Coal blending expert system fit for top-loading coke oven

An expert system and coal blending technology, applied in coking ovens, petroleum industry, data processing applications, etc., can solve problems such as large prediction deviations of new coal types, deviations in coke predictions, coking time and coking temperature of coke ovens, etc. achieve low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

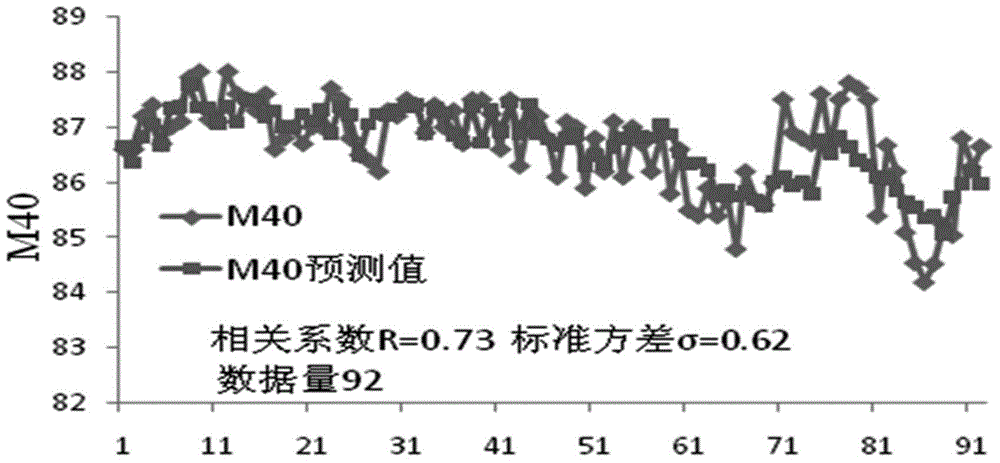

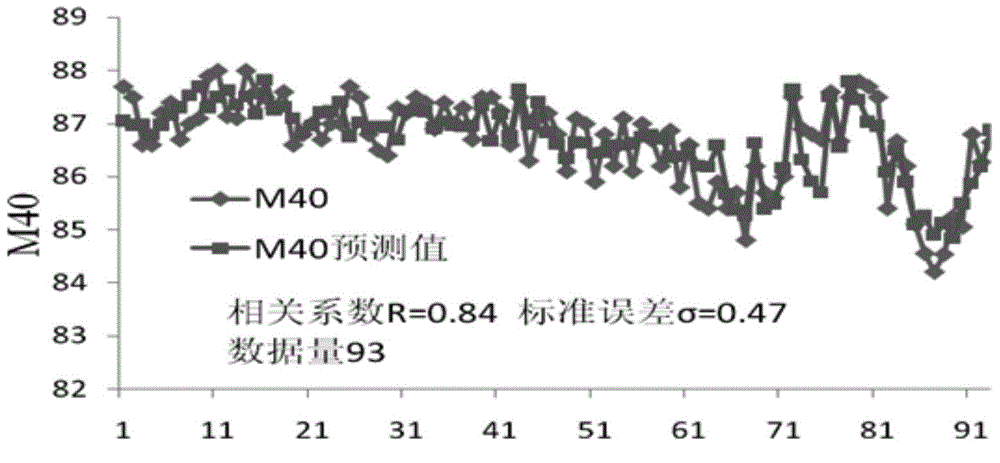

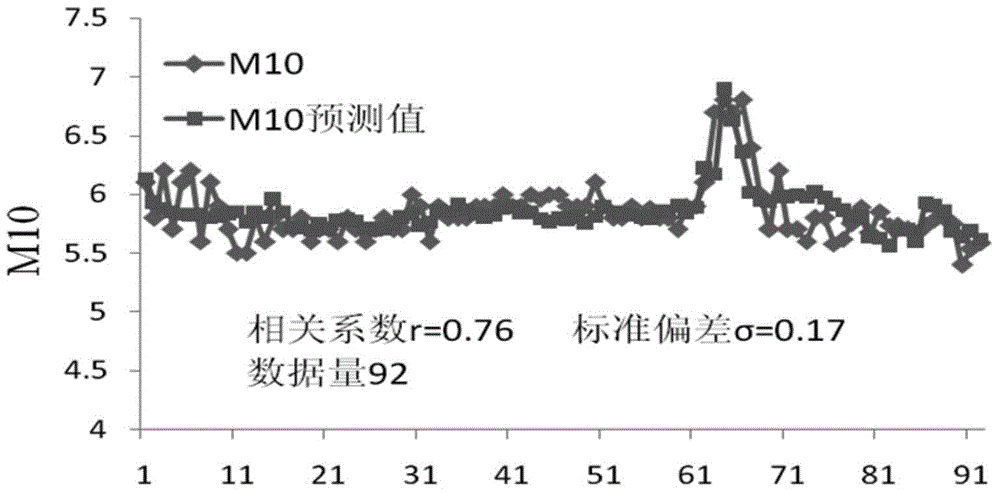

[0046] The embodiment of the present invention provides a new method. Coke quality prediction takes into account not only the coal quality index, but also coke oven operating parameters, coke quenching mode and other factors, and the coke quality is predicted by a nonlinear fitting method. Compared with the existing methods, the method is accurate and comprehensive, and the cost of coal blending can be greatly reduced through the systematic optimization of coal blending. Specifically, the following technical solutions are adopted:

[0047] (1) Realize the automatic data collection and correction of the quality inspection department and coal blending workshop, and establish a data collection system for coal and coal blending coking. Establish the interface connection between the quality management system, the coal blending production system and the coal blending system to realize the automatic collection of coal, coal blending and coke data. If there are data inconsistencies be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com