Thermal insulation construction method in hot gas pipelines

A construction method and hot gas technology, applied in the field of metallurgical heat pipelines, can solve problems such as difficult construction, large construction volume, and long construction time, and achieve the effects of reducing construction technical difficulty, improving service life, and shortening construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0054] Take the 1# heating furnace hot air pipeline of Line 1549 as an example: the construction pipeline is ¢1520×8, and the length is 85 meters. Specifically, 40,035 Y-shaped anchor hooks, 2.65 tons of fiberboard, and 48 tons of fiber castable are required; the specific steps include the following:

[0055] (1) Production of spare parts and preparation of materials:

[0056] 1. According to the design of the heat insulation layer structure in the hot gas conveying pipeline after the improvement of the heating furnace, spare parts need to be produced: Y-type anchor hook, fiberboard, fiber castable;

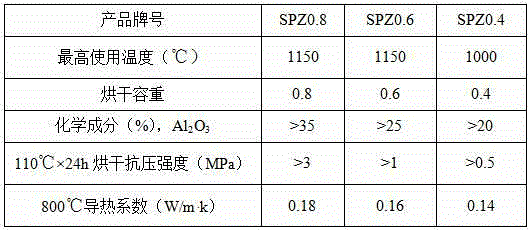

[0057] The fiber castable is a new type of refractory fiber castable low-temperature LT-J product, and the refractory fiber needle-punched blanket authorized by Combustion Engineering Company is used as the raw material. Small fiber diameter, long fiber, high tensile strength, no binder, no additives;

[0058] 2. According to the heat insulation layer structure design of the imp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface smoothness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com