Sealing detection device and method for electric rotating connector

A rotary connector and seal detection technology, which is applied in the direction of liquid tightness measurement using liquid/vacuum degree, can solve the problems of potential safety hazards, the inability to accurately determine the dynamic sealing performance, and the inability to detect the dynamic sealing performance of electric rotary connectors. To achieve the effect of ensuring reliability and good sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

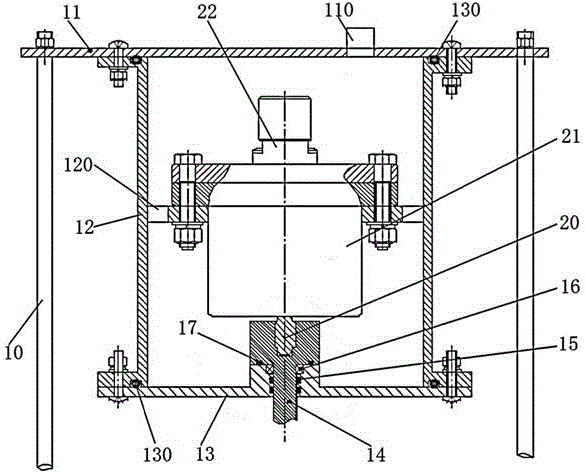

[0017] The electrical rotary connector seal detection device of the present invention will be described in detail below in conjunction with the accompanying drawings:

[0018] Embodiment 1 of the electrical rotary connector seal detection device of the present invention: as figure 1 As shown, it includes a sealed box. In this embodiment, the sealed box includes a cylinder 12. The cylinder 12 extends in the up and down direction and has openings at the upper and lower ends. The upper and lower ends of the cylinder 12 are respectively provided with connecting flanges, and through The connecting flange is respectively connected with an upper end cover 11 and a lower end cover 13, and the connecting flange is provided with a sealing groove 130, and a sealing ring is installed in the sealing groove, and the upper end cover 11 is provided with a water inlet 110 for injecting water into the sealed box. The body 12 is provided with a fixing structure for fixing the shell of the electr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com