Synthesis method of silicon-based photochromic elastomer containing naphthol pyran with cross-linked structure

A photochromic and naphthol pyran technology, applied in the direction of color-changing fluorescent materials, chemical instruments and methods, etc., can solve the problems such as no silicon-based photochromic elastomers, and achieve rich varieties, excellent performance and simple operation. easy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

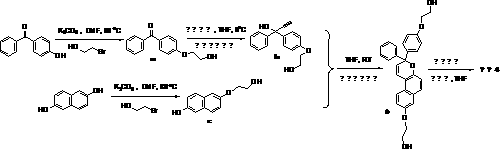

Method used

Image

Examples

Embodiment 1

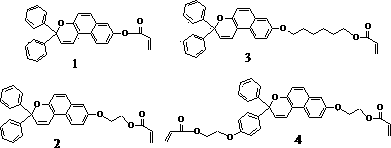

[0040] Example 1: In a 100ml three-necked flask equipped with a reflux condenser and a dropping funnel, add 1.5g of hydrogen-containing silicone oil, 25ml of toluene and 0.004g of chloroplatinic acid in water, and heat it after feeding argon for 15 minutes. When the temperature rises to 65 o At C, add 0.3g monomer dropwise 1 and 0.1g monomer 4 15ml of the toluene mixed solution was dropped within 2 hours, and then continued to be heated to reflux, and the reaction was stopped after 2 hours. Distill under reduced pressure to remove the remaining toluene, and dissolve the residue in a small amount of tetrahydrofuran solvent, remove the catalyst through an aluminum oxide column, and settle in cold methanol for 3 times to obtain a photochromic elastomer. The product is a solid substance with very low hardness , 1.64g, yield 86.3%. The structural formula of the product is as follows:

[0041]

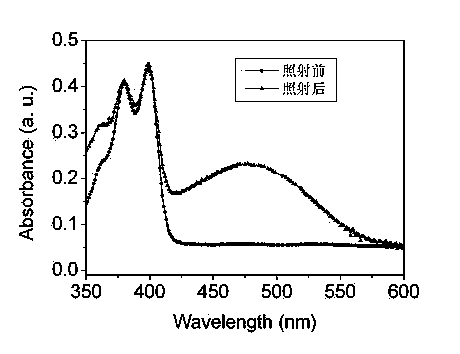

[0042] After the product is pressed into a film by a flat vulcanizer, the film ...

Embodiment 2

[0044] In a 100ml three-necked flask equipped with a reflux condenser and a dropping funnel, add 1.0g of hydrogen-containing silicone oil, 18ml of toluene and 0.003g of chloroplatinic acid aqueous solution, and heat it after feeding argon for 15 minutes. When the temperature rises to 80 o At C, add 0.2g monomer dropwise 2 and 0.08g monomer 4 10ml of the toluene mixed solution was dropped within 1.5 hours, and then continued to be heated to reflux, and the reaction was stopped after 3 hours. Distill under reduced pressure to remove the remaining toluene, and dissolve the residue in a small amount of tetrahydrofuran solvent, remove the catalyst through an aluminum oxide column, and settle in cold methanol for 3 times to obtain a photochromic elastomer. The product is a solid substance with very low hardness , 0.98g, yield 76.5%. The structural formula of the product is as follows:

[0045]

Embodiment 3

[0047] In a 100ml three-necked flask equipped with a reflux condenser and a dropping funnel, add 1.2g of hydrogen-containing silicone oil, 25ml of toluene and an aqueous solution of 0.003g of chloroplatinic acid, and heat it after feeding argon for 15 minutes. 45 o At C, add 0.25g monomer dropwise 3 and 0.1g monomer 4 The toluene mixed solution of 15ml is dripped within 2.5 hours, then continues to be heated to reflux, stops reaction after 3 hours. Distill under reduced pressure to remove the remaining toluene, and dissolve the residue in a small amount of tetrahydrofuran solvent, remove the catalyst through an aluminum oxide column, and settle in cold methanol for 3 times to obtain a photochromic elastomer. The product is a solid substance with very low hardness , 1.28g, yield 82.6%. The structural formula of the product is as follows:

[0048]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com