Chain plate type baking tunnel furnace

A tunnel furnace and chain plate technology, which is applied in the fields of baking, food oven, food science, etc., can solve the problems of steel belt deviation, unfavorable production cost, troublesome users, etc., to ensure long-term stable operation and improve production Efficiency, the effect of avoiding stuck

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Below, in conjunction with accompanying drawing and specific embodiment, the present invention is described further:

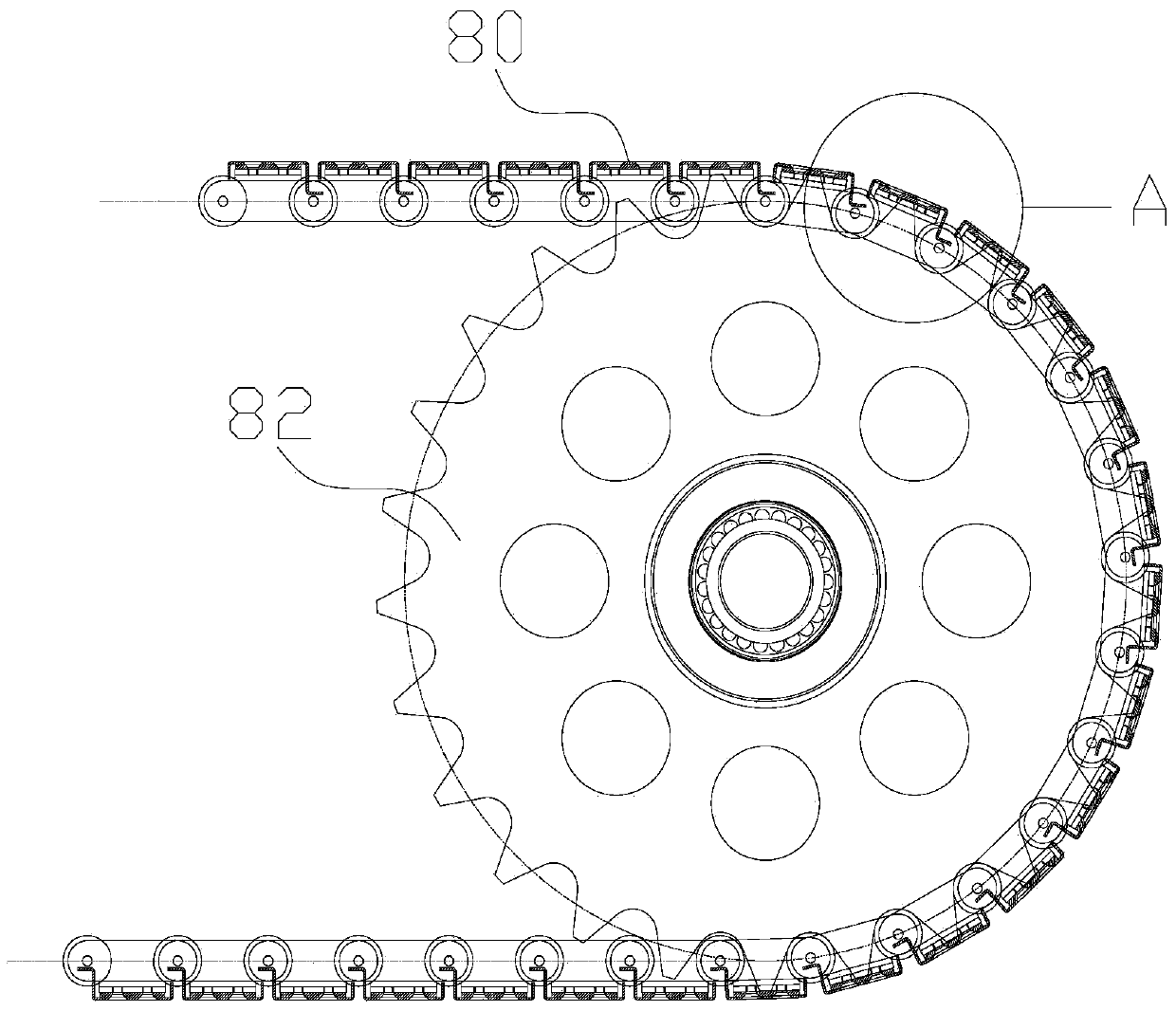

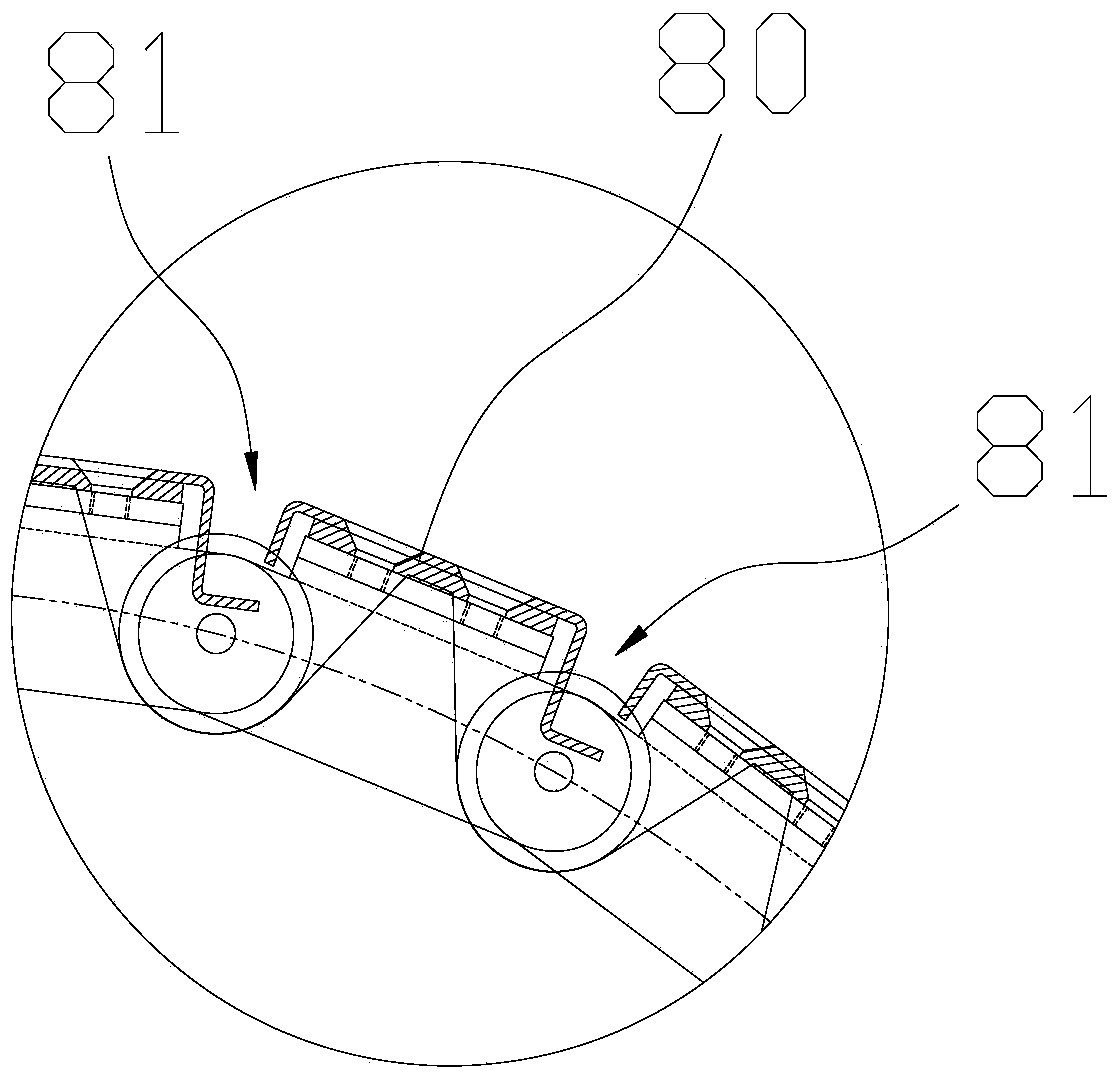

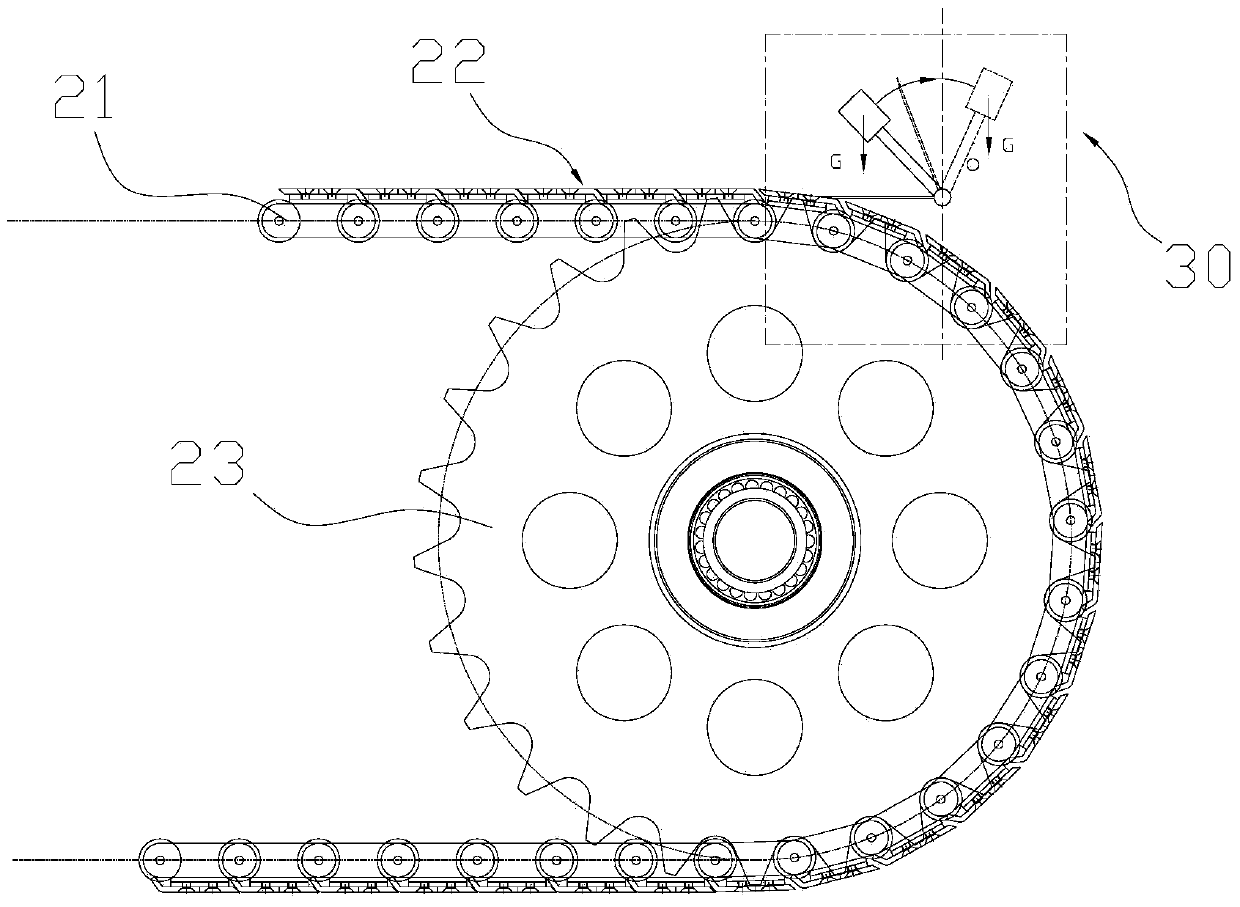

[0024] see Figure 3 to Figure 6 , which is a chain-plate type baking tunnel furnace of the present invention, comprising a cabinet (not shown) with a baking channel, a conveying device and a heating device (not shown) arranged in the cabinet, the cabinet is designed to There is a box body with an input end and an output end, and the space in the box forms the baking channel; the heating device is used to heat the air in the cabinet; the transmission device includes a transmission chain 21, which is fixed outside the transmission chain 21 The chain plate belt 22 on the surface and the drive sprocket 23 that is connected with the transmission chain 21 and is used to provide traction. The chain plate belt 22 is made up of a plurality of chain plates 221 arranged side by side along the length direction of the transmission chain 21. The chain plate 221 inc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com