Injection mould of plastic globe

A globe and plastic technology, applied in the direction of coating, etc., can solve the problems of distortion, shrinkage and wrinkling of PVC hemispherical map film, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

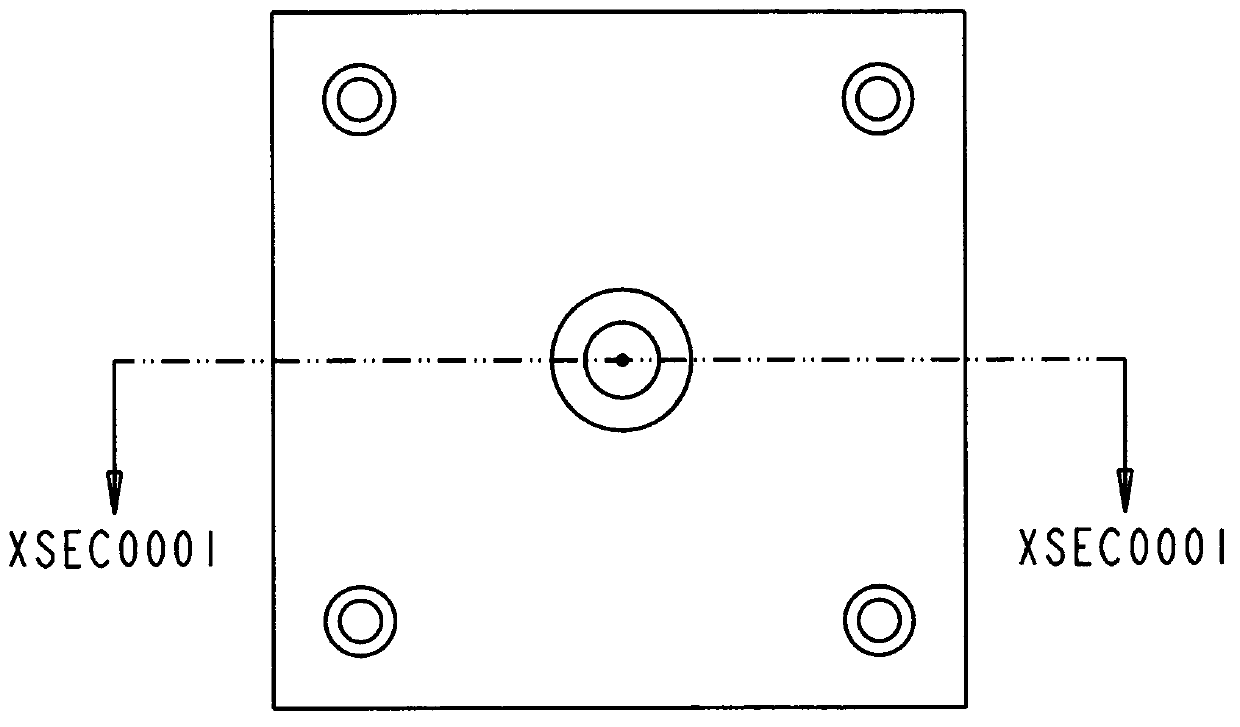

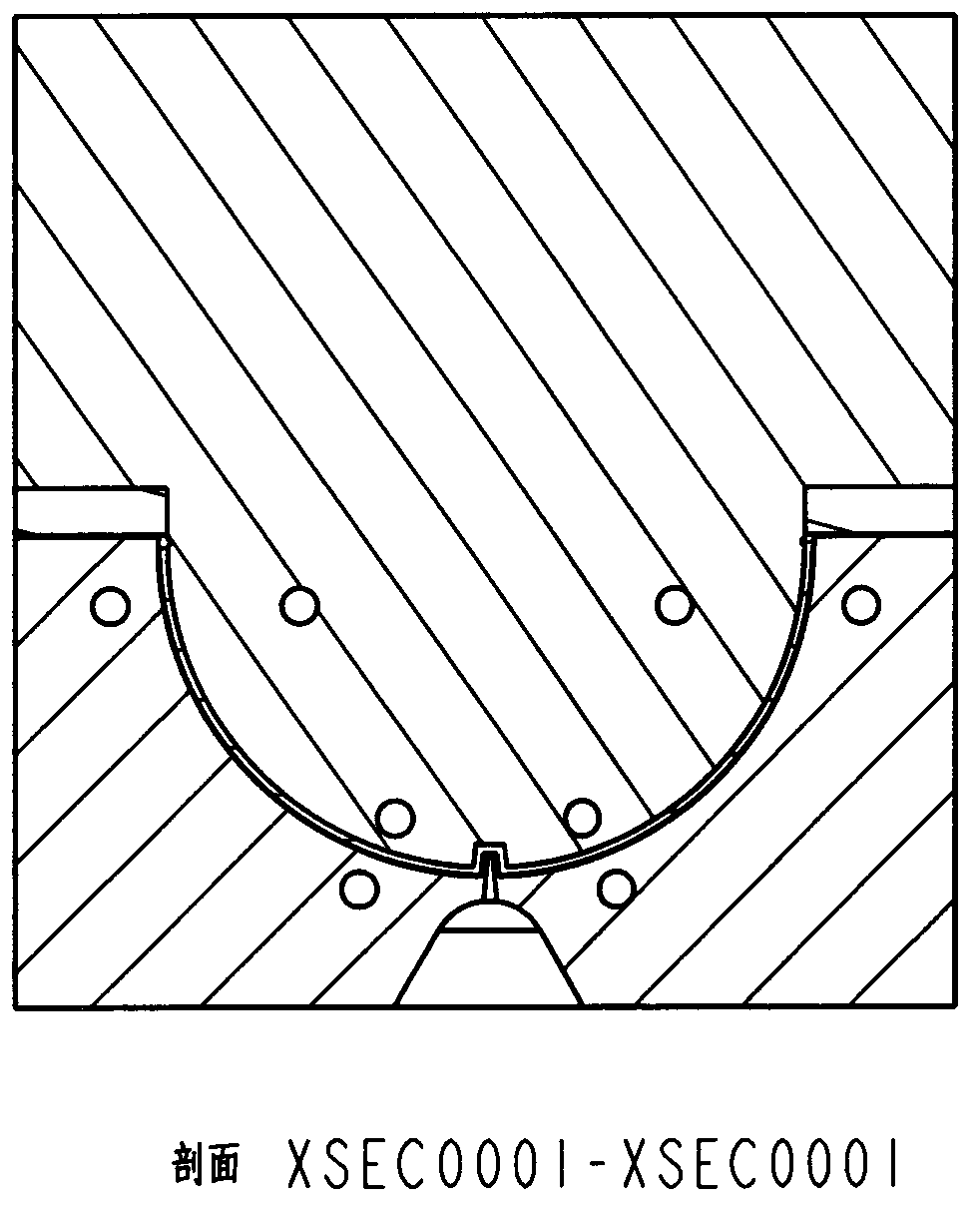

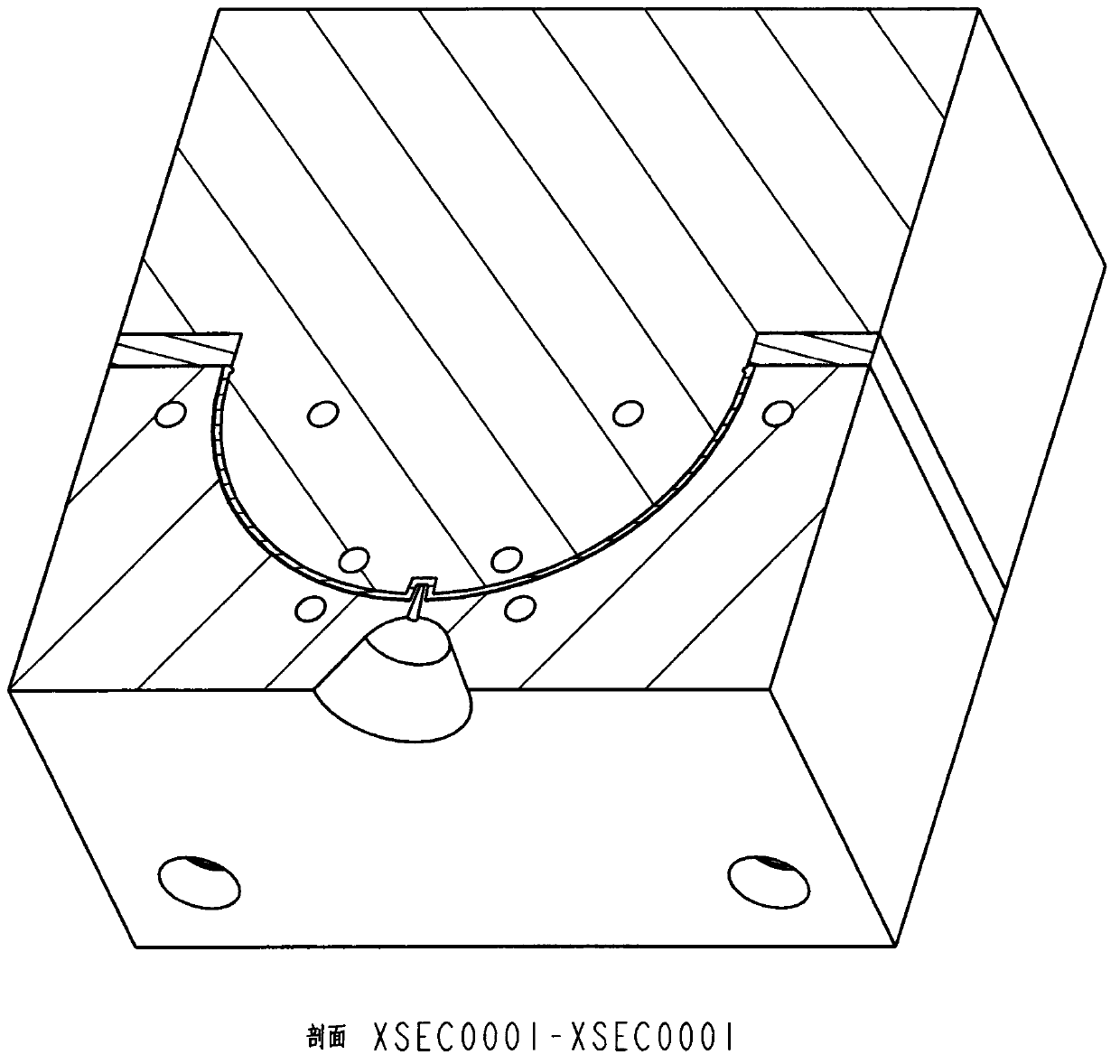

[0011] An injection molding mold for a plastic globe with a plastic sphere and a PVC film map bonded firmly. The technical solution for achieving the above purpose: an injection mold, including a fixed mold 9 , a movable mold 1 , and a top plate 6 . The fixed mold 9 is a concave hemispherical shape, and the fixed mold is provided with positioning nails 11. The effect of the positioning nails 11 is to position the PVC map hemispherical membrane 8. The winding 10 is in the middle of the positioning nails 11, and the parting surface of the fixed mold 9 is opened Exhaust groove 12 is arranged, and two groups of cooling waters are arranged on fixed mold 9, and one group of ice water 4 less than 4 ℃ is on the concave hemispherical top, and another group of normal temperature cooling water 3 is on the concave hemispherical top. The movable mold 1 is a raised hemispherical shape, and the movable mold 1 is provided with a runner 5 at the top of the raised hemispherical shape, so that t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com