Automatic bouncing structure for screw type electric coupler

An electrical connector and screw technology, which is applied in the field of automatic pop-up structure, can solve the problems of unfavorable miniaturization development of electrical connectors, increase in the lateral size of plastic bodies, restricting the expansion and application of electrical connectors, etc., and is conducive to the development of miniaturization. , Reduce the horizontal size, the effect of simple assembly operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

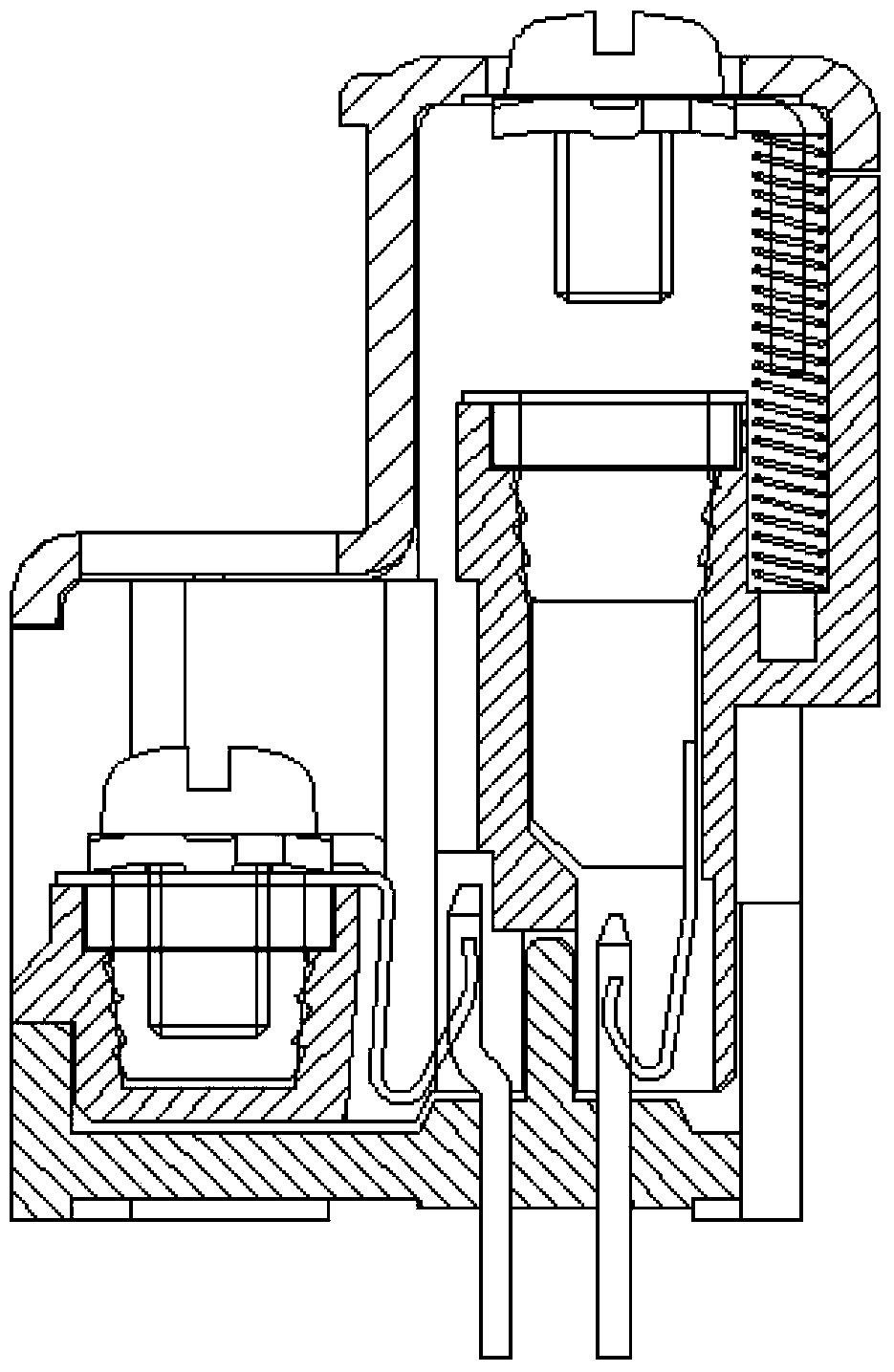

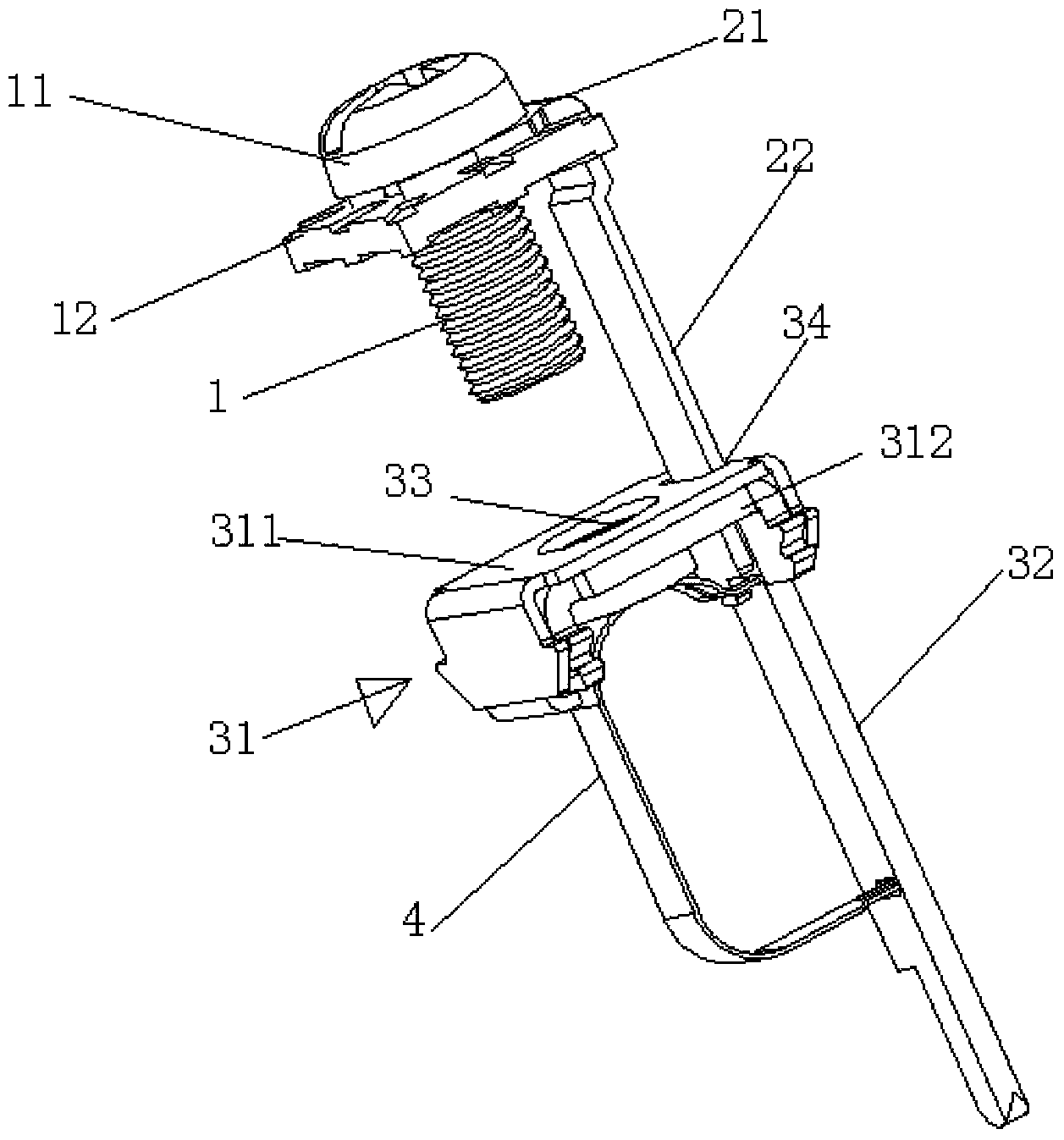

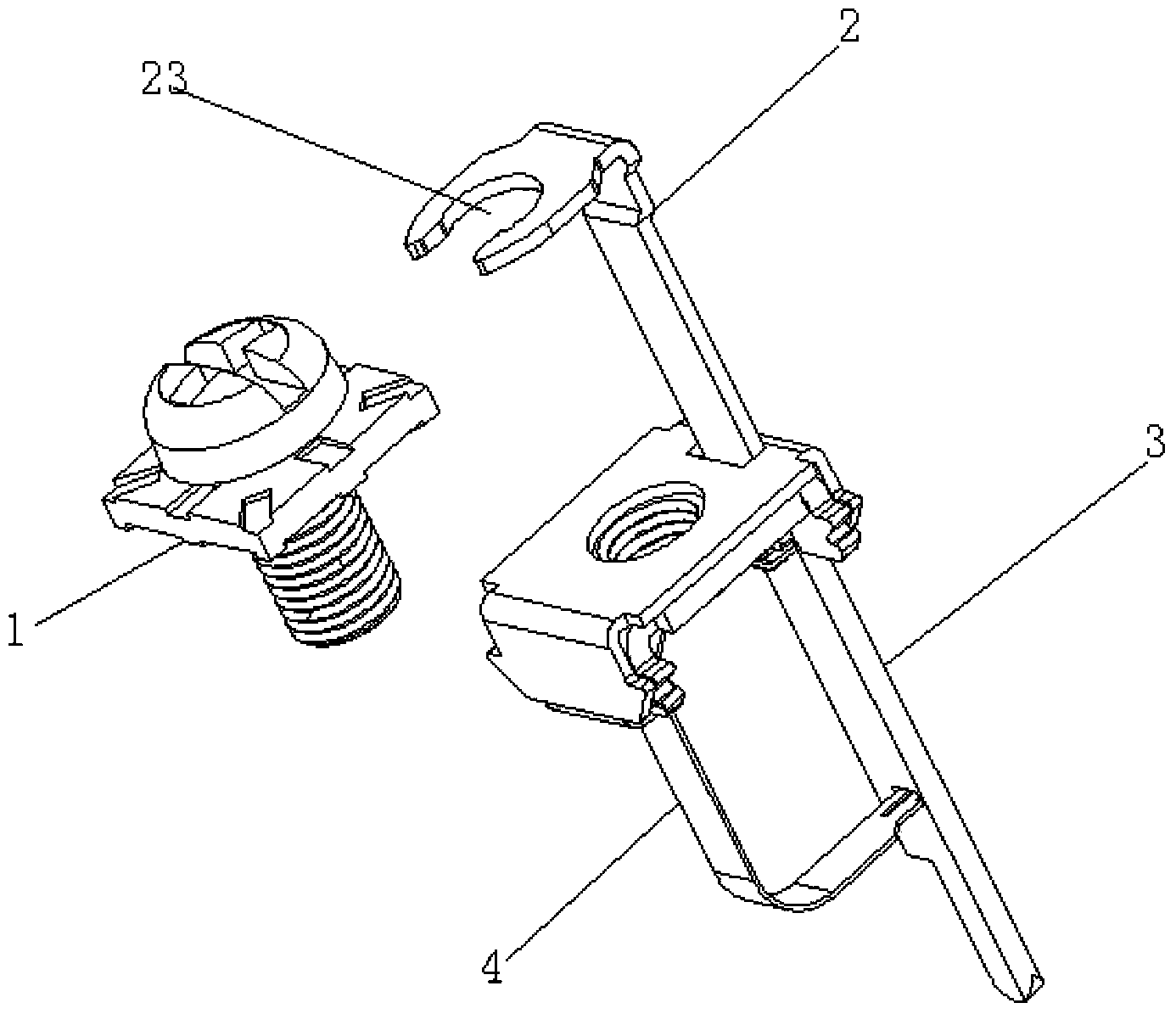

[0021] Such as figure 2 and image 3 As shown, an automatic pop-up structure of a screw 1 type electrical connector, based on the direction of use, includes a screw 1, a supporting terminal 2, an L-shaped conductive plate 3 and a spring piece 4.

[0022] The conductive plate 3 includes a flat plate portion 31 arranged horizontally and a foot portion 32 arranged vertically. The flat plate portion 31 is in the shape of a sheet, and the foot portion 32 is in the shape of a rod. One end of the foot portion 32 is fixedly connected to one side of the flat portion 31; The middle part of the part 31 is provided with a screw hole 33 matching the screw 1, and the side of the screw hole 33 close to the foot part 32 is provided with a first through hole 34; the screw 1 is located above the flat part 31 of the conductive plate 3, facing the screw ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com