Transparent conductive oxide film based on TiN interlayer doping

An oxide film, transparent conductive technology, applied in the direction of the conductive layer on the insulating carrier, can solve the problems of low conductivity, low light loss, low conductivity, etc., to increase the light absorption area, good conductivity, and improve device performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

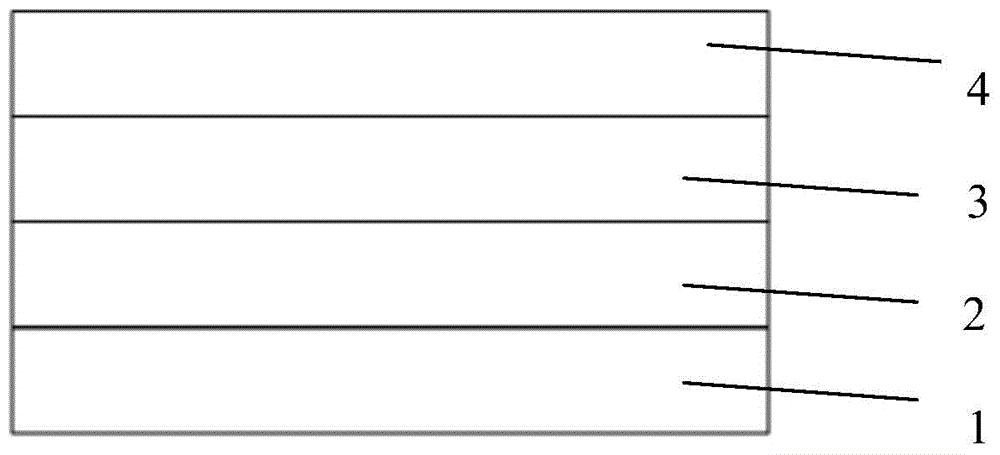

[0022] A transparent conductive oxide film based on TiN interlayer doping, including a substrate 1 (the substrate in this embodiment is a glass substrate), on which a lower transparent conductive layer 2 and an interlayer 3 are grown sequentially from bottom to top And the upper transparent conductive layer 4, the lower transparent conductive layer 2 and the upper transparent conductive layer 4 are transparent conductive oxide layers, wherein the thickness of the lower transparent conductive layer 2 and the upper transparent conductive layer 4 are both ITO films, and the thickness is 30nm. In this implementation, the interlayer 3 is a TiN layer with a thickness of 8 nm.

[0023] The transparent conductive oxide film based on TiN interlayer doping in this embodiment is prepared by the following steps:

[0024] (1) A layer of ITO film is grown by magnetron sputtering on the glass substrate after cleaning (sequentially cleaned by acetone, ethanol, and deionized water for 10 minut...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com