Medicine discharging device with overturning plate and ratchet type structure

A flap ratchet-type, drug-discharging device technology, which is applied to storage devices, transportation and packaging, can solve the problems of wrong drug quantity, continuous drug delivery, and inaccurateness, so as to achieve convenient and accurate delivery, rapidity and safety. Accuracy, fast and accurate release effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

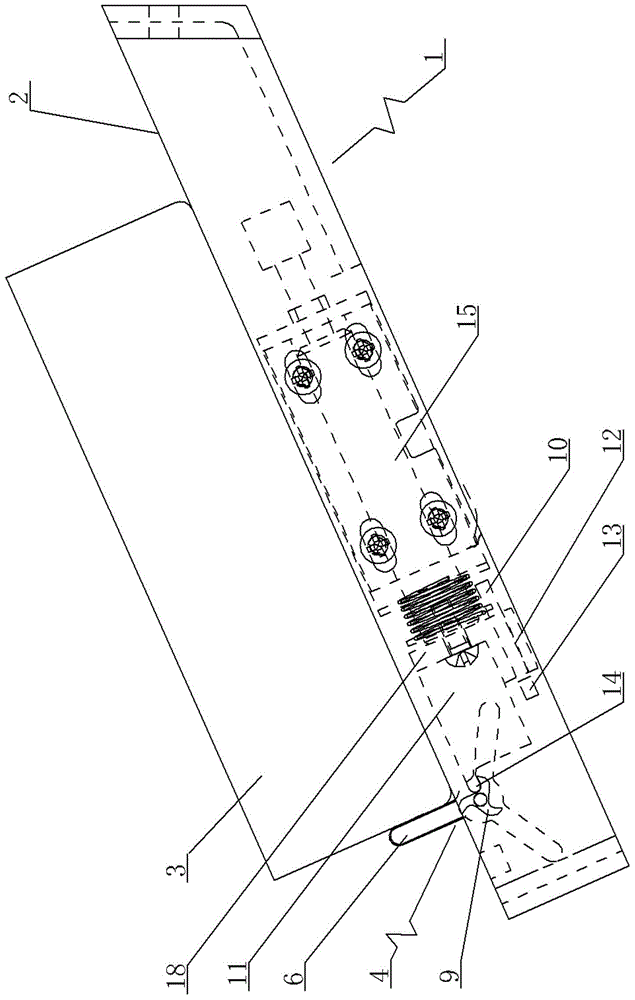

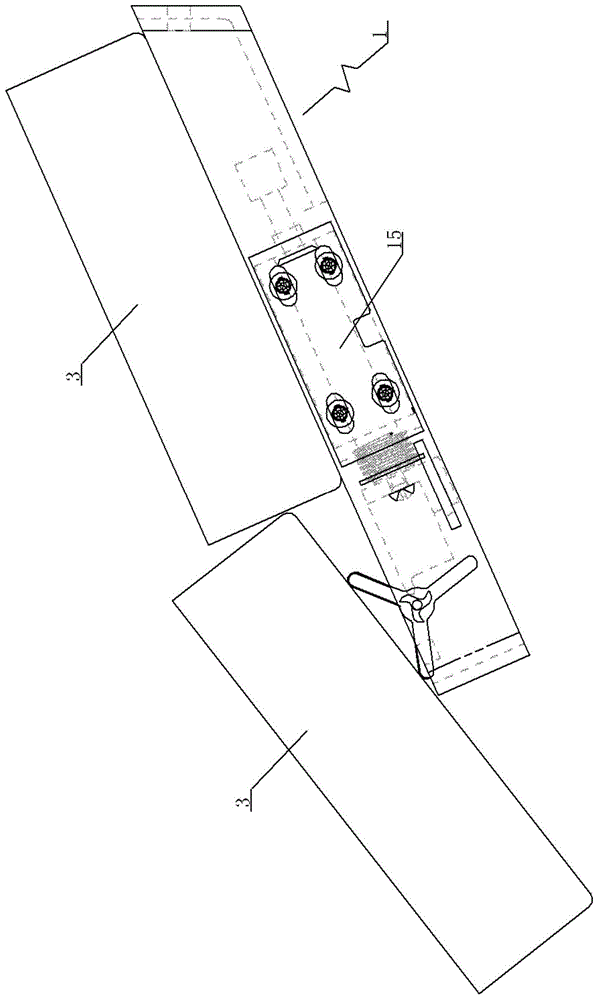

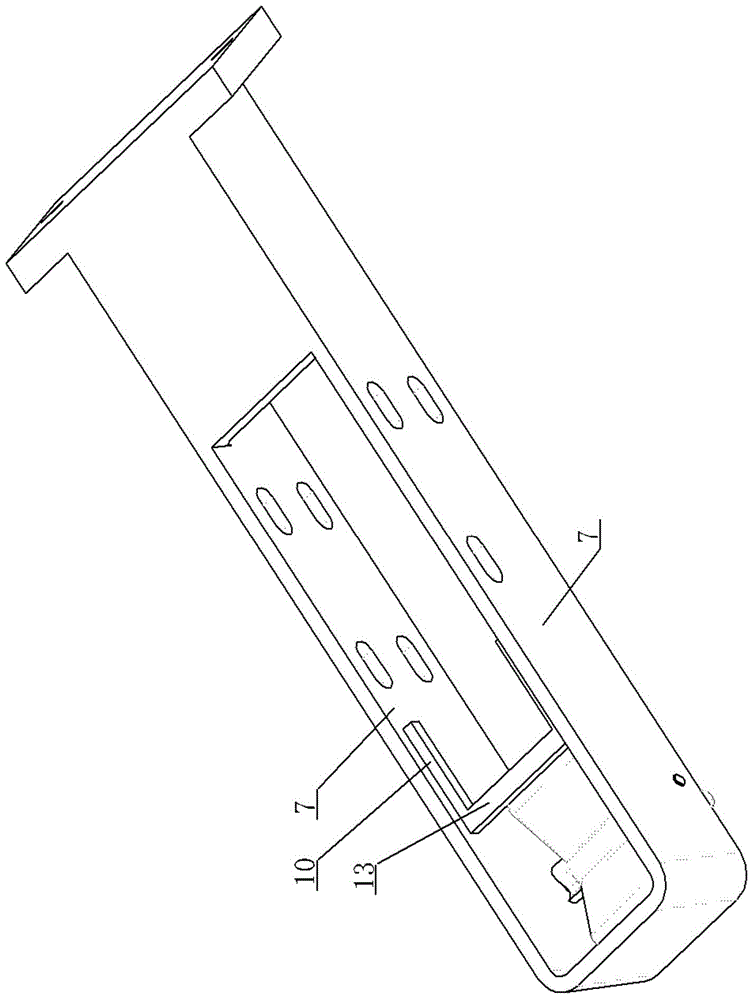

specific Embodiment 1

[0025] Specific embodiment one, see Figure 6 : the linear drive device 15 is specifically a push-pull electromagnet 16, the push rod 17 of the push-pull electromagnet 16 is exposed, the front end of the push rod 17 is fastened to the rear end connecting block 18 of the slider 11, and the stroke of the push rod 17 ensures that the pawl 14 and ratchet 9 are accurately loosened and locked, wherein the rear end of push rod 17 is tightly connected to moving iron core 19, and there is a gap between the moving iron core 19 and the static iron core 20 at the rear, and the front end of push rod 17 and A first return spring 21 is disposed between the front ends of the casing 20 . After receiving the instruction to deliver the medicine, the push-pull electromagnet 16 is energized, so that the push rod 17 is retracted, the pawl 14 and the ratchet 9 are separated, and the flap structure 4 pushes the boxed medicine 3 on the boxed medicine 3 by its own gravity. A baffle plate 6 turns over ...

specific Embodiment 2

