Hydrostatic travel drive for all-wheel drive working machines

A driving device and all-wheel drive technology, which is applied to the transmission device, fluid transmission device, transmission device control, etc., can solve the problems of increased installation costs, and achieve the effects of simple construction, low power loss, and high driving comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

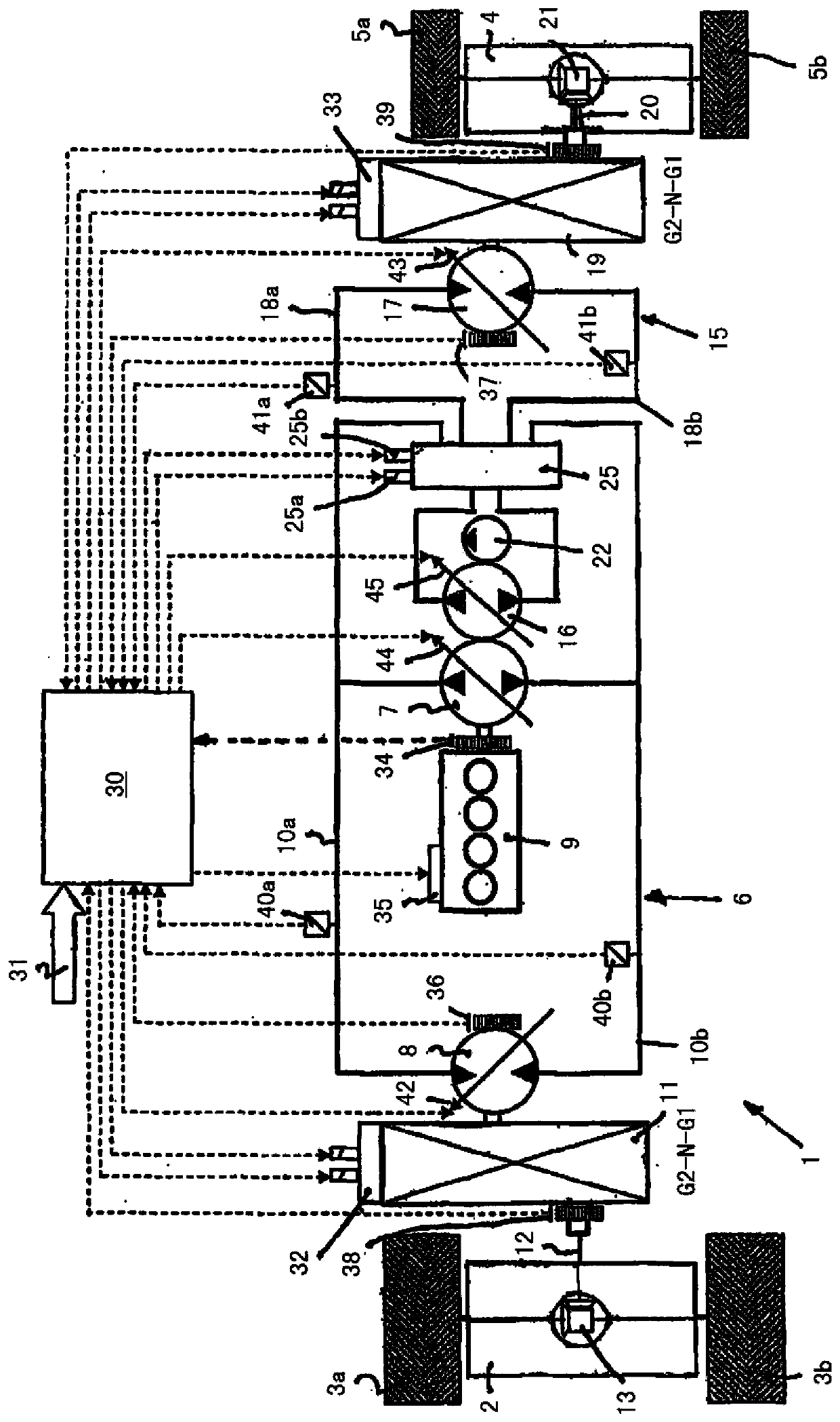

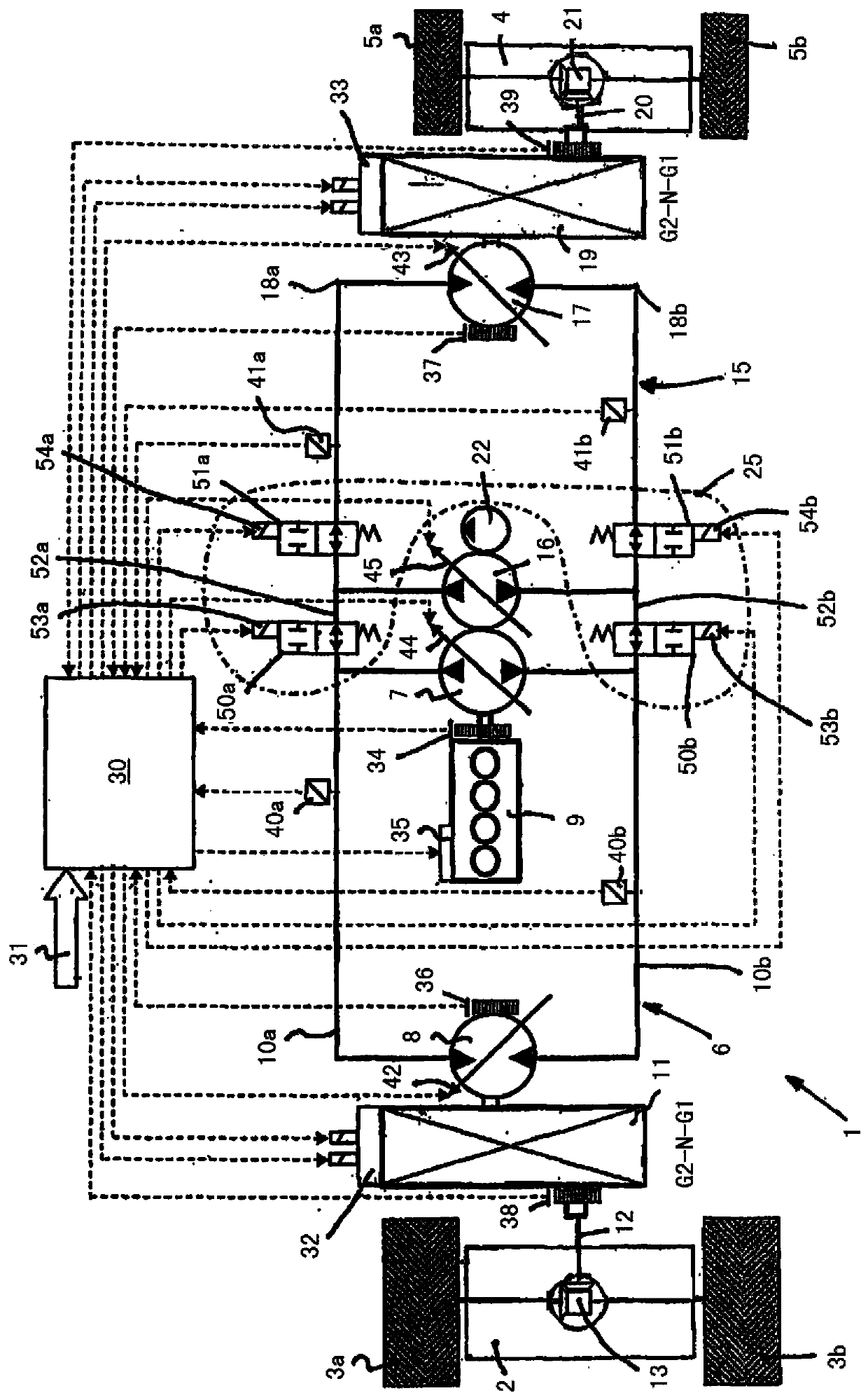

[0030] exist figure 1 A connection diagram of a hydrostatic traction drive 1 according to the invention of an all-wheel drive working machine, for example an agricultural harvester, is shown in .

[0031] The all-wheel drive working machine comprises a drive axle 2, eg a front axle, with driven wheels 3a, 3b, and a second drive axle 4, eg a rear axle, with driven wheels 5a, 5b. In this case, the drive axle 4 can be designed as a steerable axle with steerable wheels 5a, 5b. The wheels 3a, 3b or 5a, 5b can be configured as driven front and rear tires. Alternatively, the driven wheels 3 a , 3 b or 5 a , 5 b can be designed as crawler tracks, the running devices of which correspond to the driven wheels 3 a , 3 b or 5 a , 5 b.

[0032] The traction drive 1 includes, for the first drive axle 2 , a hydrostatic transmission 6 with a hydraulic pump 7 adjustable in delivery volume and a first hydraulic motor 8 coupled to the hydraulic pump 7 . The hydraulic pump 7 is connected for d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com