Method for determining grain protein

A method of determination and protein technology, which is applied in the field of determination of grain protein, can solve the problems of long time-consuming, cumbersome operation, large amount of digestion catalyst, etc., and achieve the effect of easy operation and accurate measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

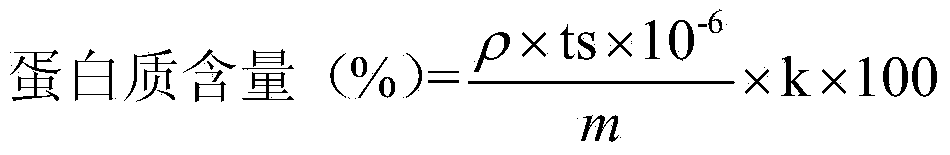

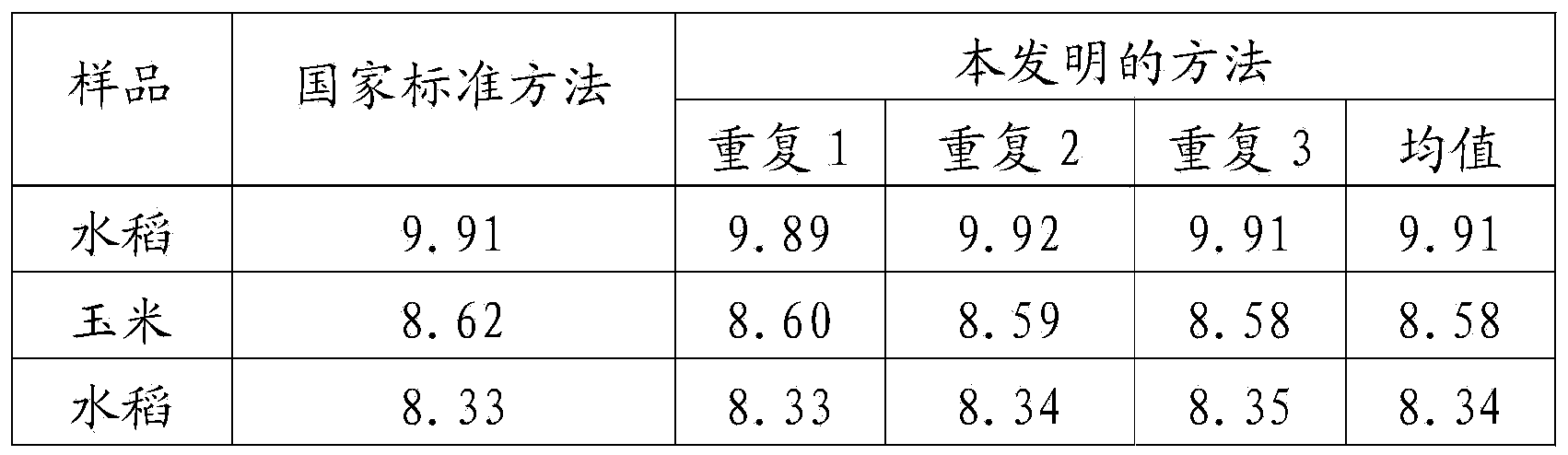

[0020] Embodiment 1: a kind of assay method of cereal protein

[0021] Weigh 0.1152g rice sample and place it in a 50ml digestion tube, add 5ml concentrated H 2 SO 4 , placed on a far-infrared digestion furnace, heated at 80-100 ° C, until concentrated H 2 SO 4 Decompose and emit white smoke and raise the temperature until the solution turns brown-black, remove the digestion tube from the digestion furnace, cool for 1 minute, add 300g / LH drop by drop 2 o 2 10 drops, shake well, heat on the digestion stove for 10 minutes, remove and cool for 1 minute, then add 300g / LH 2 o 2 10 drops, repeat this way 2-3 times until the cooking solution is colorless or clear, then heat for 10 minutes to remove excess H 2 o 2 , that is, the digestion is completed; transfer the digestion solution to a 100ml volumetric flask, and filter after constant volume; accurately draw 1ml of the filtrate into a 50ml colorimetric tube, add an appropriate amount of water, adjust it to neutral with NaOH ...

Embodiment 2

[0022] Embodiment 2: a kind of assay method of cereal protein

[0023] Weigh 0.1232g corn sample and place it in a 50ml chemical tube, add 5ml concentrated H 2 SO 4 , placed on a far-infrared digestion furnace, heated at 80-100 ° C, until concentrated H 2 SO 4 Decompose and emit white smoke and increase the temperature until the solution turns brown-black, remove the digestion tube from the digestion furnace, cool for 5 minutes, add 300g / L H 2 o 2 10 drops, shake well, heat on the digestion stove for 10 minutes, remove and cool for 5 minutes, then add 300g / L H 2 o 2 5 drops, repeat this way 2-3 times until the cooking solution is colorless or clear, then heat for 5 minutes to remove excess H 2 o 2 , that is, the digestion is completed; transfer the digestion solution to a 100ml volumetric flask, and filter after constant volume; accurately draw 1ml of the filtrate into a 50ml colorimetric tube, add an appropriate amount of water, adjust it to neutral with NaOH solution,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com