Two-segment-type automatic sealing straw

An automatic sealing, two-stage technology, applied in the field of straws, can solve the problems of contaminated beverages, lack of sealing and leak-proof functions, etc., and achieve the effect of convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

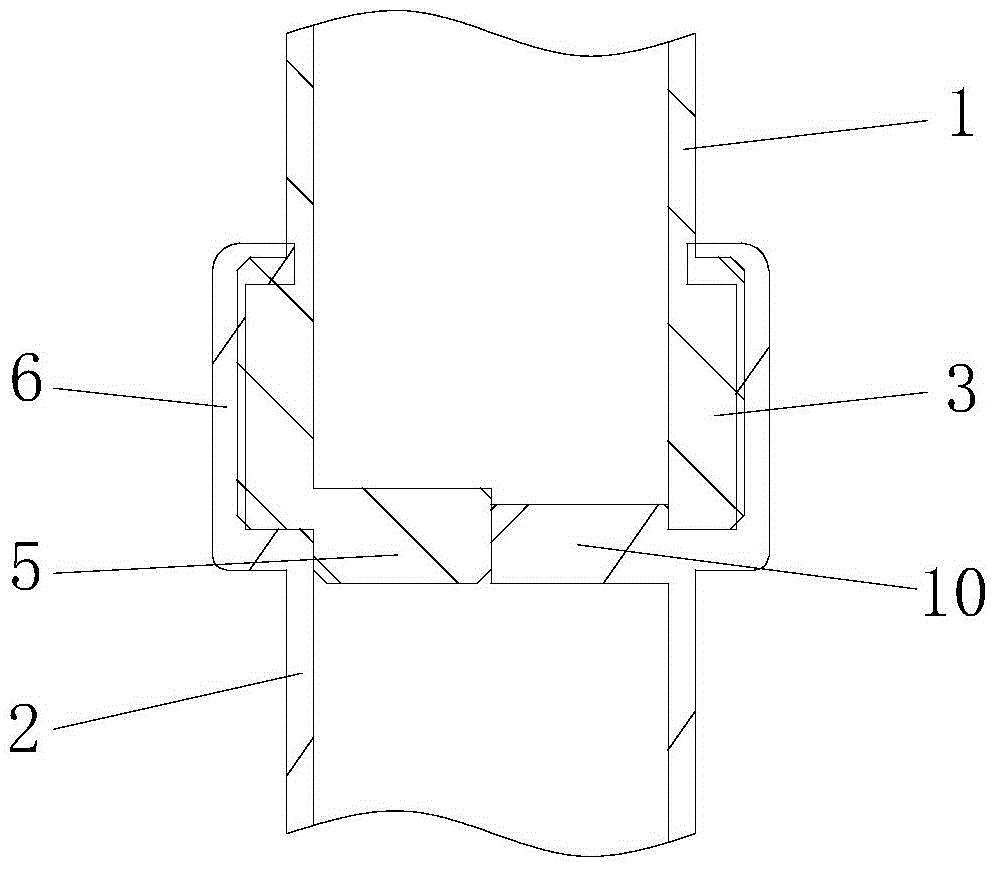

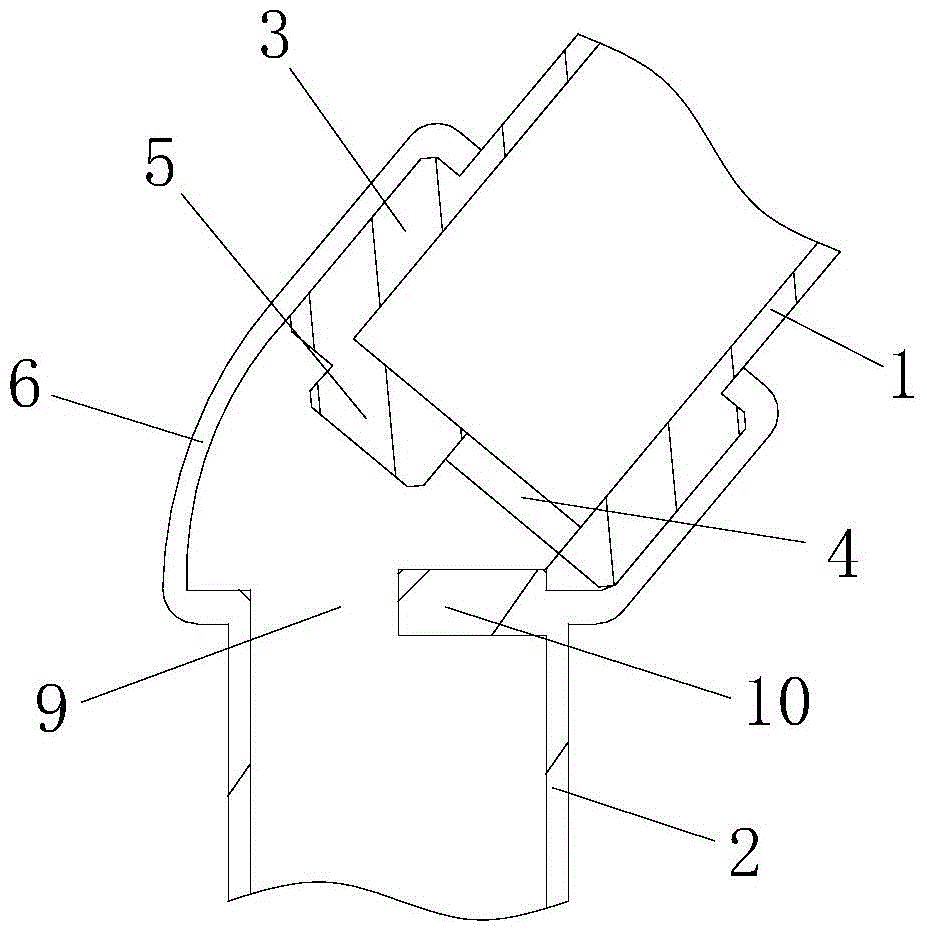

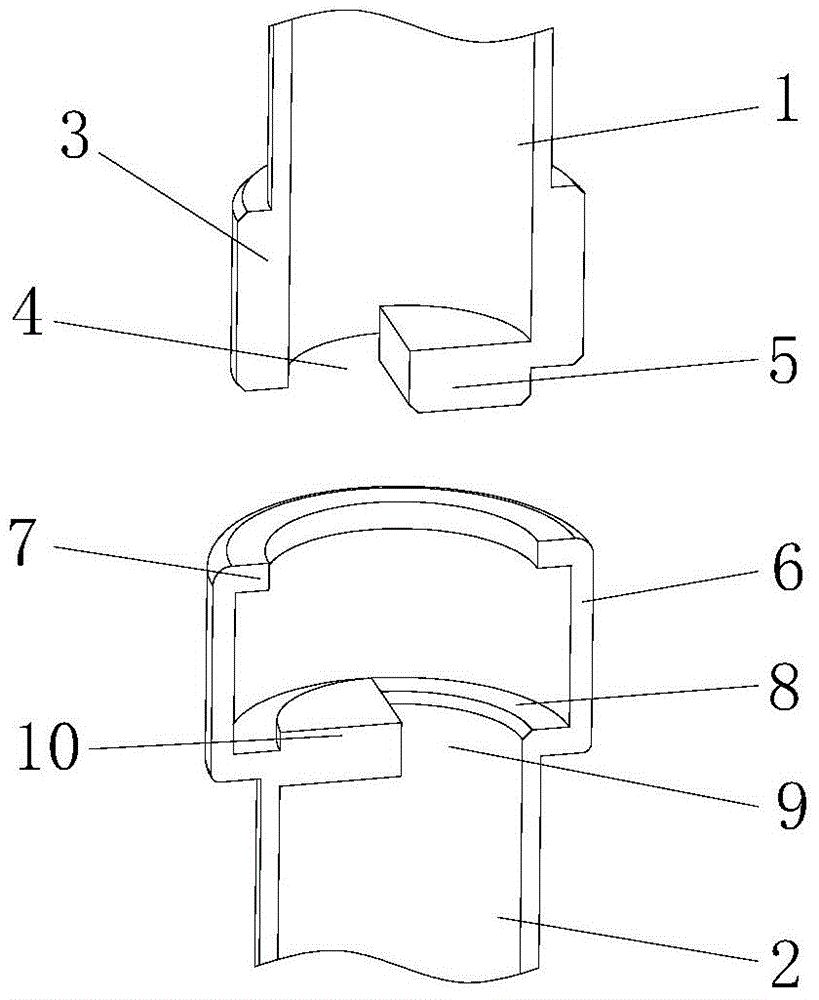

[0013] refer to Figure 1 to Figure 4 , a two-stage self-sealing straw, consisting of an upper pipe 1 and a lower pipe 2, the lower end of the upper pipe 1 is provided with a protruding upper connecting end 3, and the lower end of the upper pipe 1 is provided with a first outlet Nozzle 4 and first protrusion 5; the upper end of the lower pipe 2 is provided with a lower connection end 6 adapted to the upper connection end 3, and the upper end of the lower connection end 6 is provided with an inwardly turned buckle edge 7, The connection between the lower end of the lower connecting end 6 and the lower pipe 2 forms a limiting step 8. After assembly, the upper end of the upper connecting end 3 is against the buckle edge 7, and the lower end is against the limiting step 8.

[0014] The upper end of the lower pipe 2 is provided with a second water outlet 9 and a second protrusion 10. In a natural state, the first protrusion 5 is inserted into the second water outlet 9, and the seco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com