Coal drying and upgrading method

A drying and coal technology, which is applied in the direction of drying solid materials, heating to dry solid materials, drying, etc., can solve the problems that the separation effect is not as good as the wet method, the process is complicated, and the efficiency is low, so as to avoid coal slime water pollution, The effect of expanding the application range and compact system structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Embodiments of the present invention are further described below in conjunction with accompanying drawings:

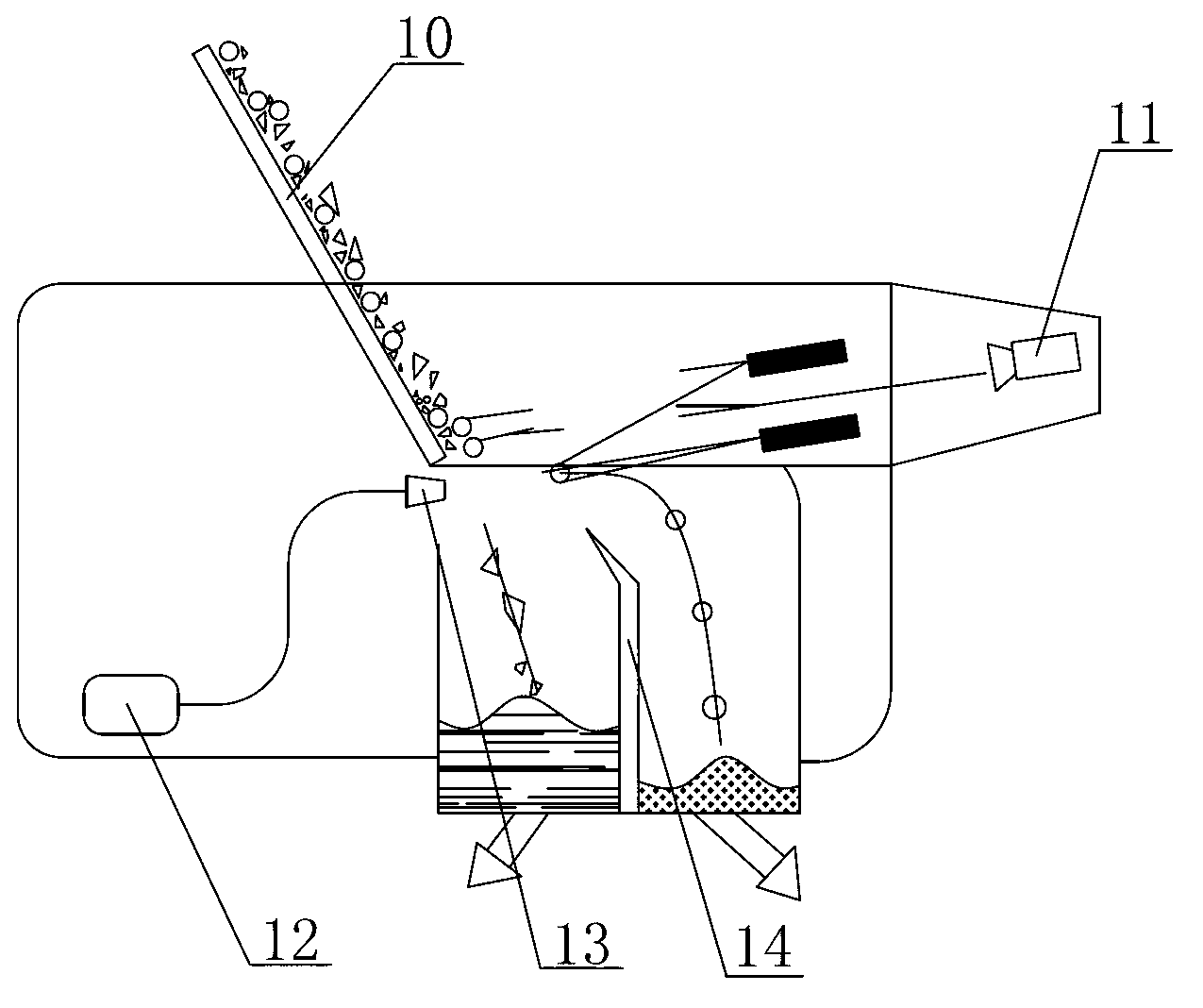

[0024] The method for drying and upgrading coal in the present invention mainly uses a microwave drying system to dry raw coal, and uses a sensor-based dry separation system to separate gangue or high-ash coal in the raw coal. The specific process is as follows:

