Bismuth-based semiconductor photocatalyst and preparation method thereof

A photocatalyst and semiconductor technology, applied in the field of bismuth series semiconductor photocatalyst and its preparation, can solve the problems such as limiting the utilization rate of light, and achieve the effects of large market promotion value, narrow band gap, and efficient utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

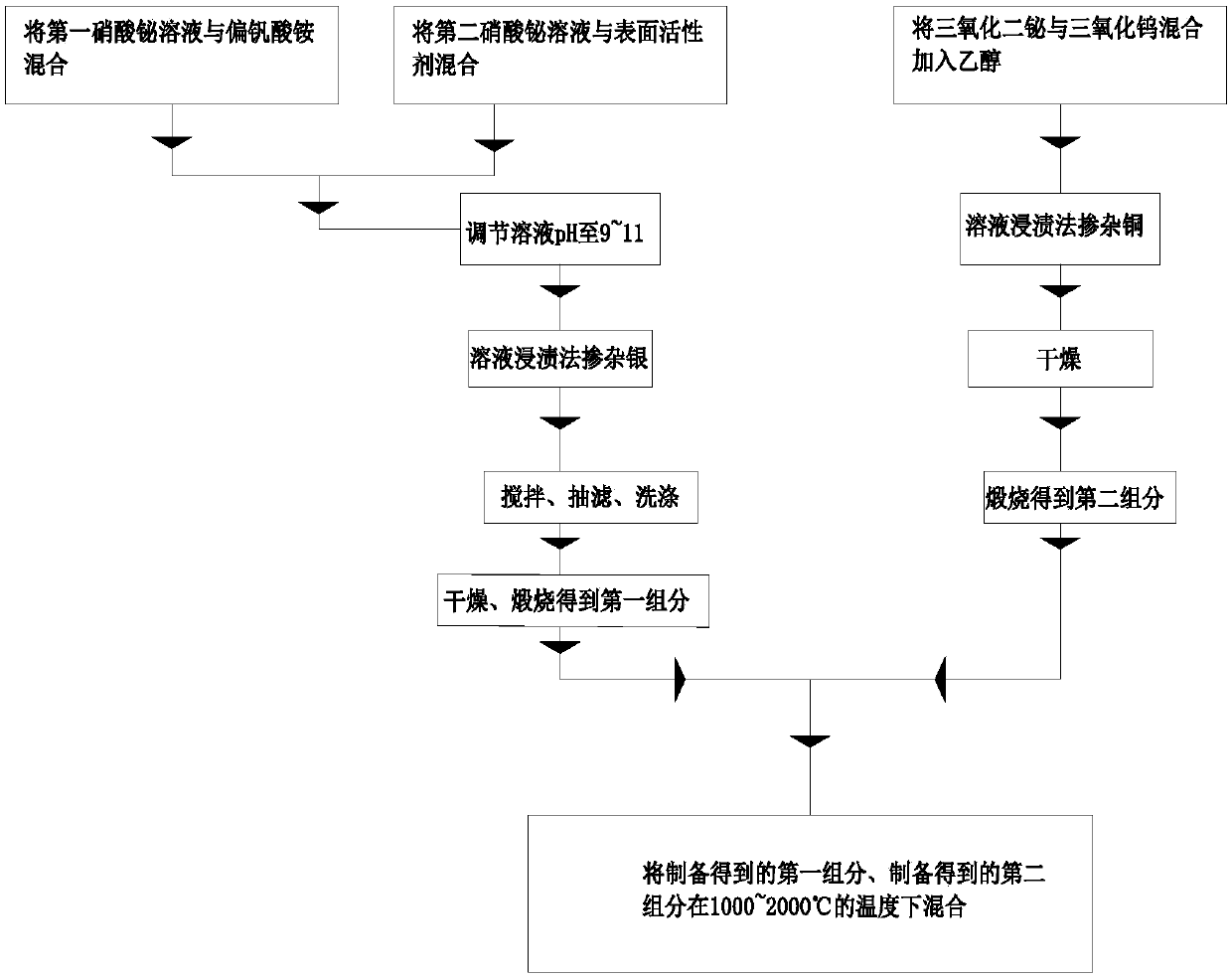

[0026] A preparation method of a bismuth-based semiconductor photocatalyst, comprising:

[0027] Mixing the first bismuth nitrate solution with a volume to weight ratio of 3:53 to 72 mL / g and a concentration of 3 to 5 moL / L with ammonium metavanadate to obtain a first mixed solution;

[0028] Mixing the second bismuth nitrate solution with a volume-to-weight ratio of 1:43-67mL / g and a concentration of 3-5moL / L with a surfactant to obtain a second mixed solution;

[0029] mixing the first mixed solution with the second mixed solution to obtain a third mixed solution, and then adjusting the pH to 9-11;

[0030] The third mixed solution after adjusting the pH is doped with silver according to the volume-to-weight ratio of 1:0.01-0.03mL / g by impregnation method to obtain the fourth mixed solution, and the fourth mixed solution is stirred and pumped in sequence. Obtain the first component after filtering, washing for the first time, washing for the second time, drying for the firs...

