Printing template containing rack

A technology for printing templates and racks, applied in the direction of external frames, transportation and packaging, packaging, etc., can solve the problems of inconvenient movement at any time, inconvenient access and placement of printing templates, etc., to achieve easy viewing and understanding, and conducive to drying , easy to place and use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

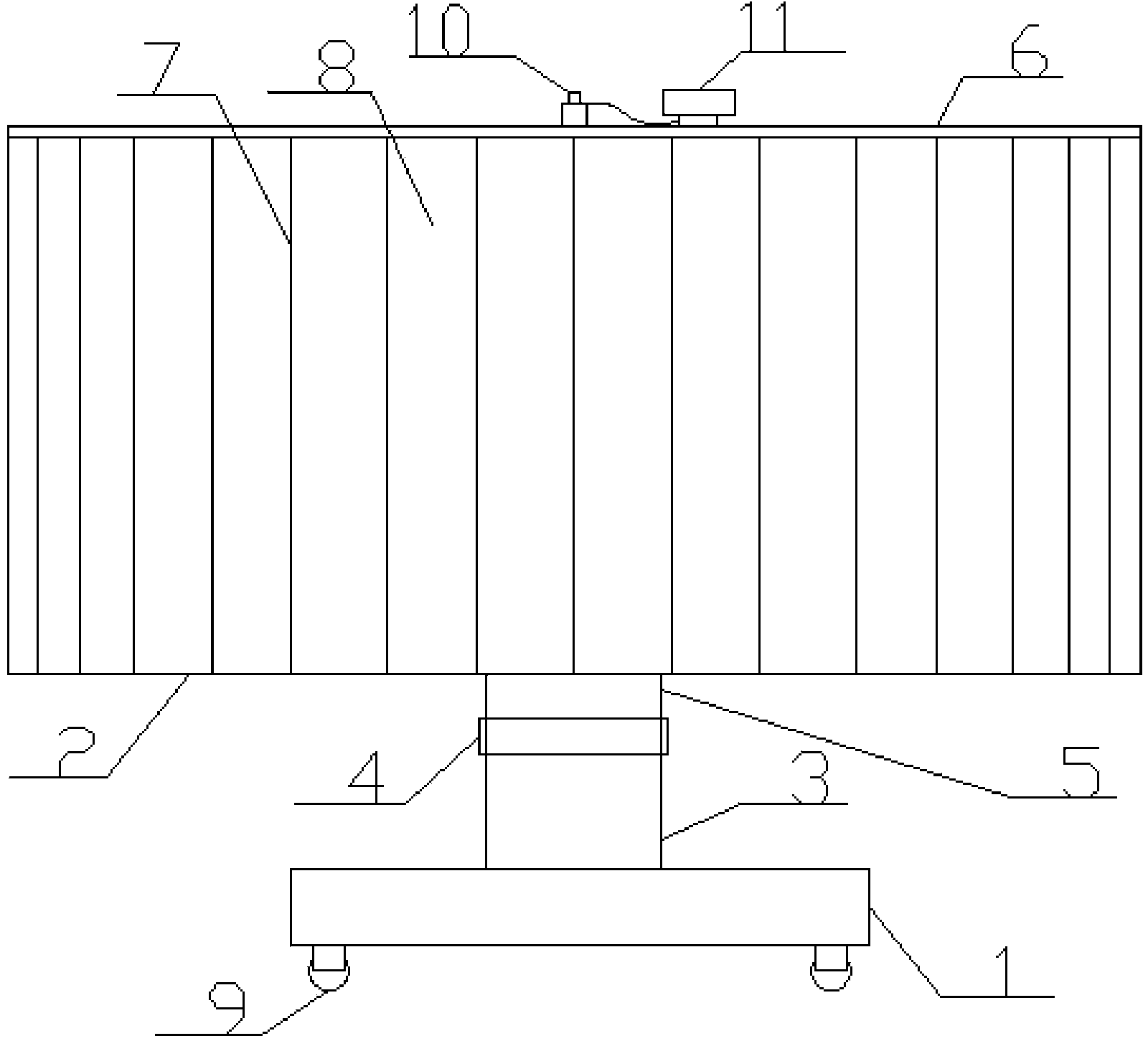

[0013] Such as figure 1 As shown, a printing template placement frame includes a base 1 and a frame 2, the base 1 is provided with a support column 3, the support column 3 is provided with a rotating shaft 4, and the rotating shaft 4 is connected to a connecting part 5, so The connecting portion 5 is fixedly connected with the frame 2, the frame 2 is cylindrical, the top of the frame 2 is provided with a cover plate 6, the inside of the frame 2 is provided with a fan-shaped partition 7, and the outer side of the partition 7 is An outlet 8 is provided, and the thickness of the cover plate 6 is 2 to 3mm. This kind of printing template placement frame, through this kind of structural design, people can place the printing template in the fan-shaped p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com