Automatic taking-up and paying-off type stand cabinet soilless culturing system driven by linear motors

A technology of soilless cultivation and linear motor, which is applied in the direction of soilless cultivation, cultivation, botany equipment and methods, etc., to achieve the effect of fast speed, high efficiency and reduced space volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described below in conjunction with the accompanying drawings.

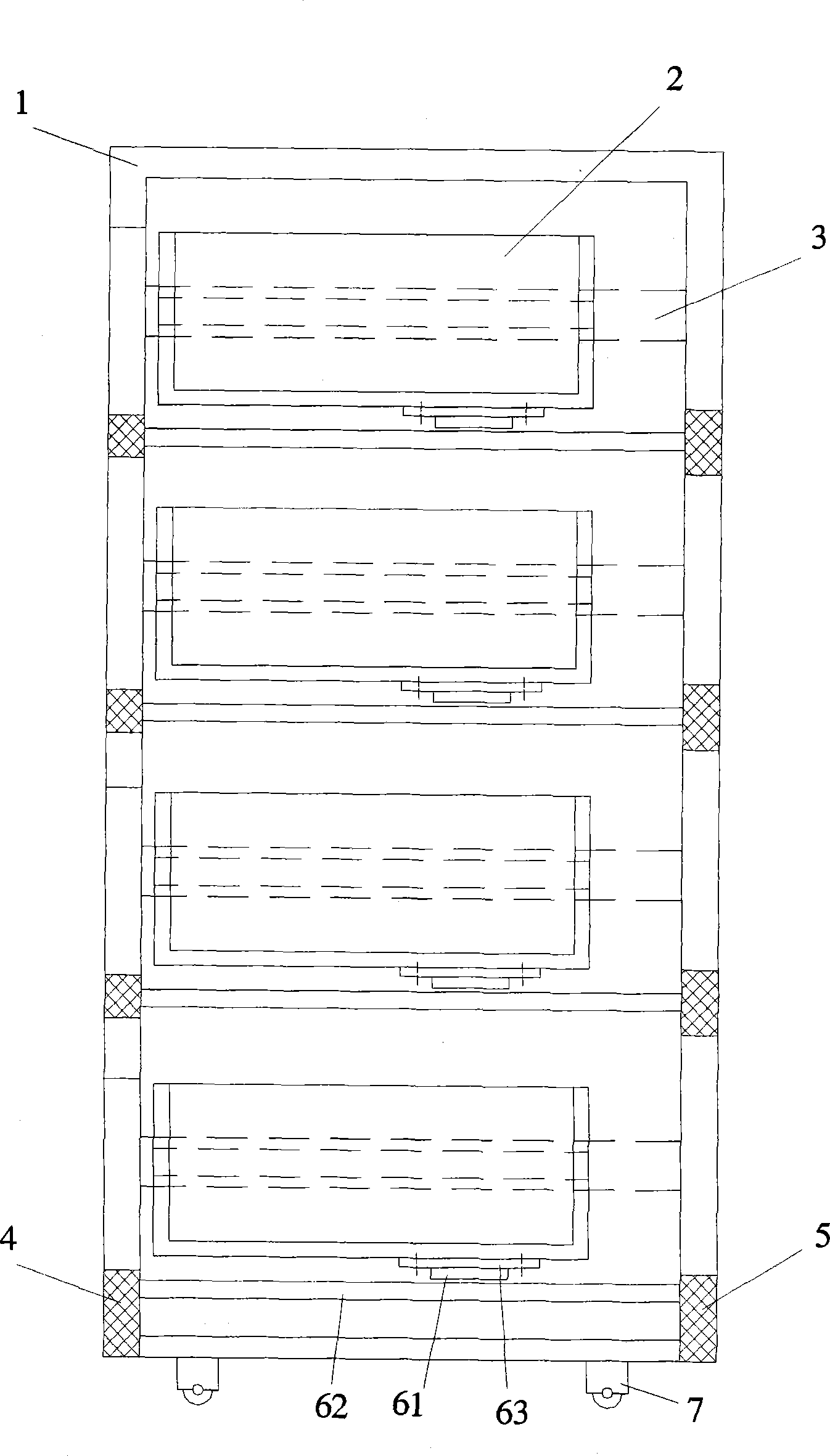

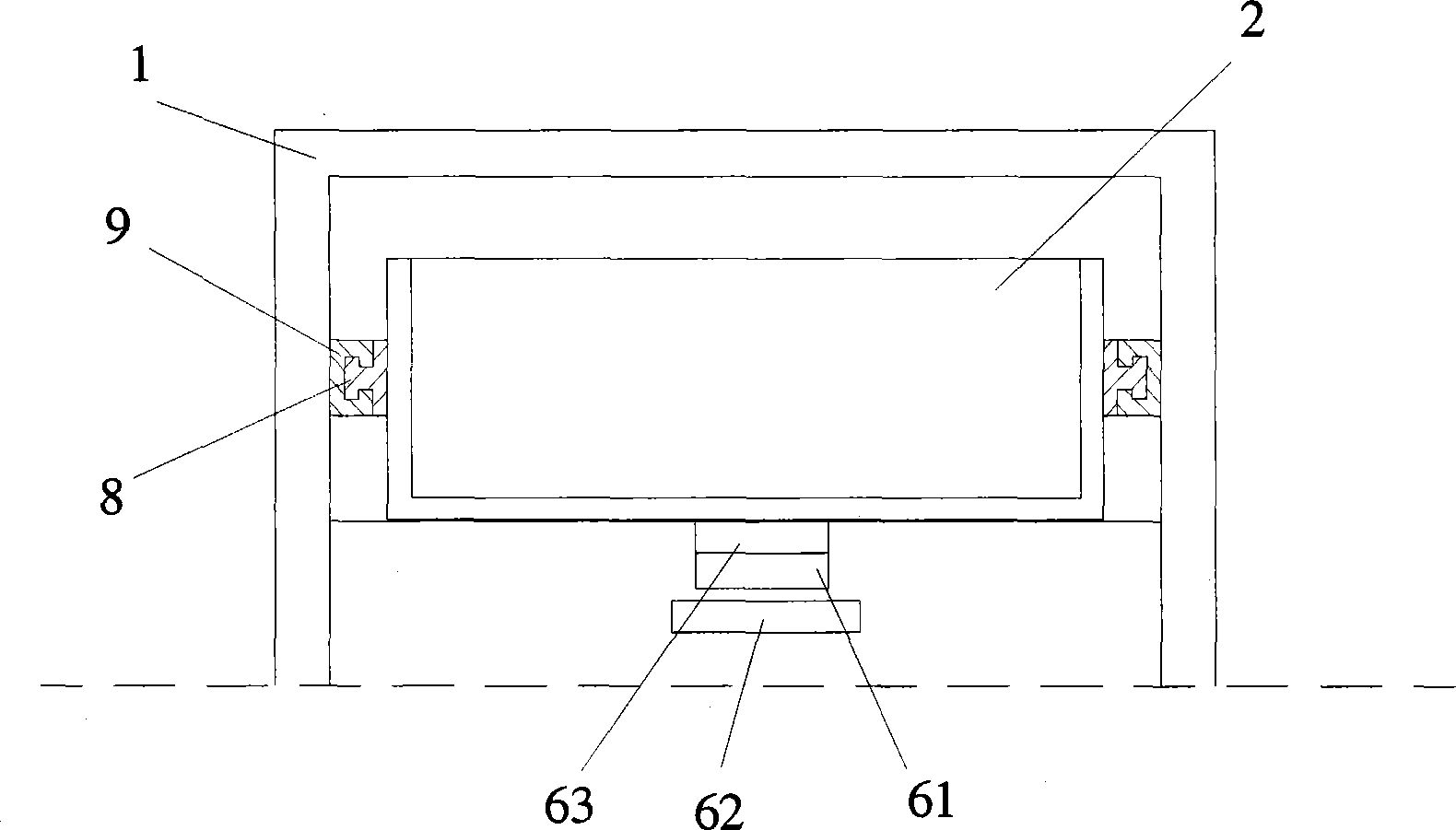

[0037] Such as figure 1 , 2 As shown, the soilless cultivation system of the present invention comprises a vertical cabinet body 1, and the cabinet body 1 includes a front beam 4 and a rear beam 5, and several drawer-type boxes 2 for soilless cultivation are arranged in the cabinet body 1, each drawer type The boxes 2 are stacked in the cabinet 1 .

[0038] As an embodiment, each box body 2 of the present invention can be arranged in a bracket with an upper end open, the box body 2 and the bracket are in a split structure, and the box body 2 can be freely taken and placed in the bracket. The bracket and the box body 2 jointly form a soilless cultivation unit.

[0039]A linear motor drive mechanism is provided below the box body 2, and the two ends of the stator 62 are respectively fixed on the front beam 4 and the rear beam 5 of the cabinet body 1, and the mover 61 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com