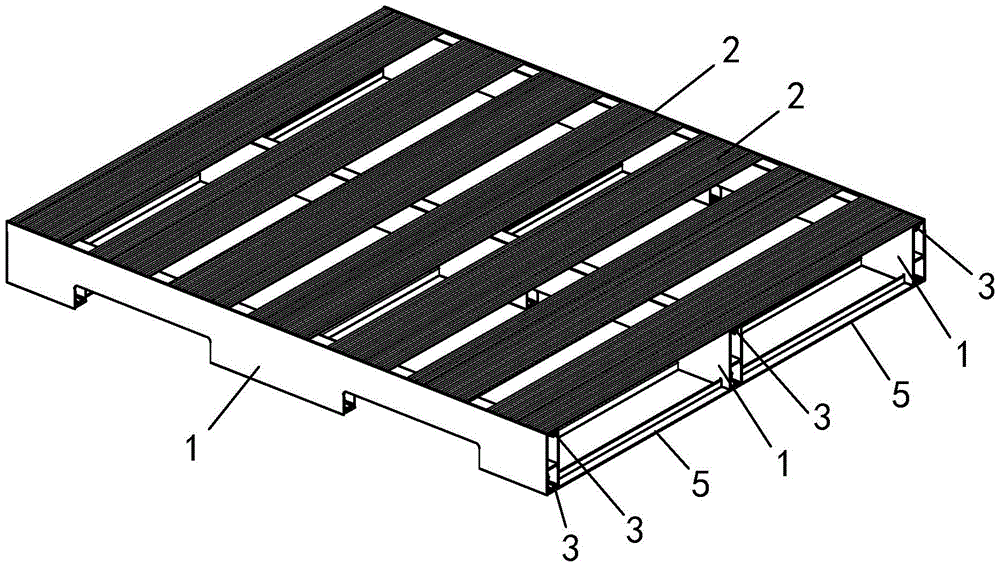

An assembled combined tray

A combined pallet technology, which is applied in the field of cargo transportation and storage pallets, can solve the problems of troublesome disassembly and installation, time-consuming and laborious, etc., and achieve the effect of convenient disassembly and assembly, not easy to lose, and long-term storage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

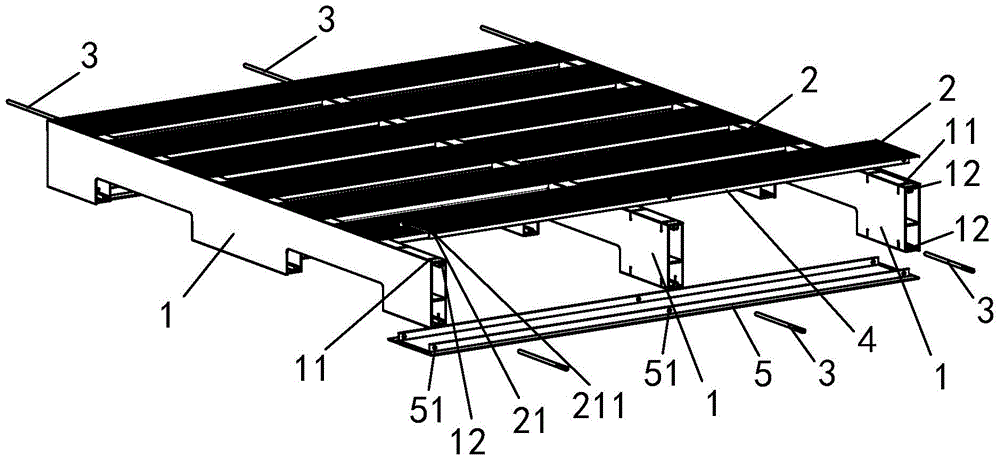

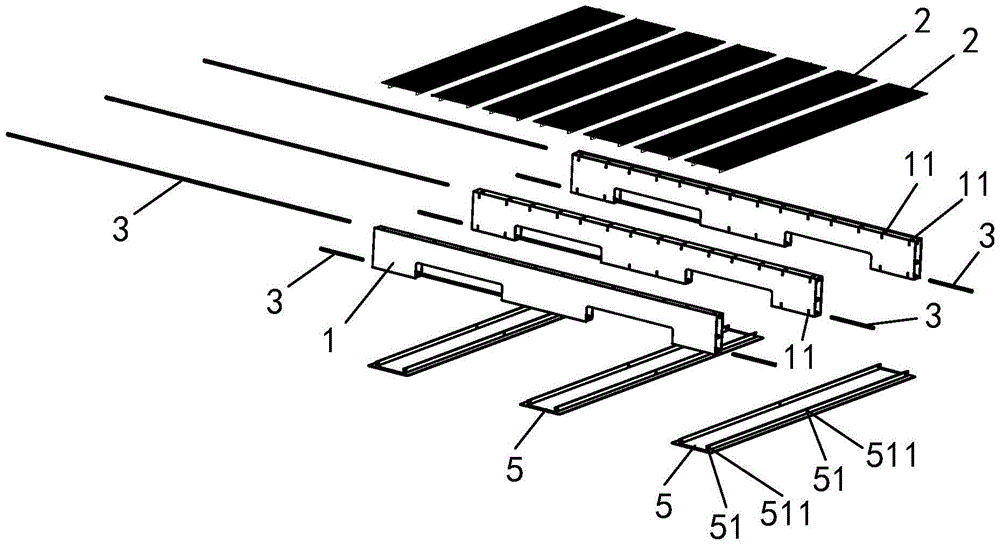

[0024] Example: such as Figure 1 to Figure 6 Shown:

[0025] An assembled and combined pallet, comprising a plurality of supporting beams 1 arranged side by side and a plurality of pallets 2 laid on the top surface of the supporting beams 1, the length direction of the pallets 2 is perpendicular to the length direction of the supporting beams 1.

[0026] Specific as figure 1 As shown in an example, there are three support beams 1 and seven pallets 2 .

[0027] see figure 2 — Figure 5 As shown, the support beam 1 is a hollow metal profile, preferably an aluminum alloy profile, and the top surface of each support beam 1 is provided with a plurality of slots 11 along the width direction of the support beam 1, and the upper part of each support beam 1 is along the The lengthwise direction of the supporting beam 1 is provided with a pin hole, and a pin 3 is pierced in the pin hole.

[0028] figure 2 It shows that the pin bar 3 is pulled out from the pin bar hole to make a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com