High performance pulse valve

A pulse valve and pulse technology, applied in the field of pulse valve, can solve problems such as valve pressure loss, and achieve the effect of improving reliability and performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

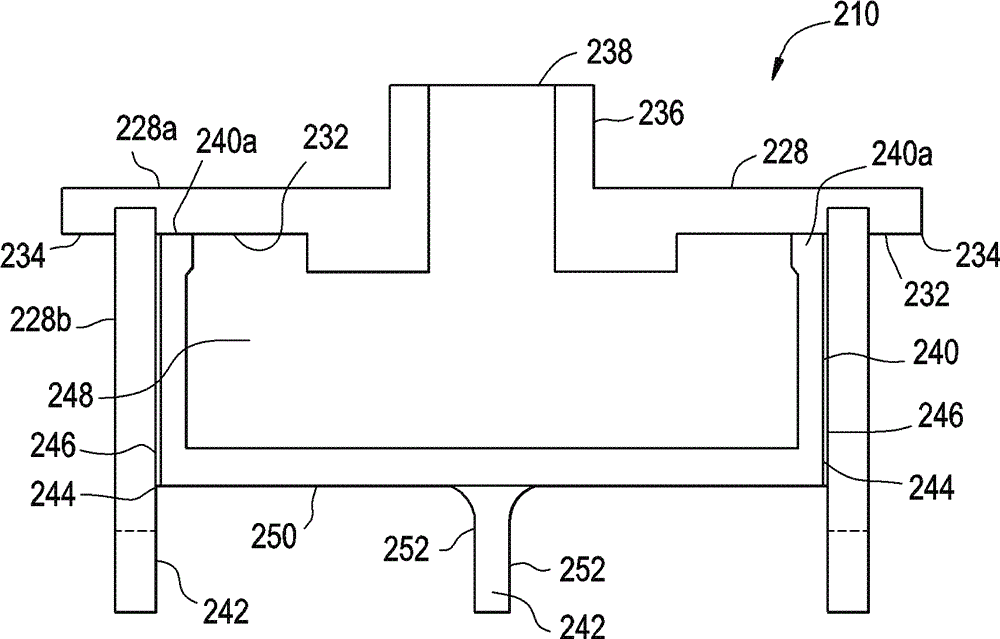

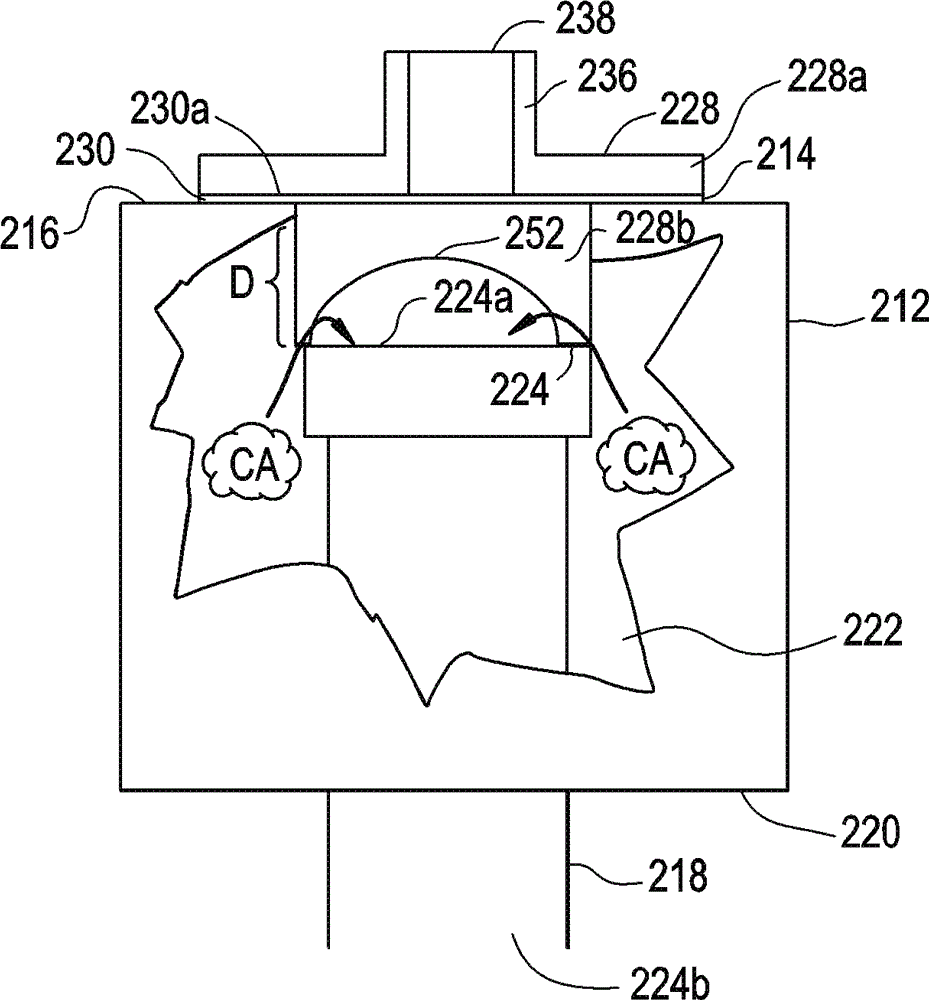

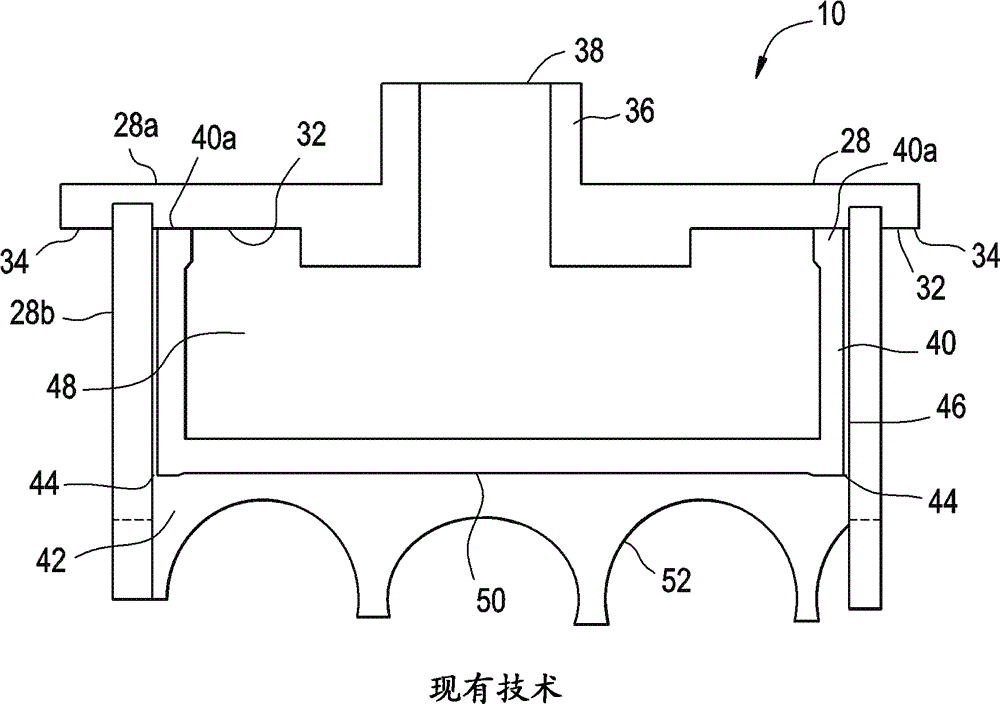

[0011] figure 1 with figure 2 The prior art valve arrangement 10 shown in is used to pulse compressed air "CA" to a vertically arranged bag filter element (not shown) in a filtering device for cleaning contaminated gas. The valve arrangement 10 is installed in the pressure medium tank 12 via a circular opening 14 provided in the upper wall 16 of the tank 12. The tank 12 is a compressed air tank.

[0012] A vertical pressure tube 18 coaxial with the opening 14 extends through the lower wall 20 and into the inner region 22 of the tank 12. The upper end 24 of the pressure tube 18 is arranged a distance “D” below the opening 14. The upper end 24 of the pressure tube 18 forms a valve seat 24a, and the lower end 24b of the pressure tube 18 opens outside the tank 12 to be fluidly connected to an opening in a bag-shaped filter element (not shown).

[0013] The valve arrangement 10 has a valve housing 28 composed of two circular coaxial parts, namely an upper part 28a and a tubular lower...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com