Colored curable composition and color filter

A hardening and composition technology, applied in the field of color filters, can solve problems such as difficult to further improve contrast, brightness, poor dispersion stability, and increased viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

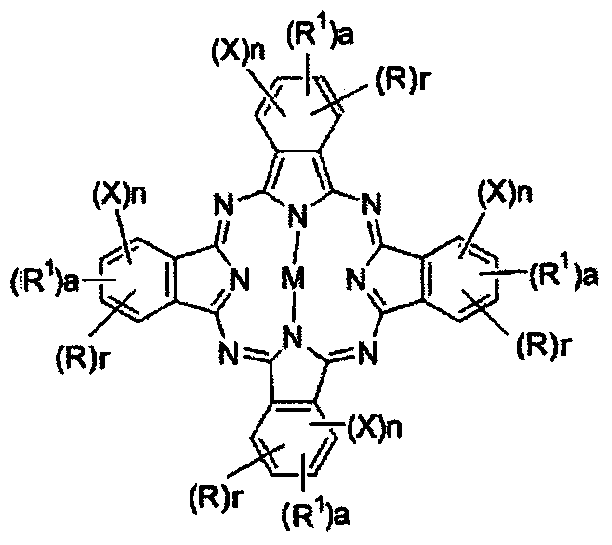

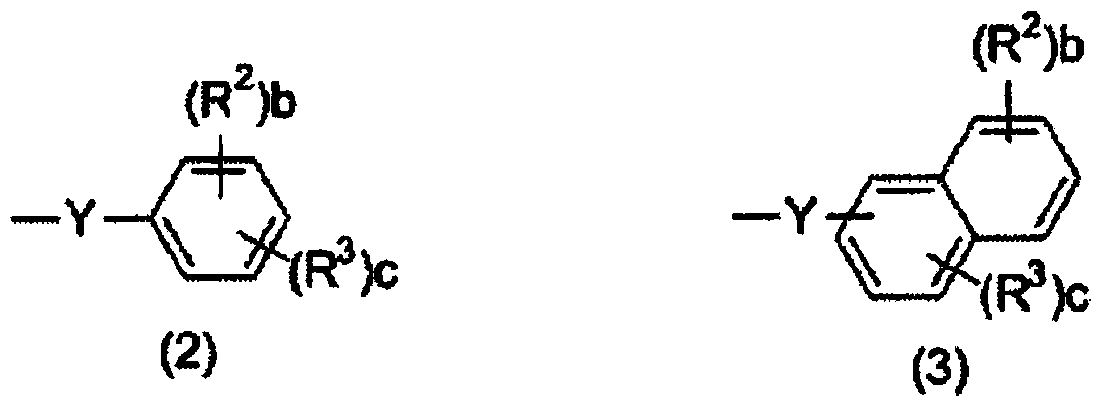

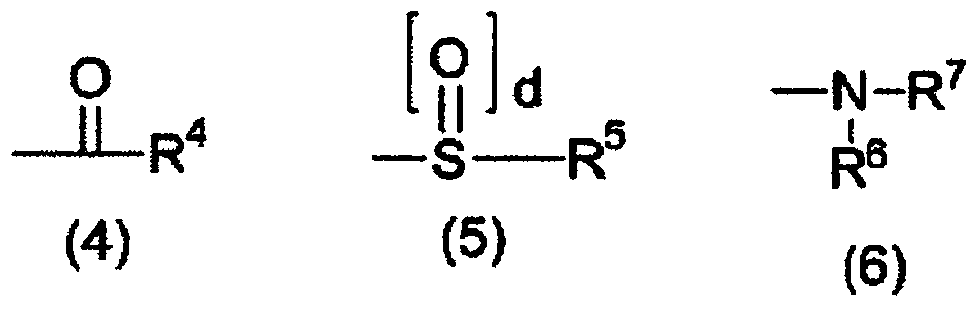

Method used

Image

Examples

preparation example Construction

[0302] [Manufacturing Method of Colored Curable Composition]

[0303] The colored curable composition of the present invention can be prepared by mixing the above-mentioned components and optional optional components.

[0304] In addition, when preparing the curable colored composition, each component constituting the curable colored composition may be prepared at one time, or may be sequentially prepared after dissolving and dispersing each component in a solvent. In addition, there are no particular restrictions on the order of charging or operating conditions at the time of blending. For example, the composition can be prepared by dissolving and dispersing all the components in a solvent at the same time, and if necessary, two or more kinds of solutions and dispersions of the components can be prepared in advance, and these can be mixed at the time of use (at the time of coating) And prepared into composition.

[0305] The colored curable composition prepared as described...

Embodiment 1

[0429] For the phthalocyanine compound, the maximum absorption wavelength (λmax) in a chloroform solvent was measured using an ultraviolet-visible spectrophotometer (manufactured by Shimadzu Corporation, UV 2400-PC). The measurement results are shown in the following tables.

[0430] [Table 4]

[0431]

[0432]

[0433] Next, each component for preparing a colored curable composition is shown below.

[0434] (Y-1) 12.8 parts of C.I. Pigment Yellow 150, methyl methacrylate / methacrylic acid (80 / 20) [mass ratio] copolymer (weight average molecular weight: 12,000) and 7.2 parts of propylene glycol monomethyl Pigment dispersion obtained by mixing 80.0 parts of ether acetate and fully dispersing the pigment using a bead mill

[0435] (Y-2) Dissolving 10.0 parts of C.I. Solvent Yellow 162) in 90.0 parts of propylene glycol monomethyl ether acetate (manufactured by Wako Pure Chemical Industries, Ltd.)

[0436] (Y-3) Dissolving 10.0 parts by weight of the fol...

Embodiment 101

[0478] Production of green coloring film

[0479] (Preparation of colored curable composition (coating liquid))

[0480] The components in the following compositions were mixed to prepare a colored curable composition.

[0481]

[0482]

[0483]

[0484] After irradiating the colored film with a xenon lamp at 200,000 lux (lux) for 10 hours (corresponding to 2 million lux·h), the chromaticity change, that is, the ΔEab value was measured. When the ΔEab value is small, it means that the light resistance is excellent.

[0485]

[0486] After heating the colored film at 230° C. for 60 minutes, the chromaticity change, that is, the ΔEab value was measured. When the ΔEab value is small, it means that the light resistance is excellent.

[0487]

[0488] Utilize the same method as Example 1 to adjust the colored film, and then apply 50mJ / cm to the entire surface of the coating film through a mask 2 (illuminance is 20mW / cm 2 ) was exposed, and a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| absorption wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap