a condenser lens

A condensing lens and lens technology, applied in the field of condensing lenses, can solve the problems of reduced light output efficiency and light intensity at the center of the spot, increased mold difficulty, and reduced yield rate, etc. The effect of uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

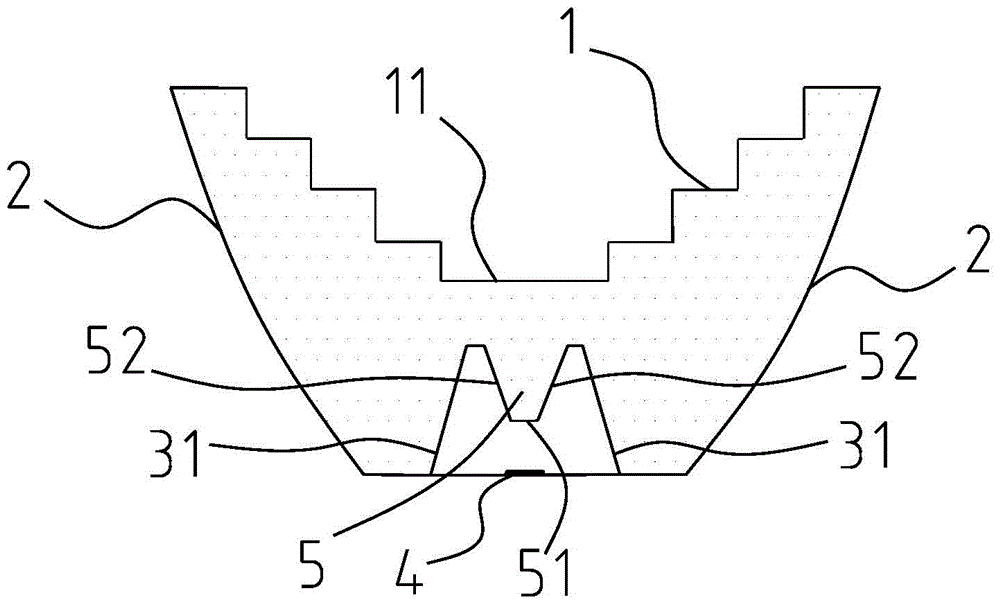

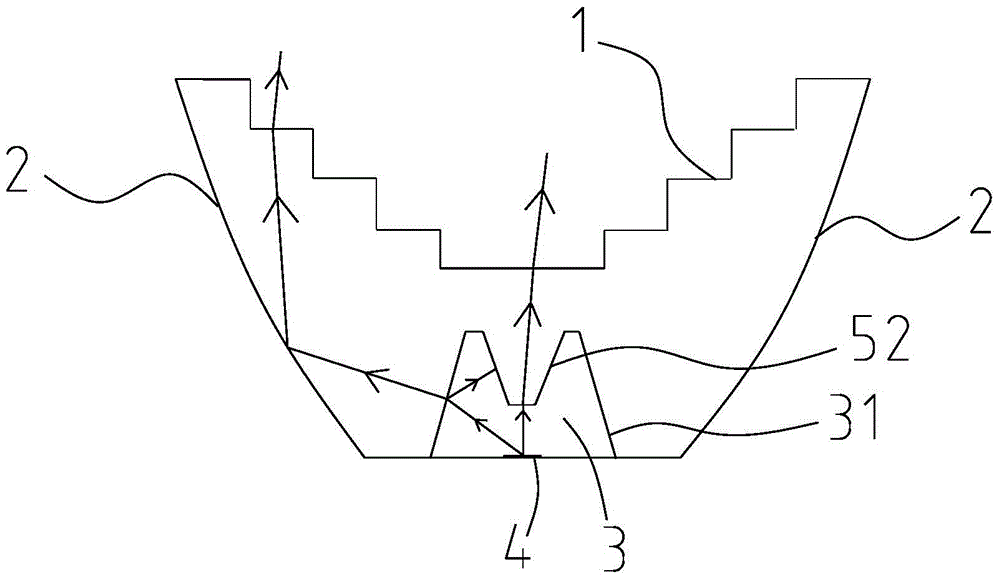

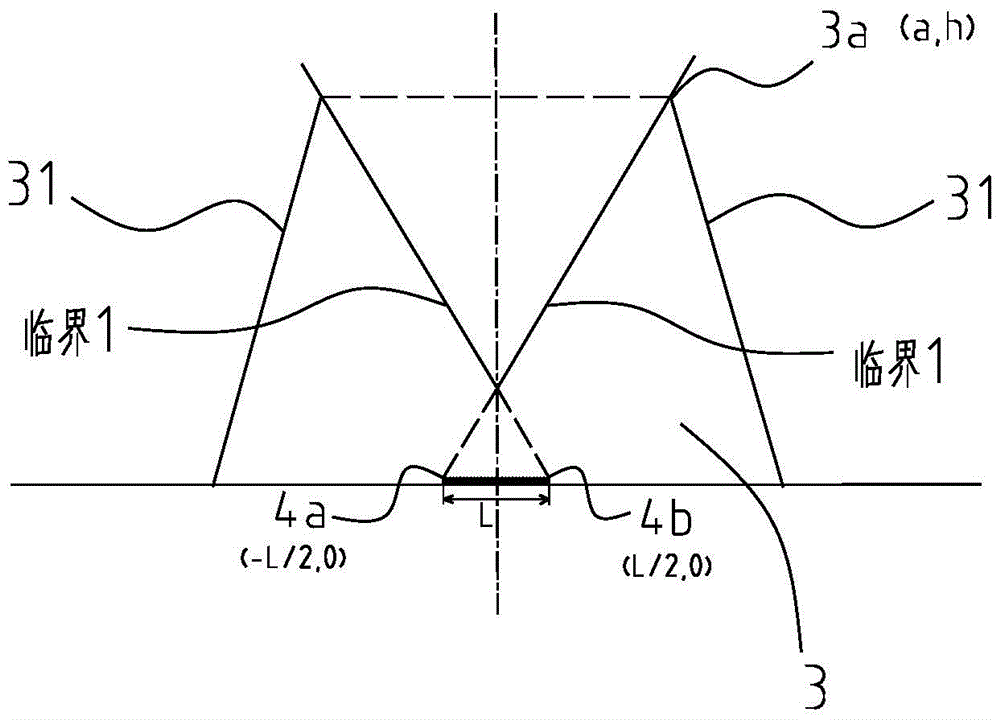

[0040] Refer to attached figure 1 to attach Figure 4 As shown, a condenser lens, the lens is a cup-shaped structure, and the inner diameter of the cup-shaped structure gradually decreases from the top to the bottom. The lens includes a light exit surface 1, a side curved surface 2 and a light incident surface, the light exit surface 1 is located at the top of the lens, one side of the side curved surface 2 is connected to the light exit surface 1, and the other side of the side curved surface 2 is connected to the light exit surface. The light incident surface is connected, and the inner wall of the side curved surface 2 is a total reflection surface. The light incident surface is located at the bottom of the lens and is recessed in the lens to form an inner cavity 3 for accommodating the light source, and the inner cavity 3 covers the light source 4 . The bottom of the cup-shaped structure is a circular surface, and the light source is a linear LED light-emitting element l...

Embodiment 2

