Vehicle frame longitudinal beam correcting device

A technology of a correction device and a longitudinal beam, which is applied in the field of automobile frame processing and maintenance devices, can solve the problems of inconvenient use and lack of flexibility, and achieve the effects of convenient movement, overcoming high labor intensity and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

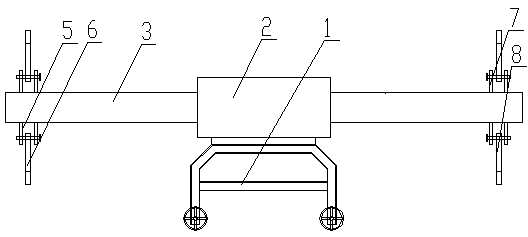

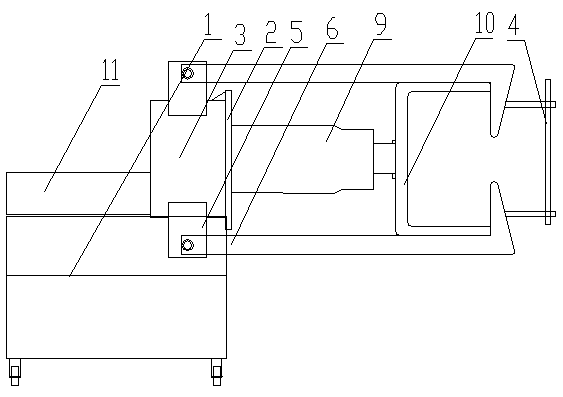

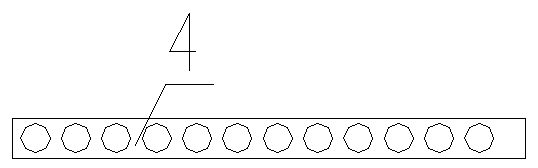

[0015] like Figure 1 to Figure 3 The frame longitudinal beam calibration device shown includes a frame 1 provided with casters; a calibration plate 2 welded on the first end of the frame 1; a pulling beam 3 welded with the frame 1 and the calibration plate 2; Anchor rod seats 5 and 7 (the other two are not marked) connected to the upper and lower sides of the two ends of the tension beam 3; Fixing pins at both ends; fixing blocks 4 for fixing the upper and lower anchor rods at the same end of the tension beam 3; movable hydraulic jacks 9; the fixing blocks 4 are provided with a plurality of through holes for the fixing pins to be inserted; A storage platform 11 is arranged between the pulling beam 3 and the second end of the frame 1, and the periphery of the storage platform 11 is provided with a fence; the anchor rods 6 and 8 (the other two are not marked) are L-shaped. The second end has a right-angled groove.

[0016] like figure 2 As shown, when calibrating the frame ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com