Solar battery structure for group II to V polycrystal semiconductors and manufacture method thereof

A technology of solar cells and manufacturing methods, applied in semiconductor devices, circuits, photovoltaic power generation, etc., can solve problems such as high chip costs, achieve the effects of increasing area, improving conversion efficiency, and increasing light absorption area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The above and other technical features and advantages of the present invention will be described in more detail below in conjunction with the accompanying drawings.

[0033] The present invention provides a solar cell structure of III-V semiconductors and a manufacturing method thereof. The solar cell can be applied to wall boards and roofs of buildings, etc., to receive sunlight to absorb solar energy and convert it into daily usable electrical energy .

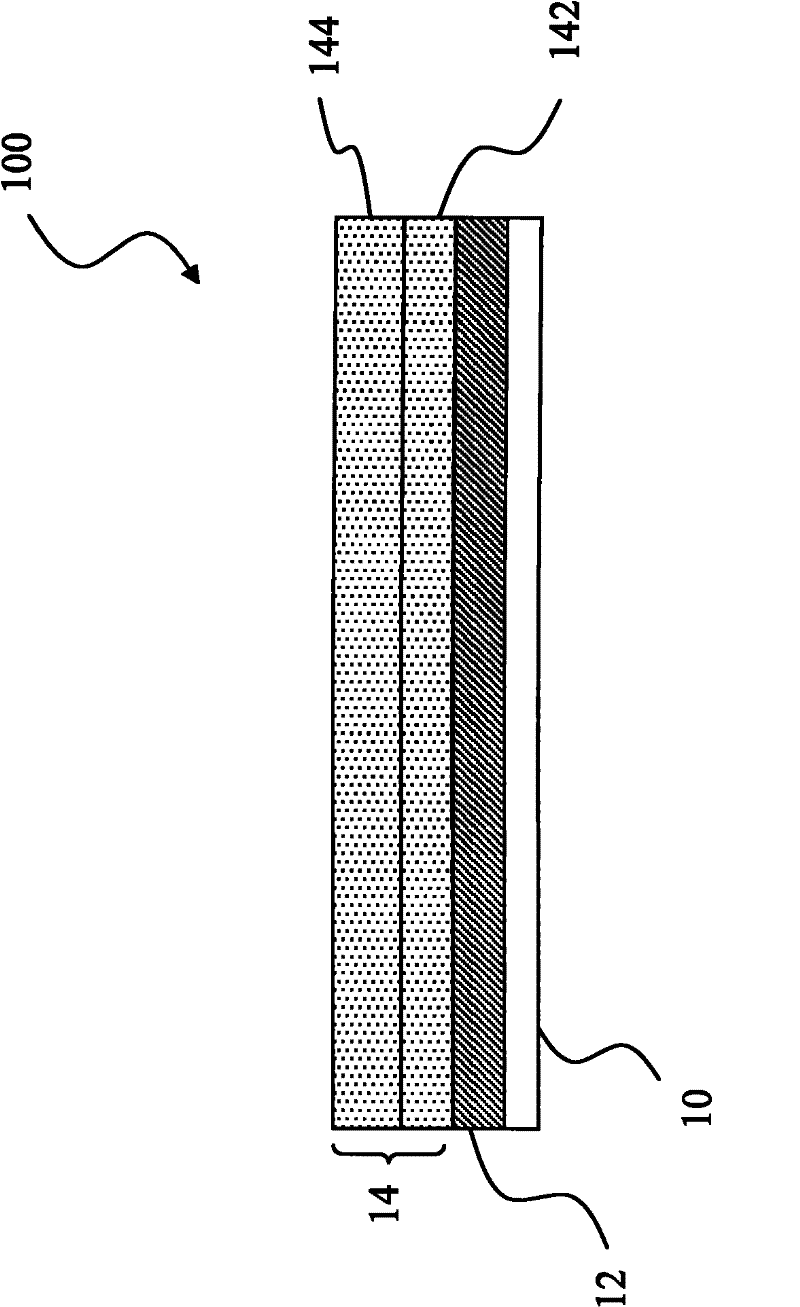

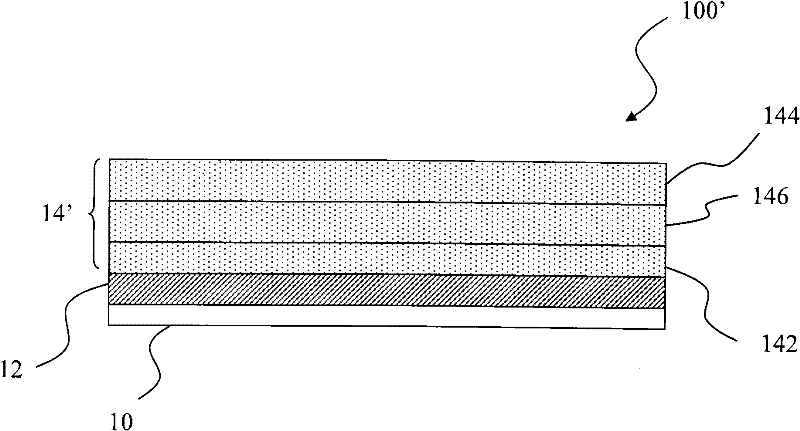

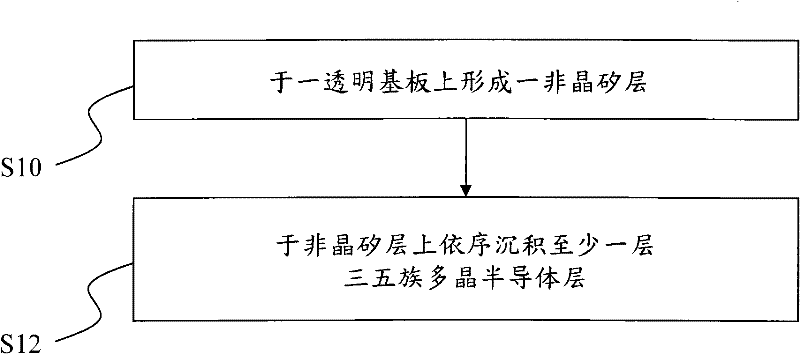

[0034] figure 1 It is a schematic diagram of a solar cell structure 100 of the present invention, the solar cell includes a transparent substrate 10, an amorphous silicon layer 12 and at least one Group III-V polycrystalline semiconductor layer (Group III-V polycrystalline semiconductor) 14, wherein the transparent substrate 10 The material is glass, quartz, transparent plastic or single crystal alumina, and the amorphous silicon layer 12 is formed on the transparent substrate 10; the material of the III-V polycrysta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com