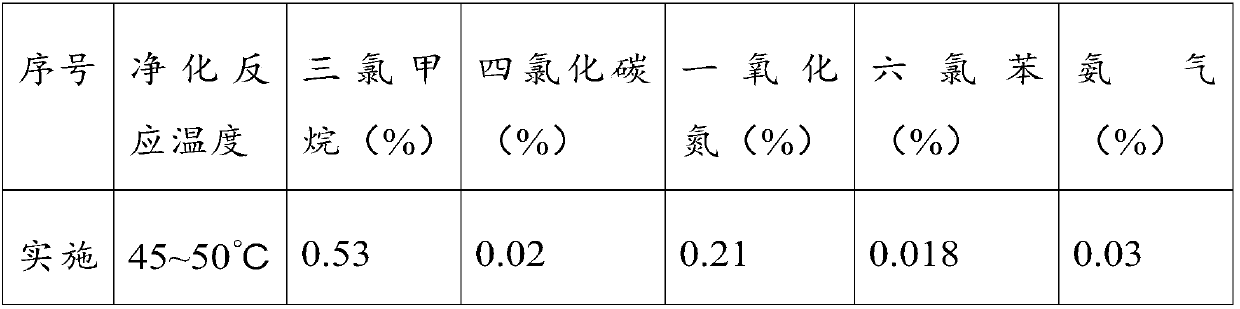

Embodiment 1

[0052] This embodiment provides a bismuth-based semiconductor photocatalyst, which is prepared by the following method:

[0053] With a weight ratio of 1:2 Bi(NO 3 ) 3 ·5H 2 O and NH 4 VO 3 After mixing, add the nitric acid solution of 0.2moL / L to make the first bismuth nitrate solution and the second bismuth nitrate solution, and the nitric acid solution and Bi(NO 3 ) 3 ·5H 2 The volume-to-weight ratio of O is 1:0.5 mL / g.

[0054] Mixing the first bismuth nitrate solution and ammonium metavanadate with a concentration of 3moL / L of 3:53mL / g to obtain the first mixed solution;

[0055] After mixing the second bismuth nitrate solution of 3moL / L with a surfactant in a volume-to-weight ratio of 1:43mL / g, the second mixed solution is obtained;

[0056] Drop the first mixed solution into the second mixed solution at a rate of 3g / S and mix to obtain the third mixed solution, then adjust the pH to 9;

[0057] The third mixed solution after adjusting the pH is mixed with silve...

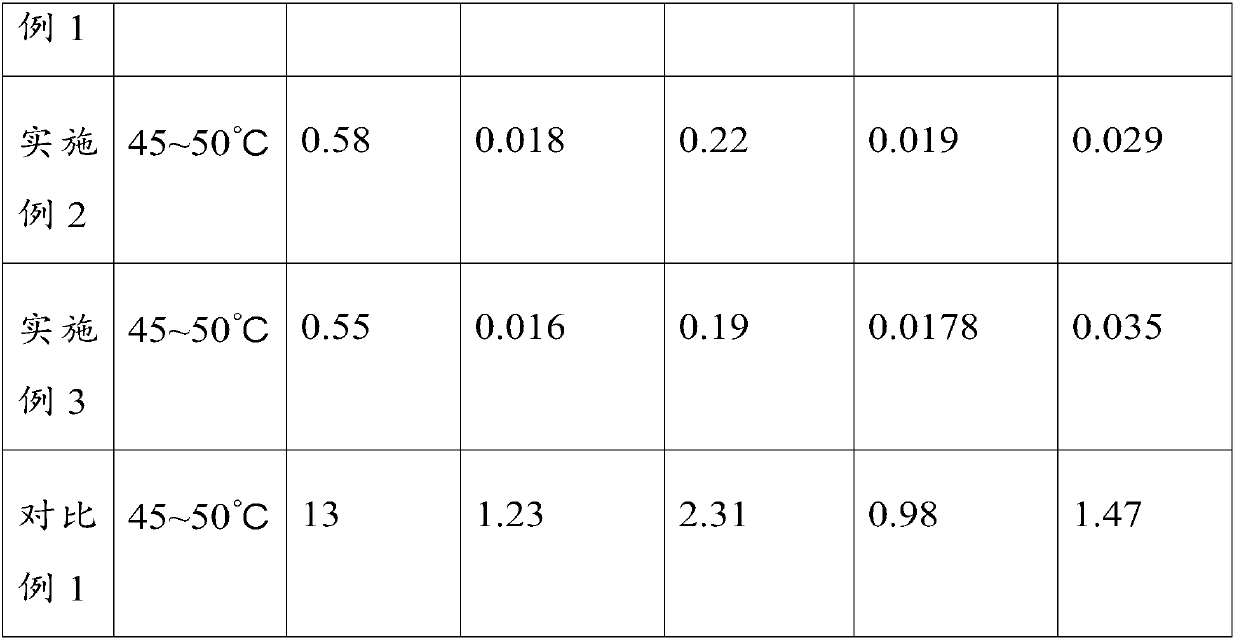

Embodiment 2

[0062] This embodiment provides a bismuth-based semiconductor photocatalyst, which differs from the bismuth-based semiconductor photocatalyst provided in Example 1 in that the bismuth-based semiconductor photocatalyst is prepared by the following method:

[0063] With a weight ratio of 1:3 Bi(NO 3 ) 3 ·5H 2 O and NH 4 VO 3 After mixing, add the nitric acid solution of 0.3moL / L to make the first bismuth nitrate solution and the second bismuth nitrate solution, and the nitric acid solution and Bi(NO 3 ) 3 ·5H 2 The volume-to-weight ratio of O is 1:0.6 mL / g.

[0064] Mixing the first bismuth nitrate solution and ammonium metavanadate with a concentration of 4moL / L of 3:61mL / g to obtain the first mixed solution;

[0065] After mixing the second bismuth nitrate solution of 4moL / L with a surfactant in a volume-to-weight ratio of 1:53mL / g, the second mixed solution is obtained;

[0066] Drop the first mixed solution into the second mixed solution at a rate of 4g / S and mix to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com