A car tie rod assembly

An automobile tie rod and assembly technology, which is applied to steering tie rods, vehicle parts, steering mechanisms, etc., can solve the problems of complex process and structure, high production cost, low bearing strength, etc., and achieves simple structure, simplified production process, and improved bearing capacity. the effect of strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The specific embodiment of the present invention will be described in further detail by describing the embodiments below with reference to the accompanying drawings, the purpose is to help those skilled in the art to have a more complete, accurate and in-depth understanding of the concept and technical solutions of the present invention, and contribute to its implementation.

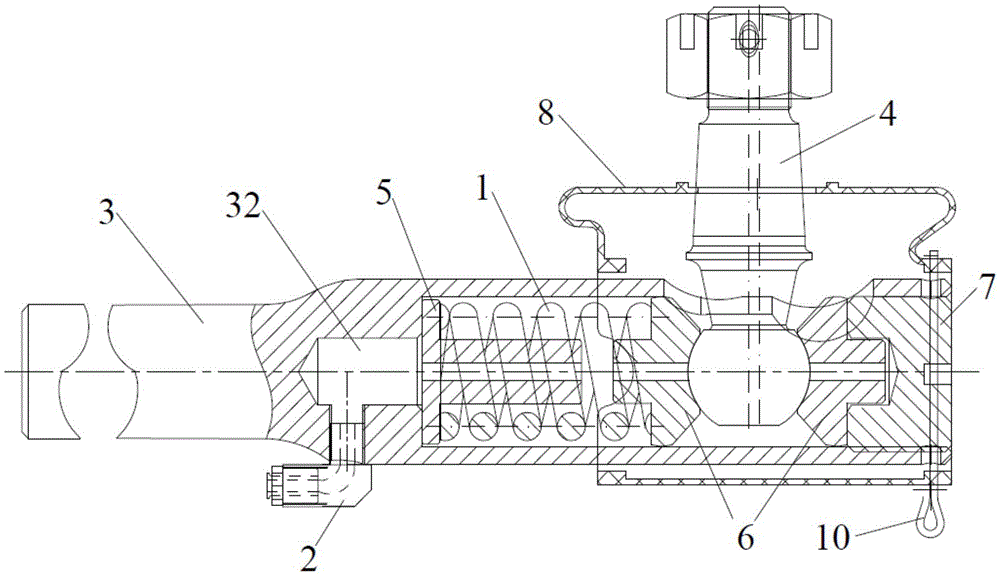

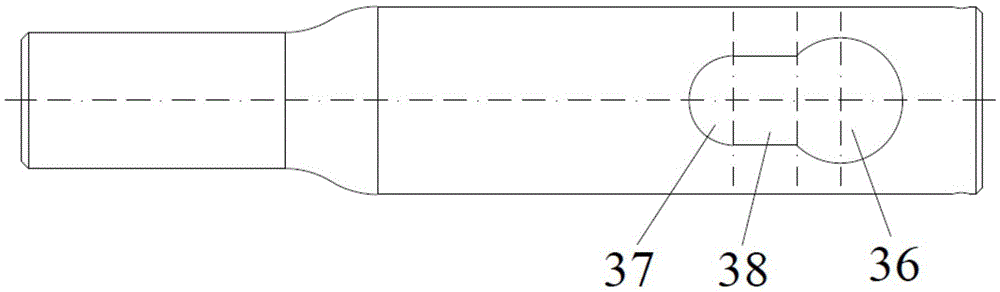

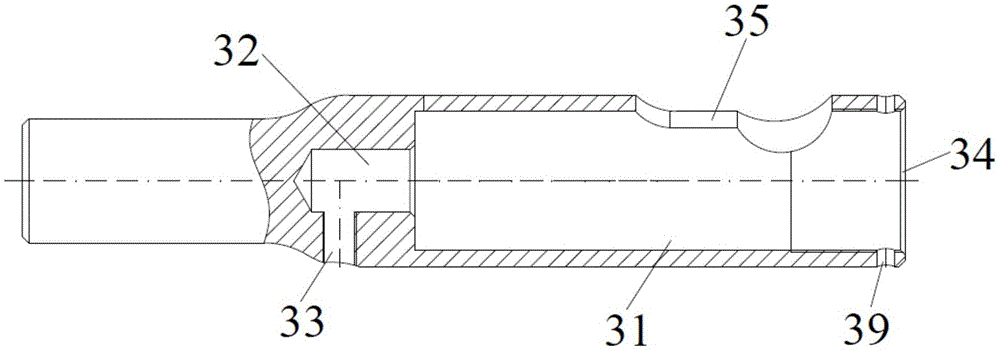

[0038] Such as Figure 1 to Figure 12 As shown, an automobile tie rod assembly of the present invention includes a tie rod 3, a ball pin 4 and a ball seat structure for supporting the ball pin 4, the ball pin 4 includes a ball head 41 and a ball pin rod 42, and the ball head 41 is installed on the ball The end portion of pin rod 42, and both are coaxial. The tie rod 3 of the automobile tie rod assembly is provided with an accommodating chamber 31 for accommodating the ball seat structure and the ball head 41, that is, the ball head 41 of the ball pin 4 is inserted into the accommodating chamber 3...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap