Method capable of achieving internal storage local heating for high-temperature control test

A local heating and high temperature control technology, applied in the computer field, can solve the problem that the environment cannot reach the ideal temperature, and achieve the effects of convenient heating and temperature control, reasonable design, and simple and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

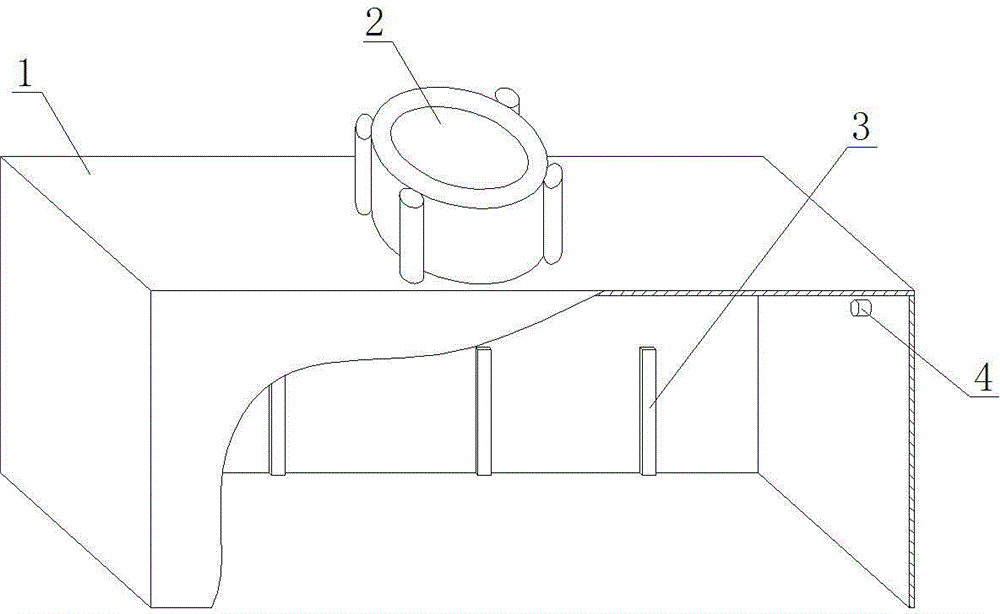

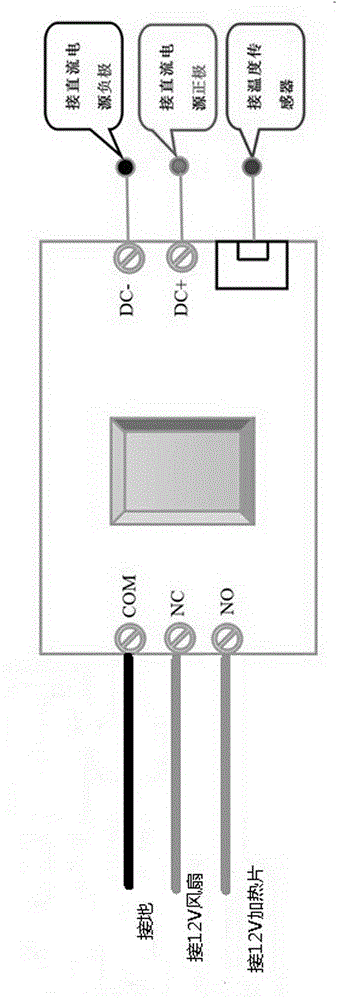

[0017] First, make a heat preservation cover for use. The structure of the heat preservation cover is as follows: the shell 1 of the heat preservation cover is in the shape of a rectangular hexahedron, made of high temperature resistant insulating plastic, with an open bottom and a circular through hole in the middle of the top. An exhaust fan 2 is installed at the circular through hole; two flexible heating sheets 3 are respectively installed on the inner wall on both sides of the inner cavity of the housing 1 , and a temperature sensor 4 is installed on the upper side of one end of the inner wall of the housing 1 . The exhaust fan 2 and the flexible heating sheet 3 are controlled by relays and digital tubes, the relays and digital tubes are installed on the main board and connected to the exhaust fan 2 and the flexible heating sheet 3 respectively through wires, and the power supply part is 12V DC, provided by the main board power supply.

[0018] The method steps are as foll...

Embodiment 2

[0021] First, make a heat preservation cover for use. The structure of the heat preservation cover is as follows: the shell 1 of the heat preservation cover is in the shape of a rectangular hexahedron, made of high temperature resistant insulating plastic, with an open bottom and a circular through hole in the middle of the top. An exhaust fan 2 is installed at the circular through hole; five flexible heating sheets 3 are respectively installed on the inner wall on both sides of the inner cavity of the housing 1 , and a temperature sensor 4 is installed on the upper side of one end of the inner wall of the housing 1 . The exhaust fan 2 and the flexible heating sheet 3 are controlled by relays and digital tubes, the relays and digital tubes are installed on the main board and connected to the exhaust fan 2 and the flexible heating sheet 3 respectively through wires, and the power supply part is 12V DC, provided by the main board power supply.

[0022] The method steps are as fol...

Embodiment 3

[0025] First, make a heat preservation cover for use. The structure of the heat preservation cover is as follows: the shell 1 of the heat preservation cover is in the shape of a rectangular hexahedron, made of high temperature resistant insulating plastic, with an open bottom and a circular through hole in the middle of the top. A 3cm*3cm exhaust fan 2 is installed at the circular through hole; three 20W flexible heating fins 3 are respectively installed on the inner walls of the inner chamber of the housing 1, and one end of the inner wall of the housing 1 is installed on the upper side temperature sensor4. The exhaust fan 2 and the flexible heating sheet 3 are controlled by relays and digital tubes, the relays and digital tubes are installed on the main board and connected to the exhaust fan 2 and the flexible heating sheet 3 respectively through wires, and the power supply part is 12V DC, provided by the main board power supply.

[0026] The method steps are as follows:

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com