An emulsifying and stirring equipment with the functions of grinding, rubbing and grinding

A technology of mixing equipment and functions, applied in the field of emulsification mixing equipment, to achieve the effect of improving mixing efficiency and reliable placement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

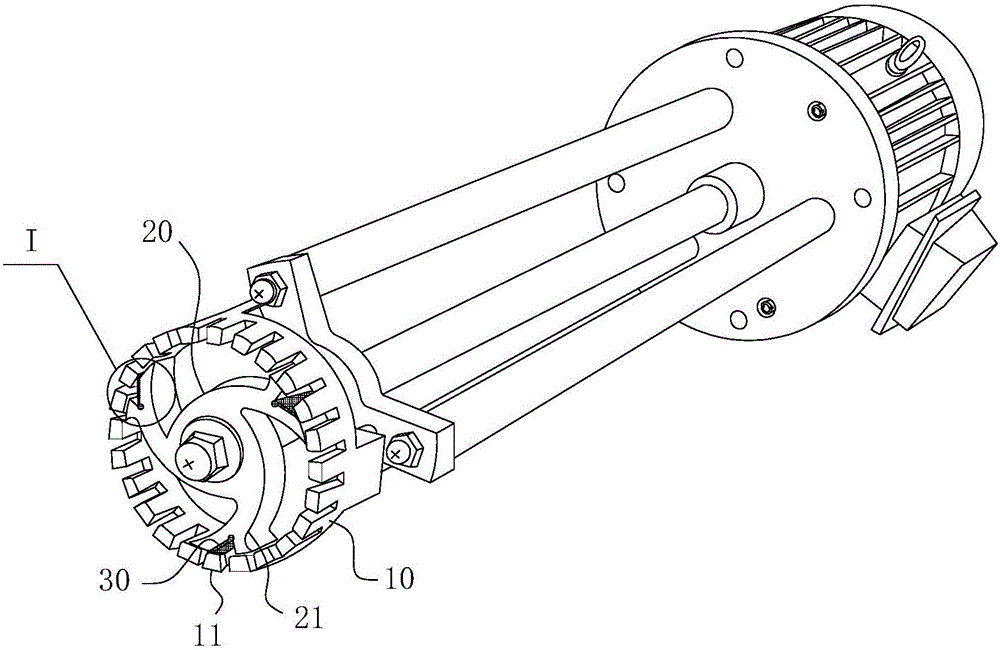

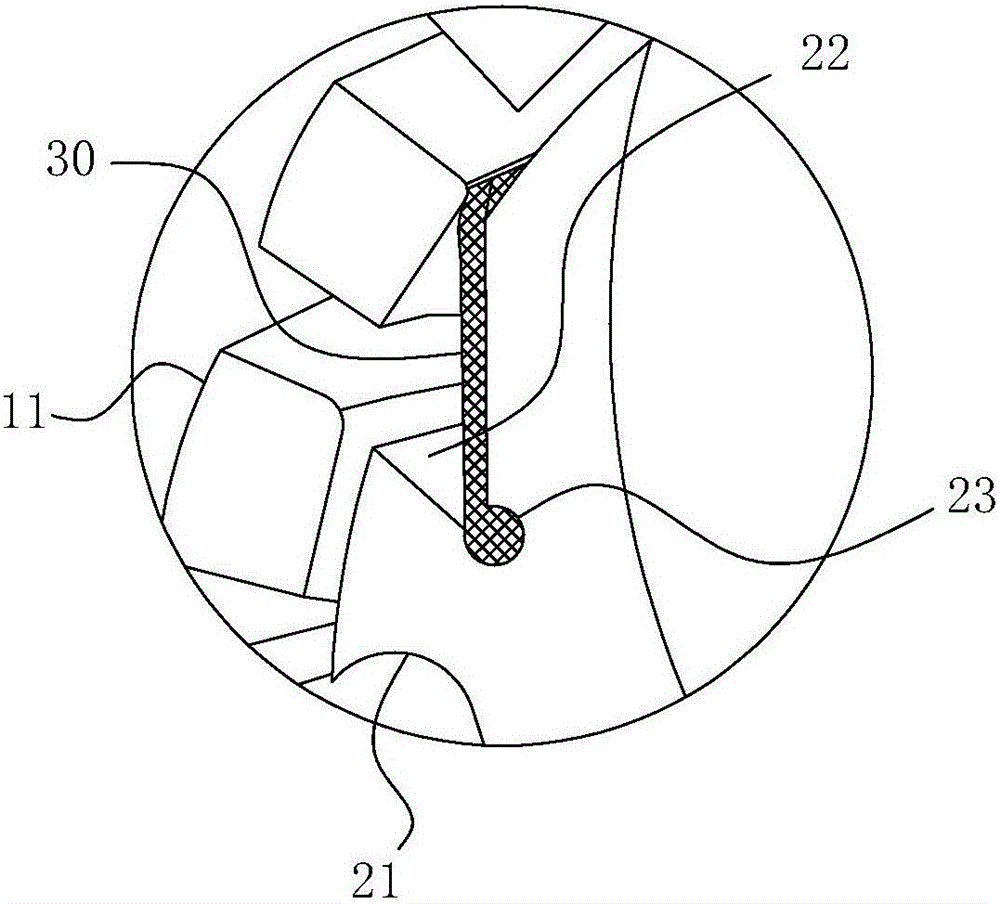

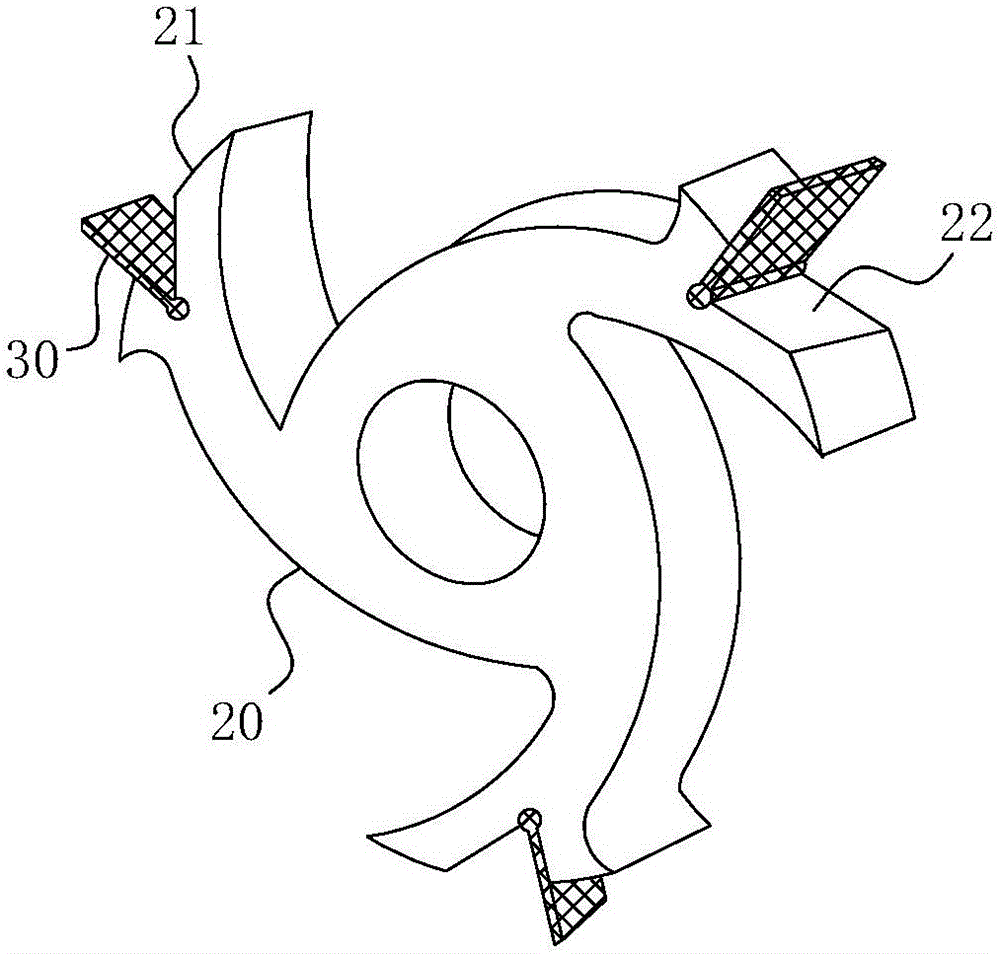

[0037] For ease of understanding, combine here Figure 1-12 The structure and specific work flow of the present invention are further elaborated as follows:

[0038] The structure of the present invention is as Figure 1-12 As shown, it specifically includes a stator 10 and a rotor 20 that form a coaxial rotation fit with each other. The stator 10 is provided with a plurality of protruding teeth 11 along its axial direction, and each protruding tooth 11 surrounds the axis of the stator 10 to form a complete circle. Ring; and the rotor 20 or directly contained in the annular convex teeth 11 of the stator. When the rotor 20 rotates, the outer edge surface of the rotor 20 and the inner edge surface of each convex tooth 11 move relative to each other.

[0039] The key point of the design of the present invention is that between the rotating mating surface of the stator 10 and the rotor 20, that is, the outer edge surface of the rotor 20 and the inner edge surface of the convex teeth 11...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com