A multi-angle arc light intensity collection method based on ccd camera

A collection method, arc light technology, applied in the direction of auxiliary welding equipment, welding equipment, manufacturing tools, etc., can solve the problems of arc instability, measurement result error, no guaranteed time resolution, etc., to achieve guaranteed time and space resolution, good time, and reduce the effect of high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

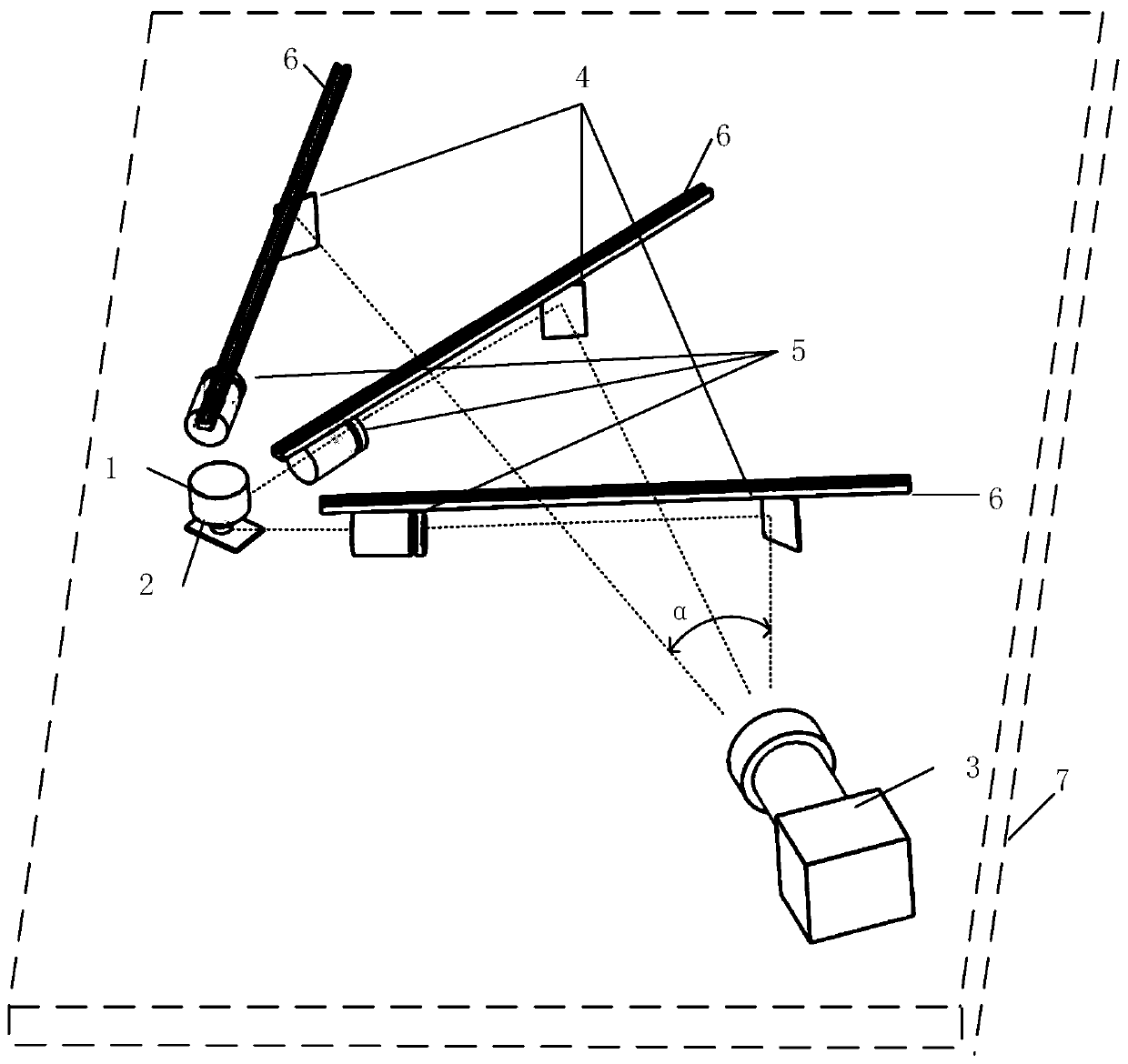

[0035] Such as figure 1 The embodiment of the present invention provides a multi-angle arc light intensity acquisition method based on a CCD camera, which includes the following steps when performing arc narrow-band spectral image acquisition:

[0036] Step S1: Fix the mirror group (4, 5) and the CCD camera (3) on the welding gun (1) through the connecting plate (7).

[0037] Step S2, adjust the height of the mirror group (4, 5) and the CCD camera (3), so that the lens axis of the mirror group (4, 5) and the arc CCD camera (3) are on the same plane.

[0038] Step S3, the slide rail (6) is placed in the direction of the observation angle with the arc (2) as the center, and the distance between the mirror group (4) and the arc (2) is adjusted on the slide rail (6) so that the two most mirrors The included angle α does not exceed the angle of view of the camera lens (3).

[0039] Step S4, the light emitted from the arc position passes through the relay lens (5), the reflector (4), the ne...

Embodiment 2

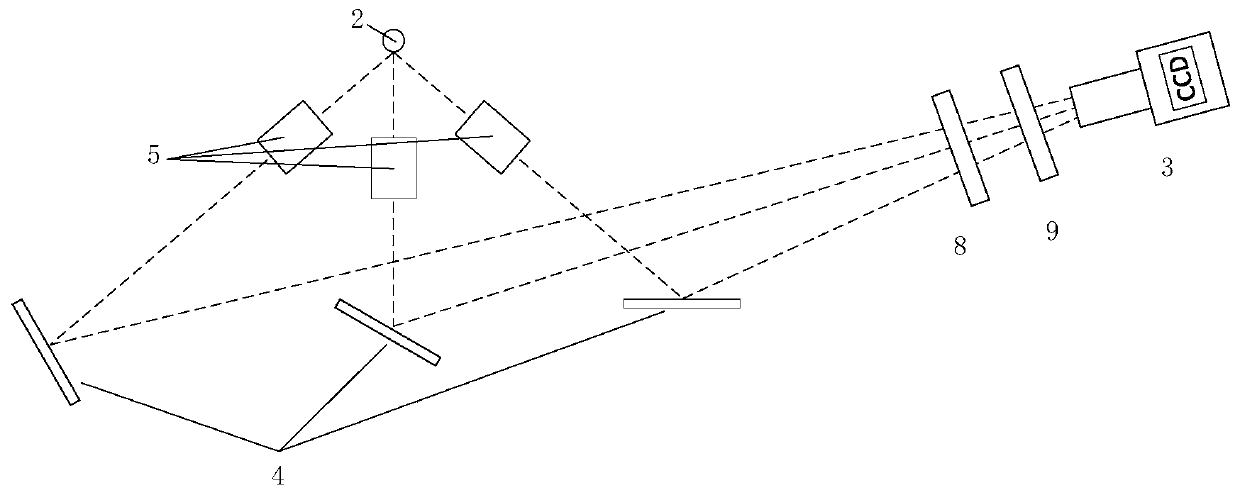

[0042] Such as figure 2 The embodiment of the present invention provides a multi-angle arc light intensity acquisition method based on a CCD camera. When the arc is directly observed, the narrow-band filter (9) in front of the camera (3) lens is removed, so that in each group of light paths, After the arc light from various angles is emitted from the arc (2), it passes through the relay lens (5), the reflector (4), and the neutral light-reducing film (8) in turn. The experimental procedure is the same as that in Example 1, and finally the arc appears in the camera Images from all angles.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com