Oil baffle device for side face sleeve transformer

A technology for transformers and bushings, which is applied in the field of fire prevention and protection of side bushing transformer oil retaining devices, which can solve problems such as transformer fire spread, transformer high-voltage bushing explosion, air pollution, etc., to reduce air pollution, reduce water pollution, reduce The effect of extinguishing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The side bushing transformer oil retaining device according to the present invention will be further described below in conjunction with the accompanying drawings.

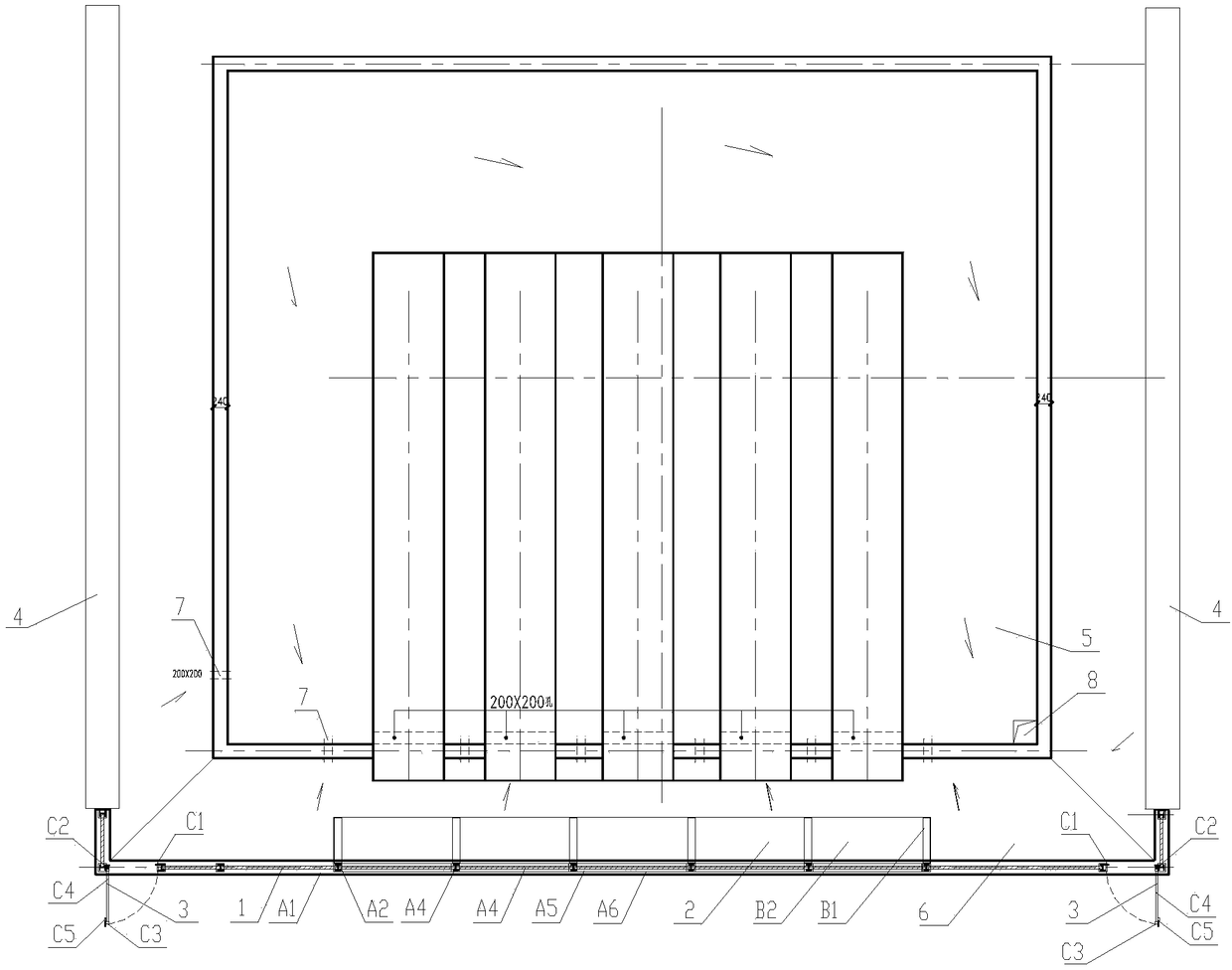

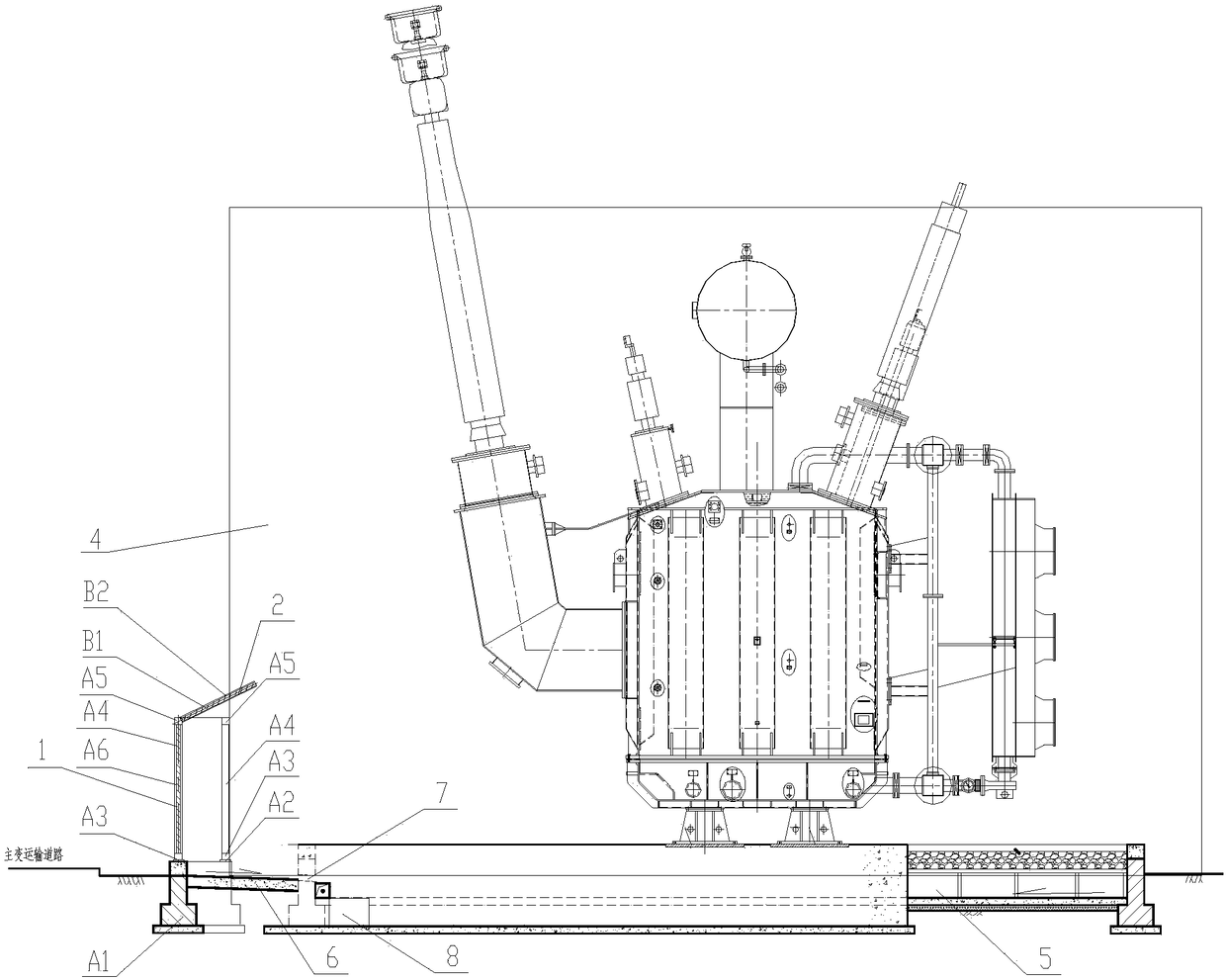

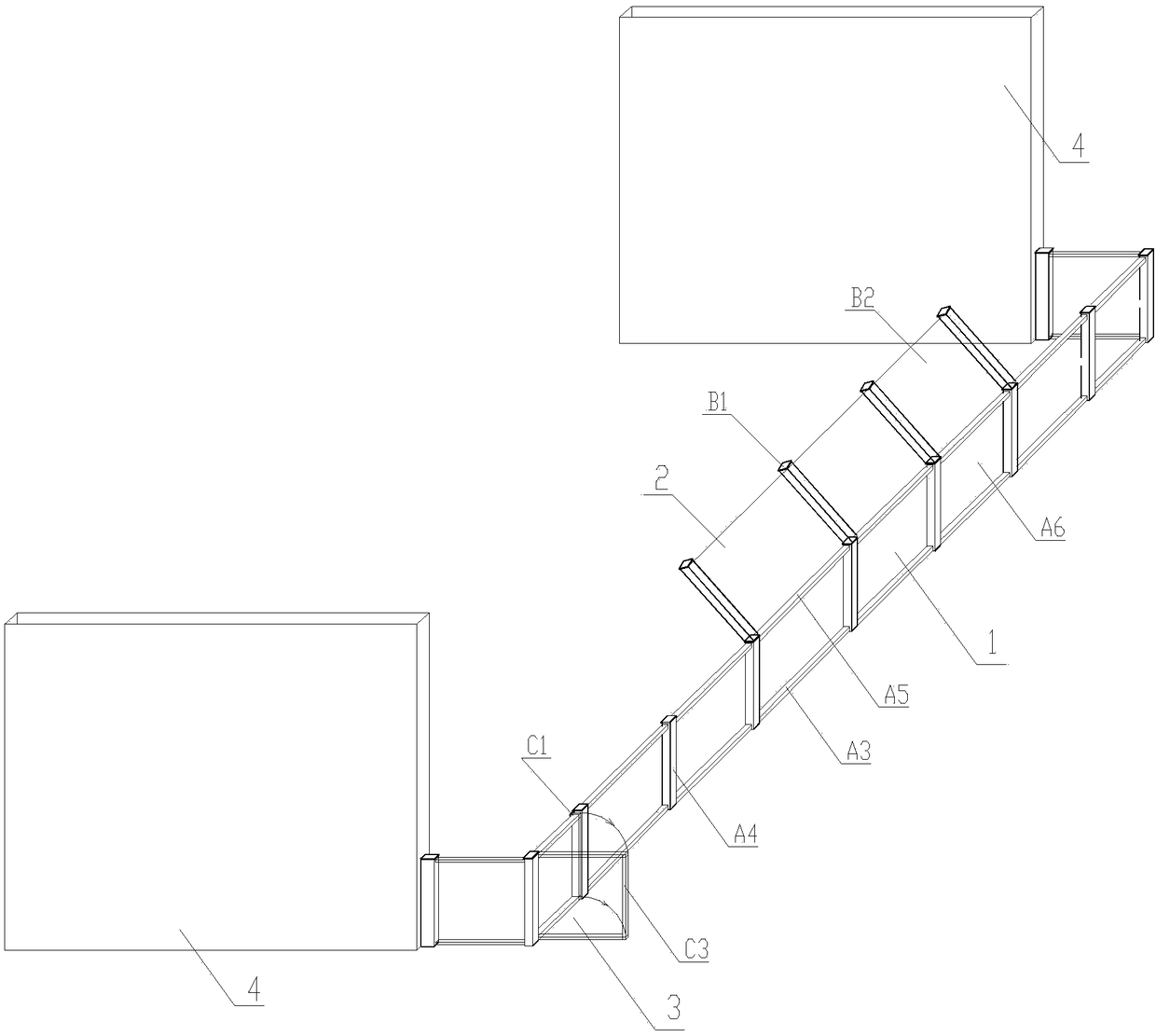

[0017] See figure 1 , a side bushing transformer oil retaining device, the device is installed on one side of the transformer with a side high voltage bushing, and is set about 1.5-2.5m away from the edge of the side bushing; the vertical movable fireproof oil retaining plate 1 relies on the built transformer firewall , or the newly-built transformer explosion fire protection wall 4 is set; the inclined movable fireproof oil baffle plate 2 is set on both sides of the side bushing within a range greater than 2m; the movable patrol door 3 is set on the patrol trail or fire trail on both sides of the transformer; The protective wall 4 is set on both sides of independent or adjacent transformers, the length of the protective wall is consistent with the requirements for the height of the transformer firewall, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com