Portable device for accurately repairing wavy abrasion of steel rail of subway curve

A wave-shaped, portable technology, applied in the field of rail grinding, can solve the problems of high number of passes, high price, grinding, etc., and achieve the effect of reducing operating costs, increasing operating costs, and high grinding accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

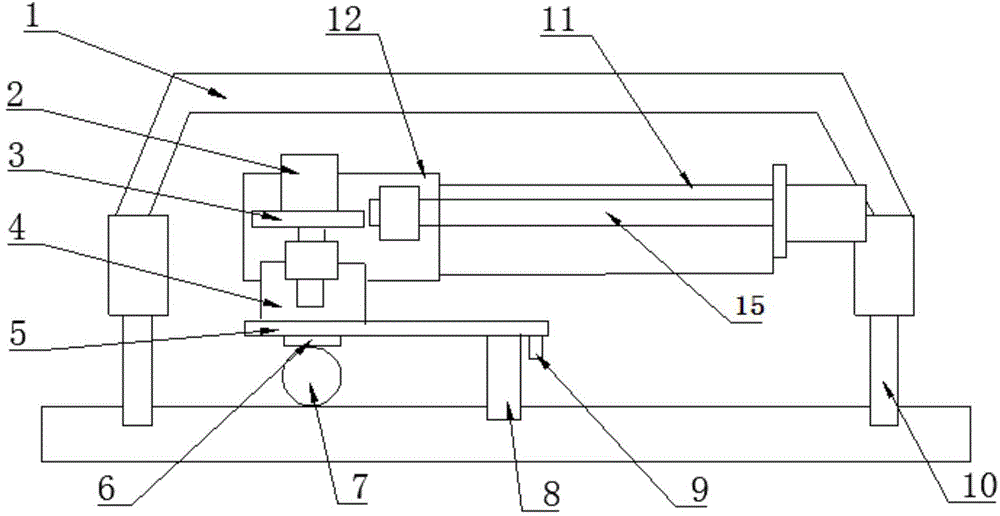

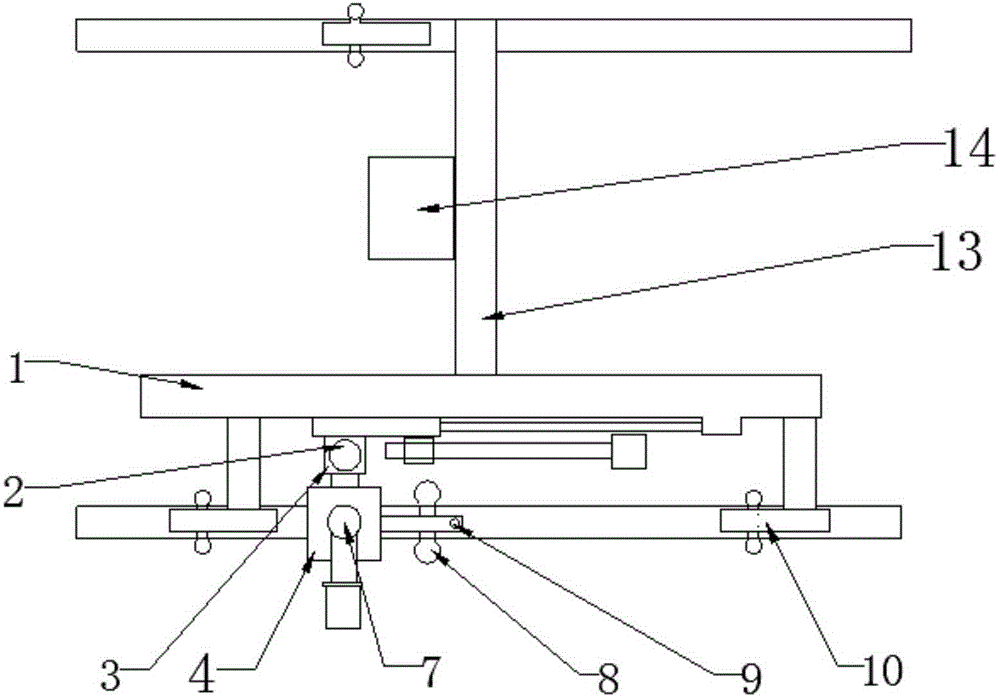

[0029] Such as Figure 1~2 As shown, a portable device for accurately repairing the wavy wear of subway curved rails, the device includes a laser ranging sensor 9 for detecting wavy wear of subway curved rails and a grinding assembly 7 for repairing, and also includes a driving grinder The cutting assembly 7 is a drive assembly and a control assembly that move in the X-axis direction, the Y-axis direction, and the Z-axis direction, and a detachable frame for installing the various components of the device;

[0030] The drive assembly includes an X-axis drive assembly, a Y-axis drive assembly and a Z-axis drive assembly, wherein:

[0031] The X-axis drive assembly includes an X-axis direction screw and a motor 15, an X-axis direction slide rail 11, and an X-axis direction slide block 12. The X-axis direction slide rail 11 is installed on the frame, and the X-axis direction Slider 12 is arranged on the X-axis direction slide rail 11, and described X-axis direction screw rod and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com