Tunnel cable fault inspection system and corresponding tunnel cable fault inspection method

A cable and fault technology, which is applied in the field of tunnel detection, can solve problems such as the inability to detect whether the damaged fixing fixture on the appearance of the cable has fallen off, and the inability to prevent the danger of the cable, etc., to achieve simple structure, ensure driving safety, and collect accurate results Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Embodiment 1 A tunnel cable fault inspection system and corresponding tunnel cable fault inspection method

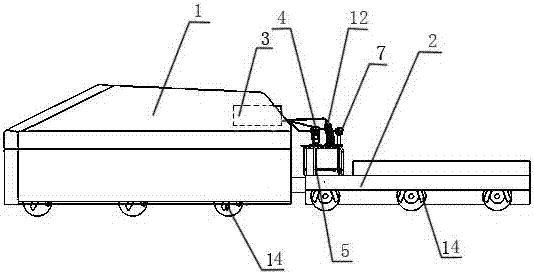

[0040] In this embodiment, the tunnel cable fault inspection system refers to figure 1 ,it includes:

[0041] (1) Automatically running inspection vehicle, in this embodiment, the railway fuel locomotive is used as the inspection vehicle, and the maximum speed can reach 80KM / h. like figure 1 As shown, the inspection vehicle includes a front 1 and a rear 2 , and wheels are provided on the lower surfaces of the front 1 and the rear 2 . In this embodiment, the front 1 is a carriage structure, and a control unit 3 wirelessly connected to the main control center of the control room is fixed inside; the rear 2 is a flat plate, which can be used as a mounting base for installing other components.

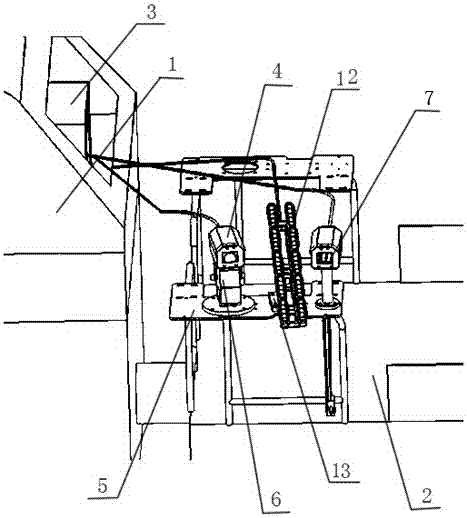

[0042] (2) An information collection unit that inspects the cables in the tunnel. The information collection unit in this embodiment is as follows figure 2 As shown, it...

Embodiment 2

[0068] Embodiment 2 A tunnel cable fault inspection system and corresponding tunnel cable fault inspection method

[0069] In this embodiment, the tunnel cable fault inspection system refers to figure 1 ,it includes:

[0070] (1) Automatically running inspection vehicle, in this embodiment, the railway fuel locomotive is used as the inspection vehicle, and the maximum speed can reach 80KM / h. like figure 1 As shown, the inspection vehicle includes a front 1 and a rear 2 , and wheels are provided on the lower surfaces of the front 1 and the rear 2 . In this embodiment, the front 1 is a carriage structure, and a control unit 3 wirelessly connected to the main control center of the control room is fixed inside; the rear 2 is a flat plate, which can be used as a mounting base for installing other components.

[0071] (2) An information collection unit that inspects the cables in the tunnel. The information collection unit in this embodiment is as follows figure 2 As shown, it...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com