[0026] Specific embodiment two, see Figure 7 : the linear drive device 15 can be an electromagnet 22, a second return spring 23, an iron core 25 is inserted in the shell 24 of the electromagnet 22, and the front end of the iron core 25 faces the rear end connection block 18 of the slider 11, and the electromagnet 22 There is a distance between the front end of the iron core 25 and the rear connecting block 18 in the non-energized state, and the second return spring 23 is arranged between the front end surface of the casing 24 and the rear connecting block 18 . After receiving the medicine delivery instruction, the electromagnet 22 is energized, the iron core 25 is magnetically charged, the rear connecting block 18 is adsorbed, the slider 11 slides backward, the ratchet 14 and the ratchet 9 are separated, and the flap structure 4 The self-gravity of the medicine promotes the first baffle plate 6 on the flap structure 4 to turn over the flap structure 4, so that the first box o...

specific Embodiment 3

[0027] Specific embodiment three, see Figure 8 : the linear drive device 15 can be a linear cylinder 26, the linear cylinder 26 is horizontally arranged in the fixed frame 1, the cylinder arm 8 of the linear cylinder 26 is fastened to the rear end connecting block 18 connected to the slide block 11, and the cylinder arm 8 in the initial state is in an extended state. In the long state, the ratchet 14 on the slider 11 locks the ratchet 9 on the flap structure 4. After receiving the instruction to deliver medicine, the cylinder arm 27 of the linear cylinder 26 shrinks rapidly, so that the ratchet 14 and the ratchet 9 are separated. The flap structure 4 pushes the first baffle plate 6 on the flap structure 4 under the self gravity of the medicine to overturn the flap structure 4, so that the first box of boxed medicine 3 slides out. After the first box of boxed medicine 3 slides out , the cylinder arm 8 of the linear cylinder 26 quickly extends to push the slider 11 to reset, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com