A method for detecting the tension of a circular link chain on a scraper conveyor

A scraper conveyor and circular chain technology, which is applied to conveyor objects, conveyor control devices, transportation and packaging, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

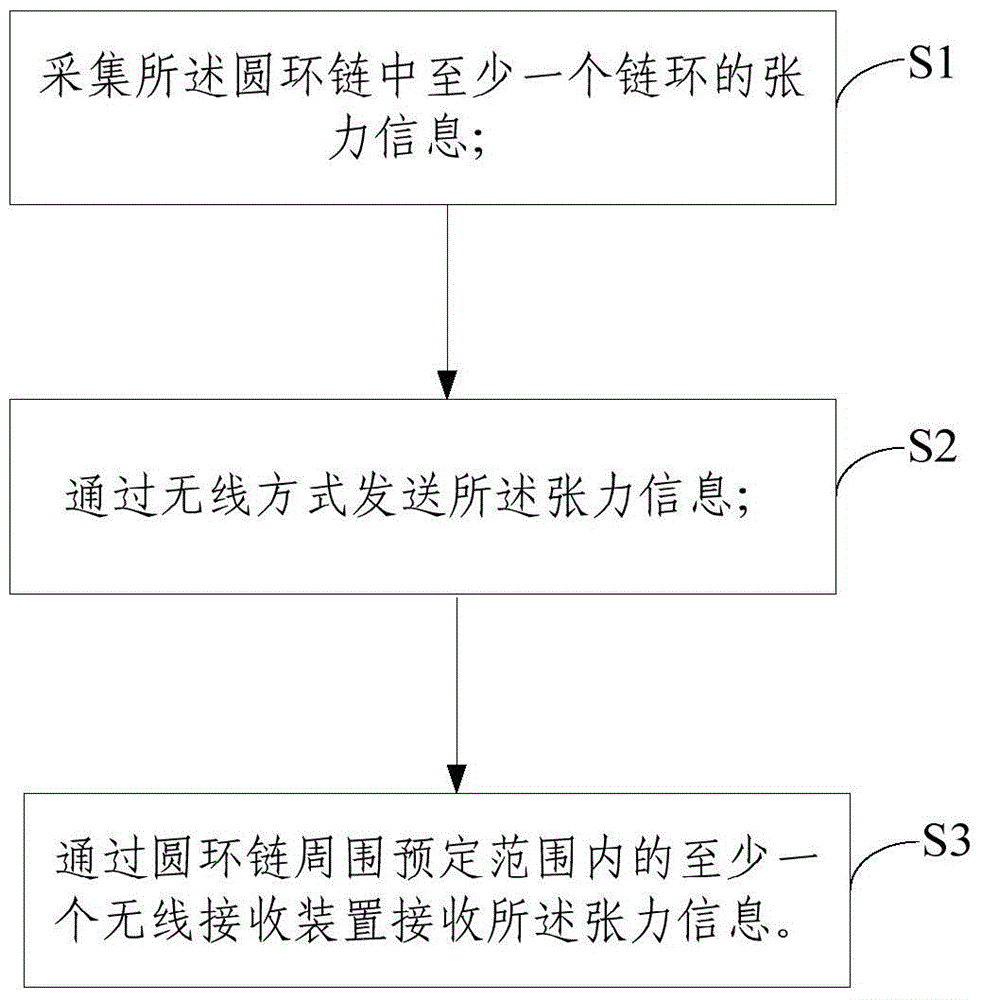

[0021] figure 1 A flow chart showing the method of the present invention for detecting the tension of a circular link chain on a scraper conveyor;

[0022] refer to figure 1 , a method for detecting the tension of a circular link chain on a scraper conveyor according to an embodiment of the present invention includes:

[0023] S1, collecting tension information of at least one link in the circular link chain;

[0024] S2. Send the tension information wirelessly;

[0025] S3. Receive the tension information through at least one wireless receiving device within a predetermined range around the circular link chain.

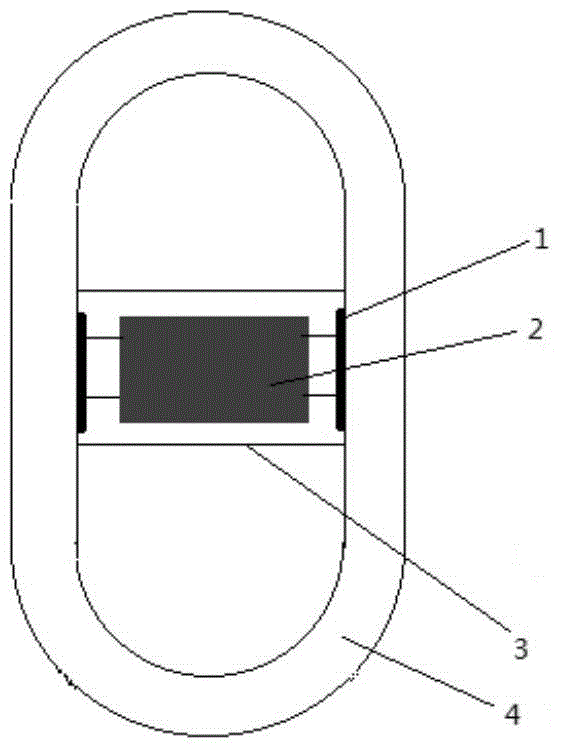

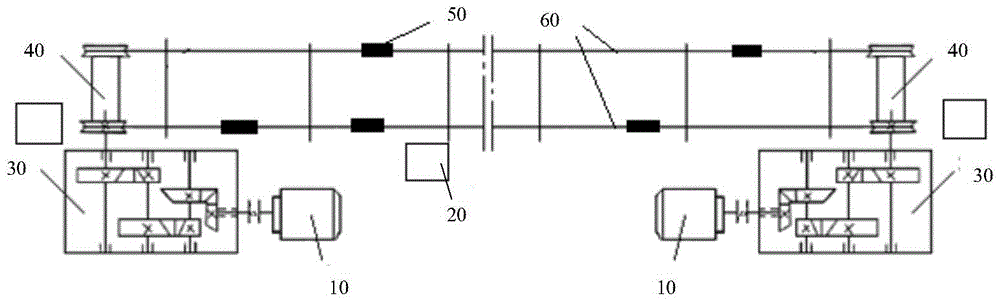

[0026] In one embodiment, the tension information is collected by a tension sensor arranged on a link at intervals of a preset number of links on the circular link chain.

[0027] Specifically, the circular link chain of the scraper convey...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com