3d printer print head

A 3D printer and print head technology, applied in processing and manufacturing, liquid material additive processing, additive processing, etc., can solve problems such as difficult to achieve high-pressure rapid injection, difficult to achieve material diversity, and high production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in further detail below in conjunction with the embodiments and with reference to the accompanying drawings.

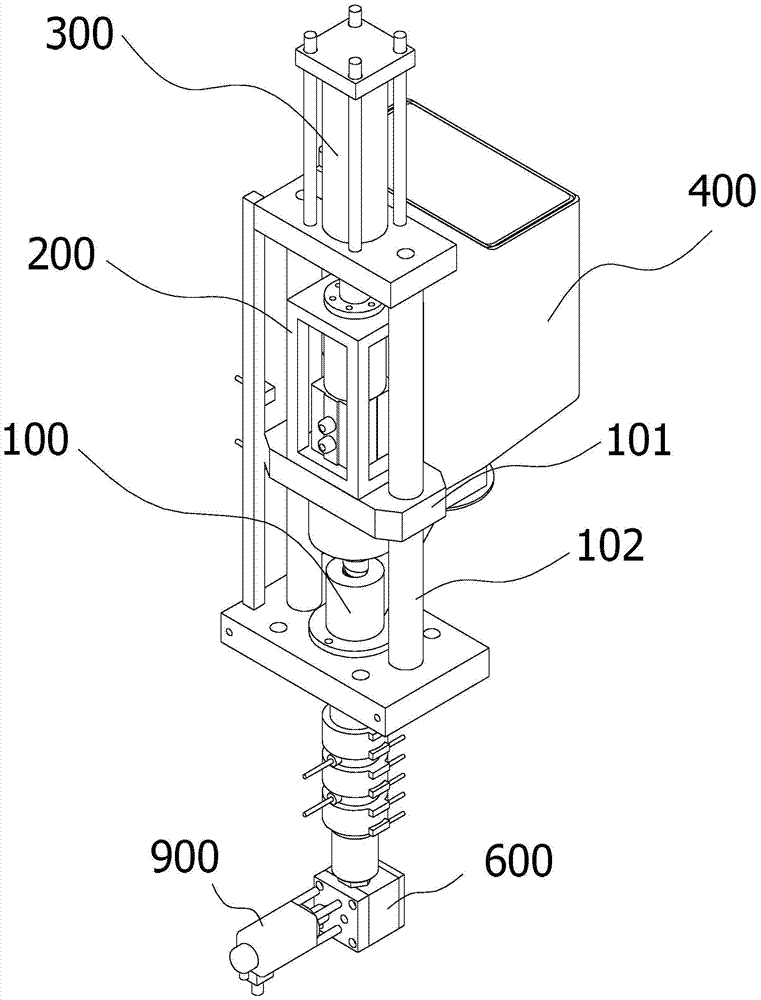

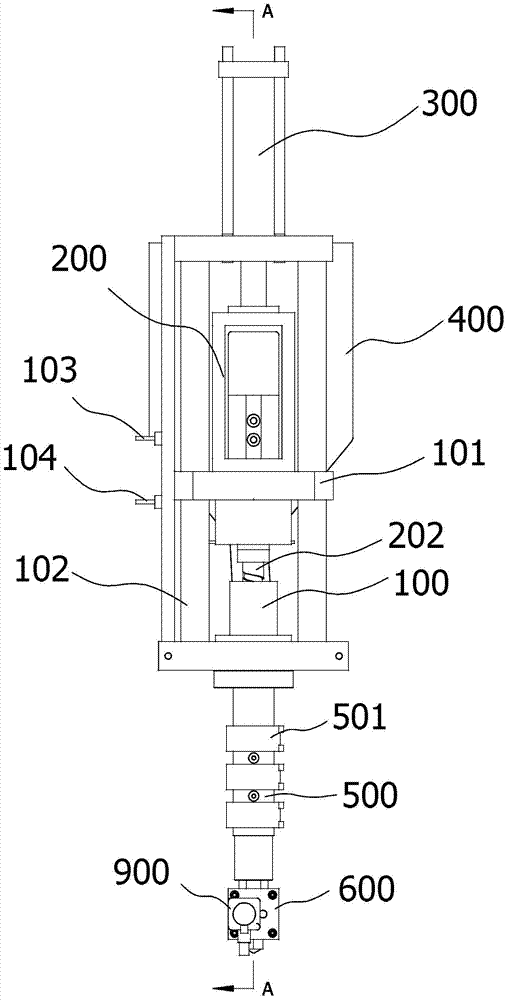

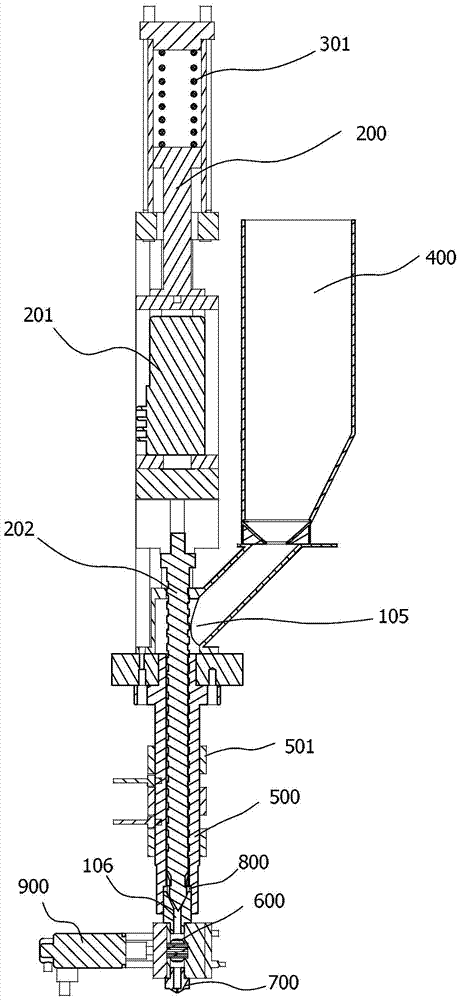

[0017] A print head for a 3D printer, please refer to Figure 1 to Figure 3 , including a housing 100, a feeding device 200 is arranged up and down in the housing 100, a pressure device 300 is arranged above the feeding device 200, and the outlet 106 of the feeding device 200 is communicated with by a volumetric metering pump 600 Nozzle 700, the feed device 200 includes a drive device 201 and a screw 202 driven to rotate by the drive device 201, a feed port 105 is arranged above the housing surrounding the screw rod 202, and a feed port 105 is arranged below the housing surrounding the screw rod 202 The end of the screw rod 202 is provided with a one-way valve 800 for the hot melt cavity 500 .

[0018] When the printing head is working, the granular, powdery or fluid raw material placed in the funnel 400 enters the casin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com