Method for reducing levels of crude protein and phosphorus in fattening pig compound feed

A compound feed and crude protein technology, applied in animal feed, animal feed, application, etc., can solve the problems of affecting the absorption of mineral elements, not digesting phytate phosphorus, and low digestion and absorption rate, and achieve the level of reducing nitrogen and phosphorus Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

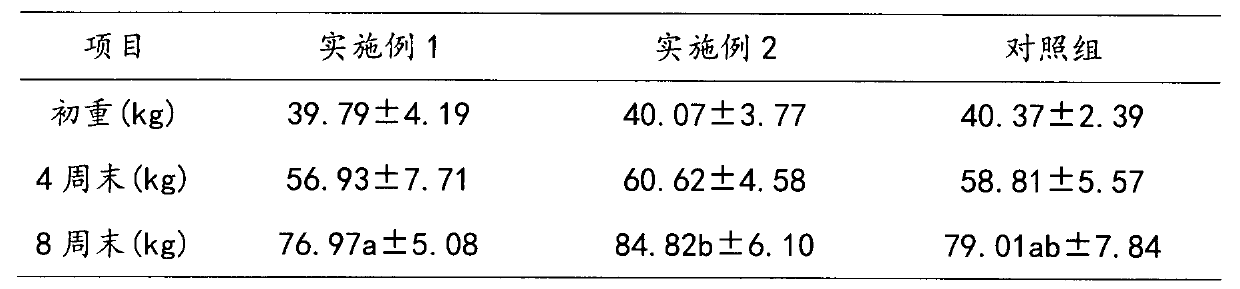

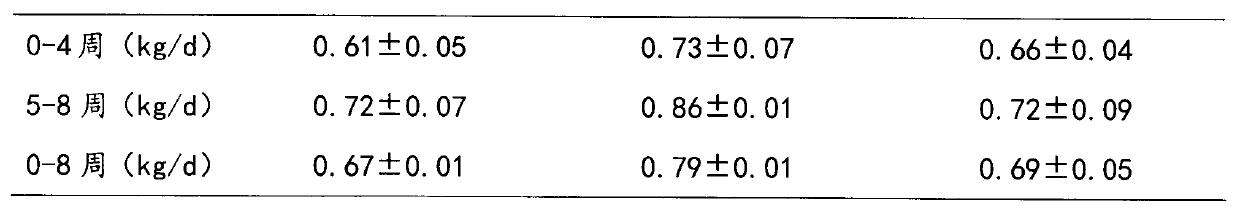

Examples

Embodiment 1

[0014] The compound feed for reducing crude protein and phosphorus levels in the fattening pig compound feed provided by this example is prepared by mixing the following components in mass percentage: 66.89% of corn, 11.0% of soybean meal, 19.00% of bran, 1.00% of stone powder, Calcium hydrogen phosphate 0.61%, salt 0.5%, premix 1%. Among them, every kilogram of premix contains 140g of lysine, 85g of methionine, 2.50g of copper, 8.00g of zinc, 8.00g of iron, 4.00g of manganese, 15mg of iodine, 20mg of selenium, and 50g of compound multidimensional for pigs (purchased from Nanjing Purina Feed company), 15 grams of phytase (1 gram=5000 units, purchased from Guangdong VTR Biotechnology Co., Ltd.), and bran to make up the balance.

Embodiment 2

[0016] The compound feed for reducing crude protein and phosphorus levels in the fattening pig compound feed provided by this example is prepared by mixing the following components in mass percentage: 63.97% of corn, 14.00% of soybean meal, 19.00% of bran, 1.05% of stone powder, Calcium hydrogen phosphate 0.48%, salt 0.5%, premix 1%. Among them, every kilogram of premix contains 100g of lysine, 75g of methionine, 2.50g of copper, 8.00g of zinc, 8.00g of iron, 4.00g of manganese, 15mg of iodine, 20mg of selenium, and 50g of compound multidimensional for pigs (purchased from Nanjing Purina Feed company), 20 grams of phytase (1 gram=5000 units), and the bran makes up the balance.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap