Heavy-load low-vibration all-dimensional wheel

An all-round wheel, low-vibration technology, applied in the direction of wheels, transportation and packaging, vehicle parts, etc., can solve the problems of limited application range, limitation of the overall bearing capacity of all-round wheels, large vibration, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

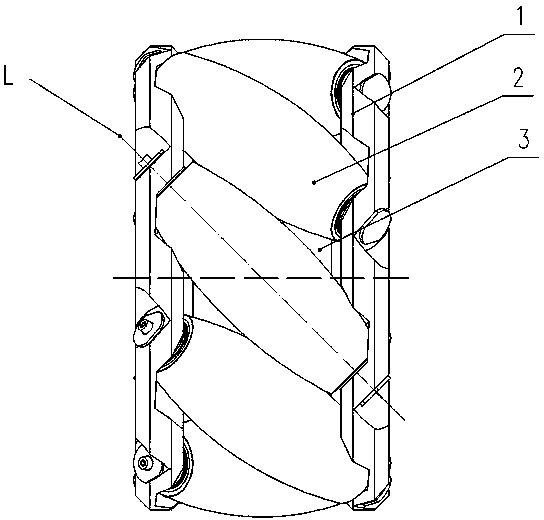

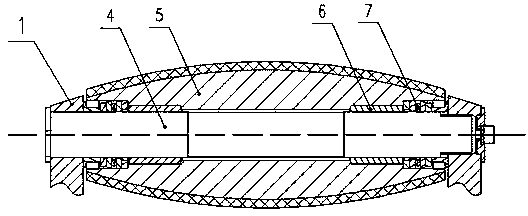

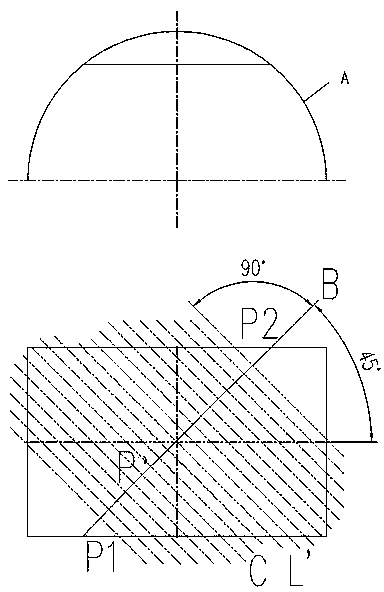

[0011] The specific implementation manner of the present invention will be described below with reference to the accompanying drawings. Such as Figure 1 to Figure 3 As shown: a heavy-duty low-vibration omni-directional wheel, which includes two hubs 1 fixedly connected by connecting sleeves 3, and eight rollers 2 that can rotate along their own axes are sandwiched between the two hubs 1, and All the rollers 2 are evenly distributed on the circumference of the hub 1, while the axis of the hub 1 and the axis L of the roller 2 form an included angle of 45°, and the plane perpendicular to the axis of the hub 1 is defined as the projection plane, the above eight The orthographic projection of the outer contour of the roller 2 on the projection plane forms a complete perfect circle D, and the roller 2 includes a roller body 5 and a roller shaft 4 nested in each other, and the distance between the roller shaft 4 and the roller body 5 Two sliding bearings 6 arranged symmetrically an...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap