Industrial nondestructive testing device

A non-destructive testing and equipment technology, applied in the direction of using radiation for material analysis, etc., can solve problems such as inability to perform three-dimensional imaging, limitations of applicable industries, and inability to view cross-sectional views, and achieve the effect of changing limitations, accurate image research, and improving adaptability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

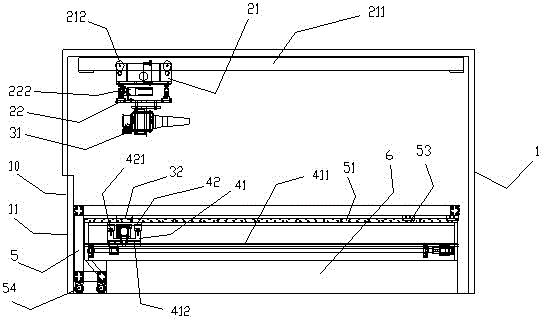

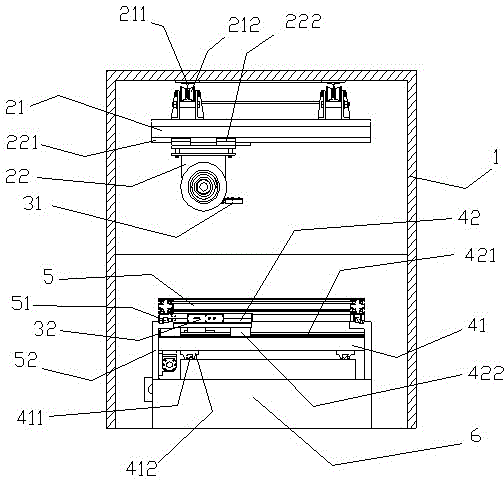

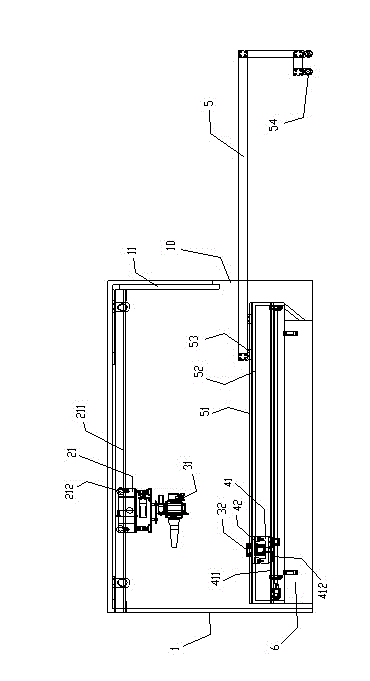

[0019] Such as figure 1 with figure 2 As shown, the embodiment of the present invention includes an X-ray machine 31 for emitting X-rays, a line array or flat panel detector 32 for receiving X-rays, and a set or accommodation for the X-ray machine 31, line array or flat panel detector 32 Operation of the protective lead room 1. In order to expand the scope of application and improve the imaging quality, this embodiment also includes a workbench 5 , a first platform 21 , a second platform 22 , a third platform 41 , a fourth platform 42 and a driving system.

[0020] The workbench 5 is located in the protective lead room 1 when the workpiece is detected, and is used to carry the workpiece, that is, the workpiece is positioned on the upper surface of the workbench 5 . The first platform 21 is movably arranged above the workbench 5 al...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com