Novel displacement sensor transformation and amplification device

A displacement sensor and amplifying device technology, applied in the direction of measuring devices, instruments, etc., can solve the problems that the sensor cannot be placed, the displacement sensor is expensive, and the vertical rigidity is large, so as to achieve the effect of low cost, wide application range, and easy production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

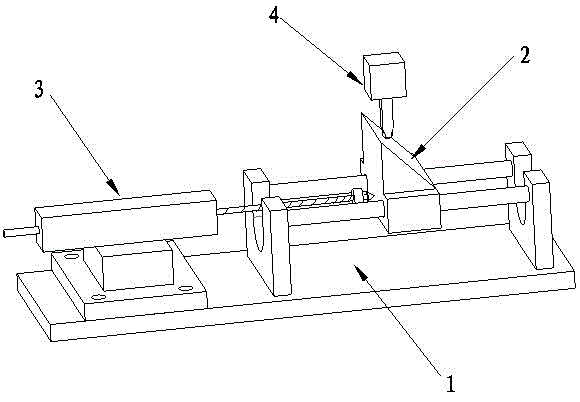

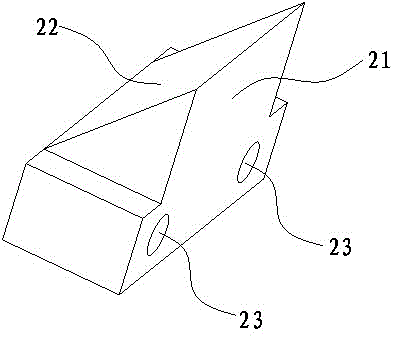

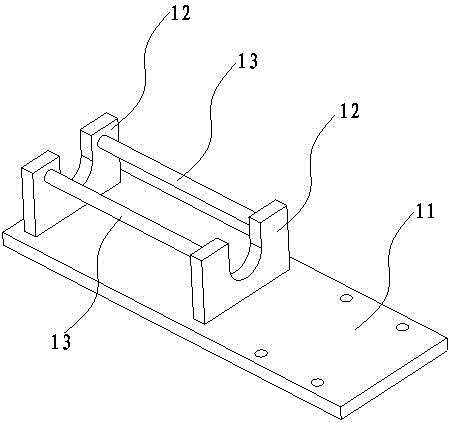

[0032] Such as Figure 1-5 As shown, the novel displacement sensor conversion and amplifying device of the present embodiment includes a base 1 on which a conversion slope 2 is slidably arranged, and a horizontal displacement meter 3 is also arranged on the base 1, and the horizontal displacement The meter 3 abuts against the vertical surface 21 of the conversion bevel body 2, and also includes a vertical pointer 4, and the vertical pointer 4 is slidingly connected with the slope 22 of the conversion bevel body 2, wherein the conversion bevel body The inclination angle of the inclined surface 22 of 2 and the horizontal plane is 45 °.

[0033] The novel displacement sensor conversion and amplifying device of the present embodiment only has the effect of displacement conversion. In the process of using, at first the device is placed between the upper base plate 5 and the lower base plate 6 of the test equipment, and the vertical pointer 4 The tail part is connected with the bot...

Embodiment 2

[0040] Such as Figure 6-7 As shown, the difference between this embodiment and Embodiment 1 is that: the inclination angle between the inclined surface 22 of the conversion inclined plane body 2 and the horizontal plane is less than 45°. The new displacement sensor conversion and amplification device of this embodiment has the functions of displacement conversion and displacement amplification. Its installation and operation process is the same as that of Embodiment 1. The vertical displacement of the test body will be amplified, and its amplification factor depends on the ratio of the maximum height of the bottom of the inclined plane to the vertical projection length of the inclined plane; The vertical pointer 4 of the amplifying device moves upward, and the probe 32 of the horizontal contact sensor is provided with a spring, and the spring will elongate at this time, thereby pushing the inclined-plane conversion body to move away from the horizontal displacement meter 3, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com