200nm; the seed layers 5 and 6 are at least one of Ag, Cu, Al and the like with a thickness of 50-150nm. Such as figure 2 As shown, conductive film layers 3, 4 and seed layers 5, 6 have been deposited on the light incident surface and the backlight surface of the silicon wafer 1, and ther...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com