Mounting structure for automobile auxiliary frame at front section of engine cabin boundary beam

A technology for the engine compartment and sub-frame, applied in the substructure, vehicle parts, transportation and packaging, etc., can solve problems such as attitude changes, bolt torsion attenuation, and impact on chassis performance, and achieve high performance levels and ensure strength and rigidity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings.

[0019] As an important component of the chassis system, the sub-frame of the front rear drive vehicle is installed on the lower surface of the front section of the side beam of the engine compartment, and the matching parts are the front section of the side beam of the engine compartment (left and right).

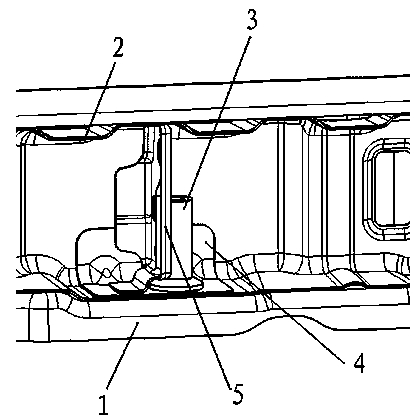

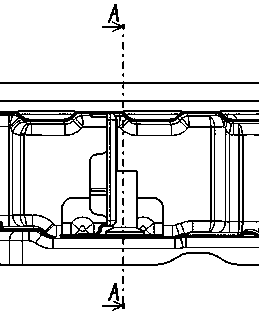

[0020] Such as figure 1 As shown, the present invention is made up of following several parts: engine compartment side beam front section 1, engine compartment side beam front section reinforcement 2, subframe installation threaded pipe 3, subframe installation nut plate 4 and thread pipe reinforcement plate 5.

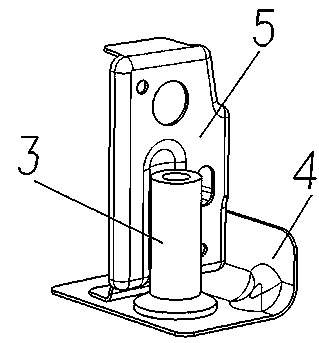

[0021] see figure 2 , The sub-frame installation threaded pipe 3 and the L-shaped sub-frame installation nut plate 4 are connected together by CO2 welding. The threaded pipe reinforcing plate 5 is a vertical plate, which is vertically attached t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com