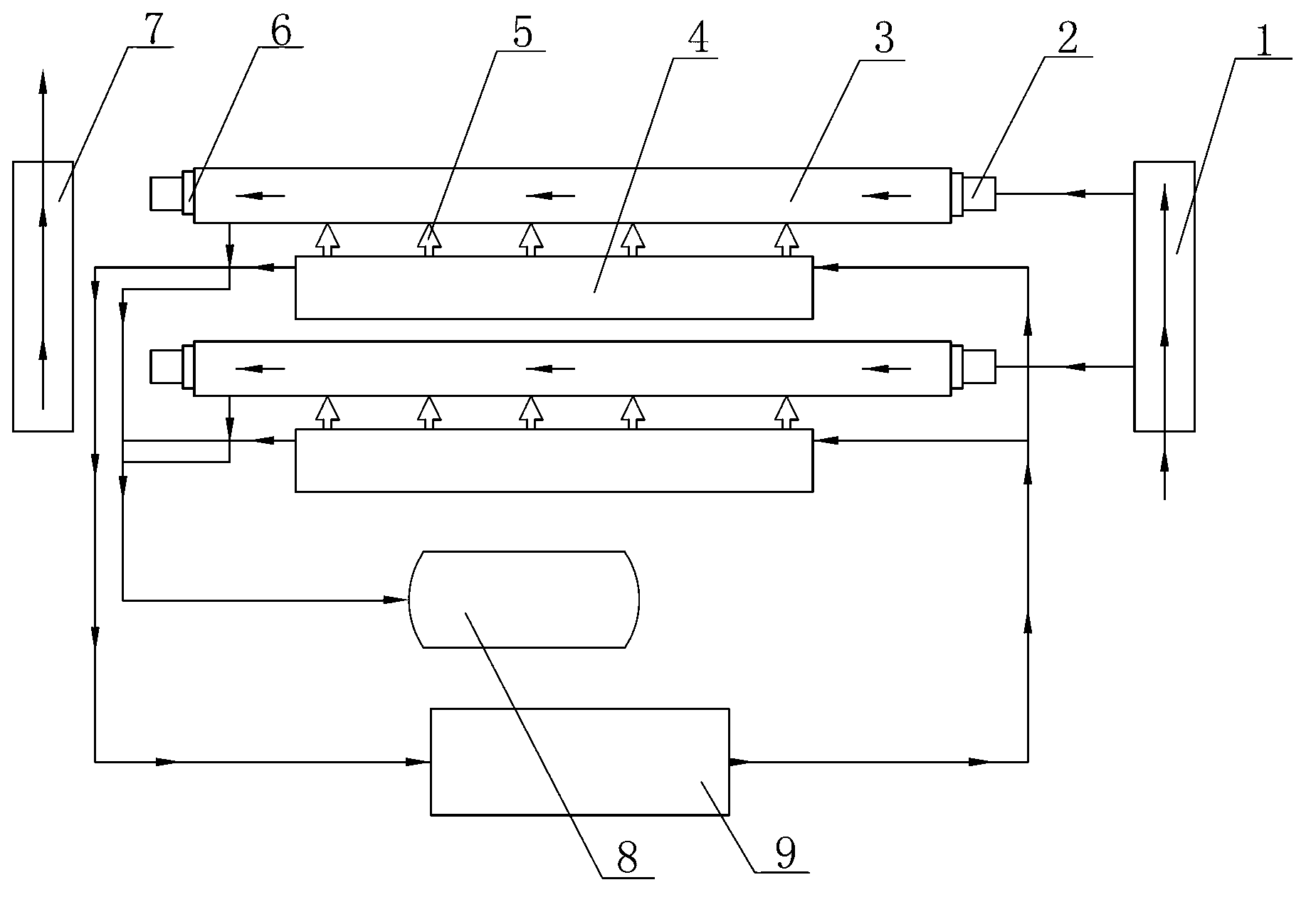

[0025] ① Dry raw coal with microwave drying system, such as figure 1 As shown, the raw coal enters the microwave drying system through the raw coal conveying device 1, and is loaded by the inner conveying device 2 (conveyor belt or other conveying device with the same function) that runs through the microwave oven body 3, and the microwave generator 4 connects with the microwave oven body 3 through the waveguide 5 Connected, the microwave is transmitted to the microwave oven body 3 through the waveguide 5 to dry the raw coal, and both ends of the inner conveying device 2 are provided with suppression c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com