Sliding sleeve switch string and using method thereof

A sliding sleeve switch and pipe string technology, which is applied in the direction of mining fluid, earthwork drilling, cleaning equipment, etc., can solve the problem of poor cooperation between the switch tool lock block and the shoulder, reduce the reliability of the sliding sleeve switch tool string, and prevent scraping. cleanliness and other problems, to achieve the effect of alleviating downhole resistance, reducing the amount of use, and improving the firmness of the fit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with accompanying drawing.

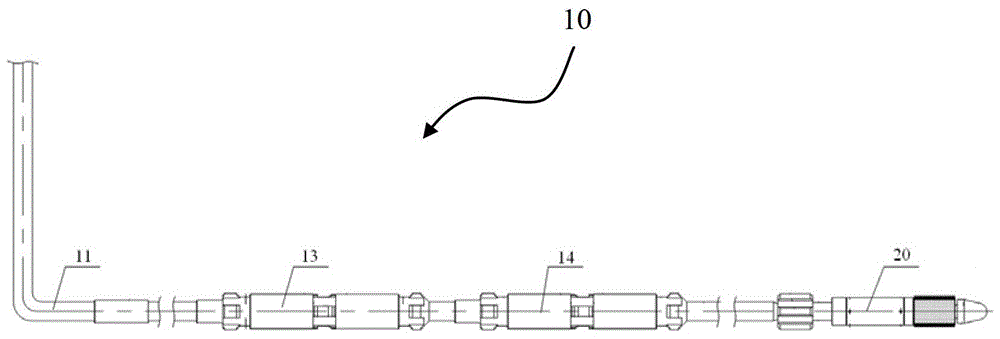

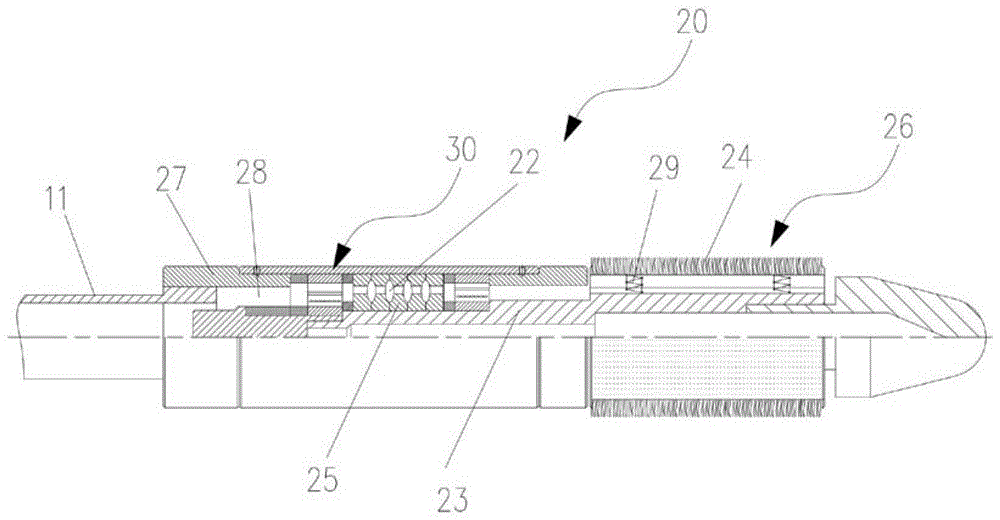

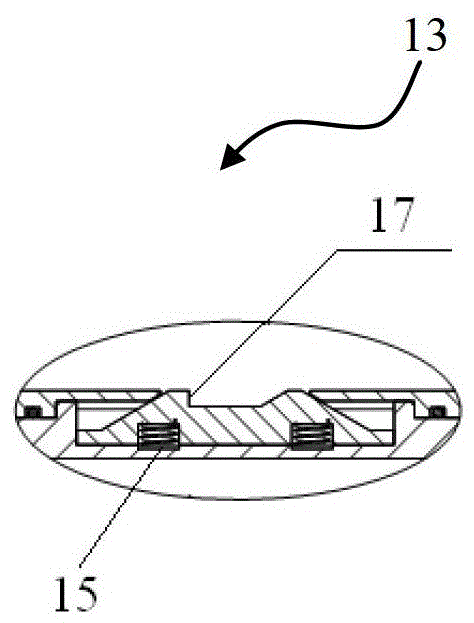

[0033] figure 1 A sliding sleeve switch string 10 according to the invention is schematically shown. The sliding sleeve switch string 10 includes a coiled oil tube 11 on which a pair of locking block tools 13 and 14 are arranged. The locking block tools 13 and 14 can protrude from the surface of the coiled tubing 11 so as to be used to open the sliding sleeve 39 (such as Figure 5 shown) and closing the sliding sleeve 39, for example, the locking block tool 13 is used to close the sliding sleeve 39, and the locking block tool 14 is used to open the sliding sleeve 39. exist figure 1 In the exemplary embodiment shown, the locking means 13 for closing the sliding sleeve 39 is arranged upstream of the locking means 14 for opening the sliding sleeve 39 . Inside the coiled tubing 11, a cleaning device 20 is provided downstream of the block tool. The cleaning device 20 includ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com