[0048] The difference between this embodiment and Embodiment 1 is that: the second light incident surface is a convex surface 51a that is convex relative to the top of the lens, that is, the convex surface is convex downwards, refer to the attached Figure 6 As shown, the bottom surface 11a of the light-emitting surface is flat, and the convex surface 51a is combined with the bottom surface 11a of the light-emitting surface to gather and emit the light in the central part of the light source without being scattered or lost, thus obtaining more High central light intensity. The condenser lens of this embodiment can achieve the same effect of blocking stray light.

[0049] Other technical features are the same as those in Embodiment 1, and can achieve the same technical effect, and will not be described in detail here.

Embodiment 3

[0051] The difference between this embodiment and Embodiment 1 is that the second light-incident surface is a convex surface 51b that is raised relative to the bottom surface of the lens, that is, the convex surface is raised upwards, and the bottom surface 11b of the light-emitting surface is raised upwards relative to the bottom surface of the lens. surface, see attached Figure 7 As shown, the light projected onto the second light incident surface is refracted into the lens through the convex surface 51b, and emerges from the bottom surface 11b of the light exit surface. The convex surface 51b is combined with the bottom surface 11b of the light exit surface to achieve a certain focusing effect, which can The light in the central part of the light source is gathered and emitted without being scattered or lost, thus obtaining a higher and brighter central light intensity. The condenser lens of this embodiment can achieve the same effect of blocking stray light.

[0052] Oth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com