Cymbal maker

A rack and drive wheel technology, applied in the field of cymbal manufacturing equipment, cymbal making equipment, and musical instrument manufacturing equipment, can solve the problems of inconvenience, time-consuming and laborious, repeated processing, etc., to achieve stable transmission and good craftsmanship Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

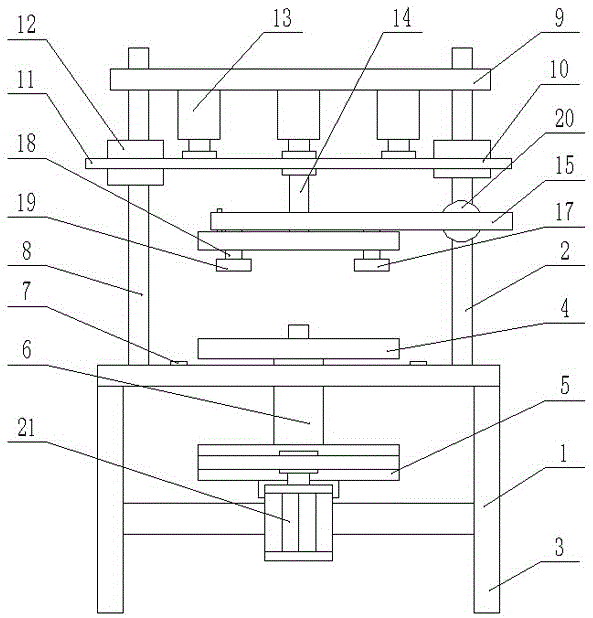

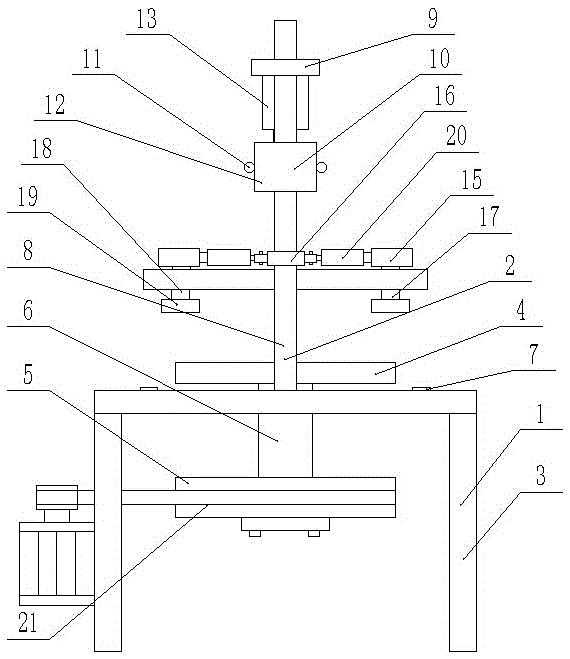

[0024] Such as Figure 1-2 As shown, the cymbal maker includes a frame 1 and a bracket 2 fixedly arranged on the upper part of the frame 1. The frame 1 is supported by four legs 3, a positioning plate 4 is arranged above the frame 1, and the frame 1 A drive wheel 5 is provided below the locating disk 4 and the drive wheel 5 is connected by a shaft 6 provided on the frame 1, and the shaft 6 is connected with the frame 1 by a bearing, and the drive wheel 5 can drive The positioning disk 4 rotates, and the upper part of the frame 1 is also provided with a plurality of protrusions 7 which are uniformly distributed around the center of the positioning disk 4, and the plurality of protrusions 7 are all arranged on the center of the positioning disk 4. external.

[0025] Wherein, the bracket 2 includes two support rods 8 arranged vertically. The upper ends of the two support rods 8 are fixedly provided with a top frame 9, and a movable horizontal frame 10 is provided between the top fra...

Embodiment 2

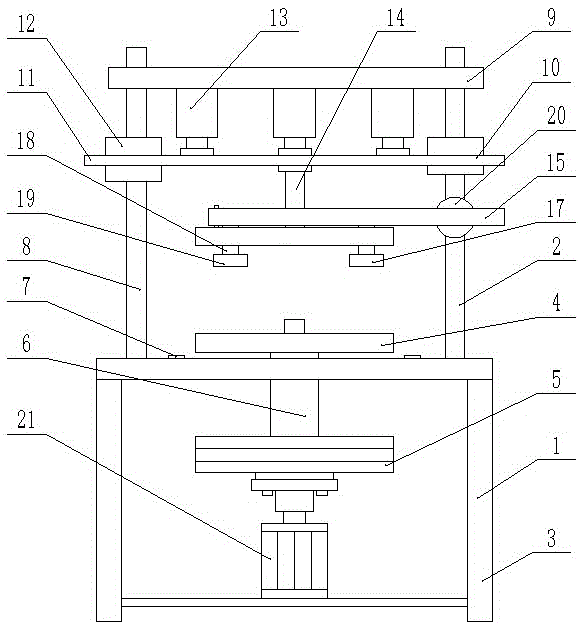

[0034] Such as Figure 3-4 As shown, the difference between this embodiment and the first embodiment is: the power unit 21 of the present invention is a hydraulic motor, the transmission of the hydraulic system is stable, and the produced cymbals have good manufacturability.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com