Gear-rack log splitter with clutch

A rack and pinion technology with a clutch, which is applied in the direction of splitting devices, wood processing equipment, manufacturing tools, etc., can solve the problems that the knives cannot be retracted quickly, affect the work efficiency, and the transmission rate is low, so as to avoid the service life of the knives The effect of reducing, improving production efficiency, and controlling high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

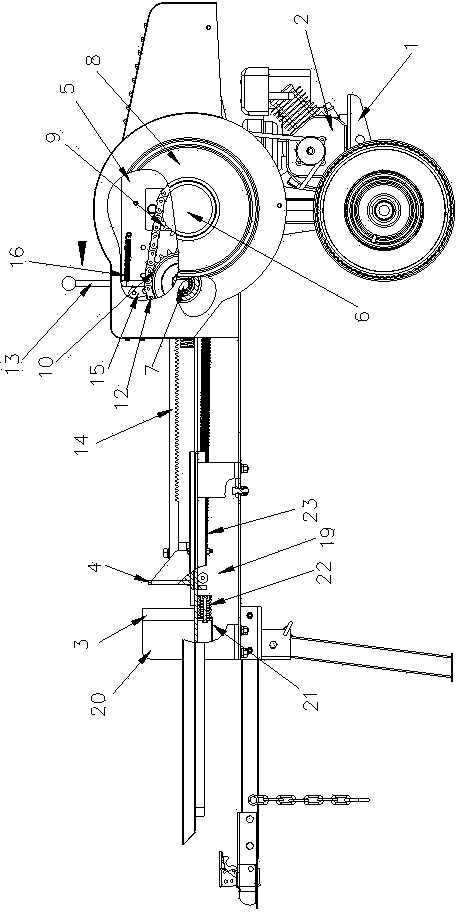

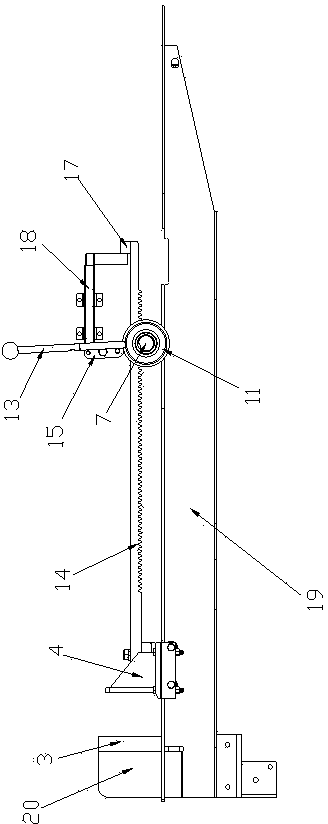

[0012] like figure 1 and figure 2 As shown, a rack and pinion wood splitter with clutch described in this embodiment includes an engine mount 1, an engine 2, a cutter 3 and a push plate 4, the engine 2 is arranged on the engine mount 1, and the engine mount 1 The front end is provided with a frame 5, which is characterized in that the frame 5 is provided with a power input shaft 6, a gear shaft 7 and an operating handle 13, and the power input shaft 6 is provided with a flywheel 8 and a first sprocket 9, and the engine 2 passes through The belt is connected with the flywheel 6, the gear shaft 7 is provided with a second sprocket 10 and a clutch 11, the input part of the clutch 11 is connected with the flywheel 6, the operating handle 13 is connected with the output part of the clutch 11, the first sprocket 9 and the second The sprocket 10 is connected by a chain 12, the frame 5 is provided with a rack 14, the push plate is located on the rack 14, the bottom of the rack 14 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com