Positive pressure sealing performance test device and method for syringe

A technology of test device and test method, applied in liquid/vacuum measurement for liquid tightness, by detecting the appearance of fluid at the leak point, etc., which can solve the problem of liquid leakage, cannot provide continuous and stable lateral force, and cannot test syringes Sealing performance and other issues, to achieve the effect of fewer operation steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 2

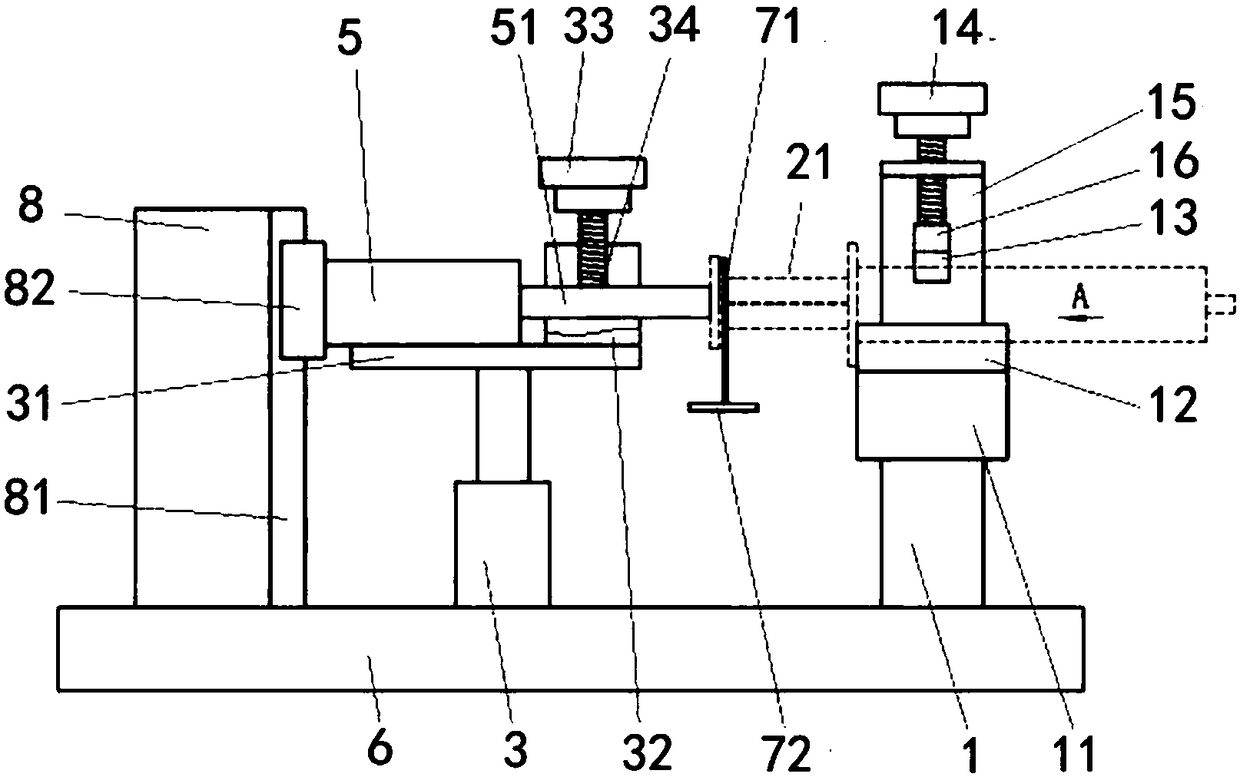

[0054] This specific embodiment discloses a positive pressure tightness test method for a syringe, the method adopts the positive pressure tightness test device for a syringe disclosed in the first embodiment, including the steps:

[0055] S10: Inject water larger than the nominal volume into the syringe;

[0056] S20: Press the plunger of the syringe to discharge the air in the syringe, adjust the water volume in the syringe to its nominal capacity or to a position less than or equal to its nominal capacity, and seal the cone of the syringe;

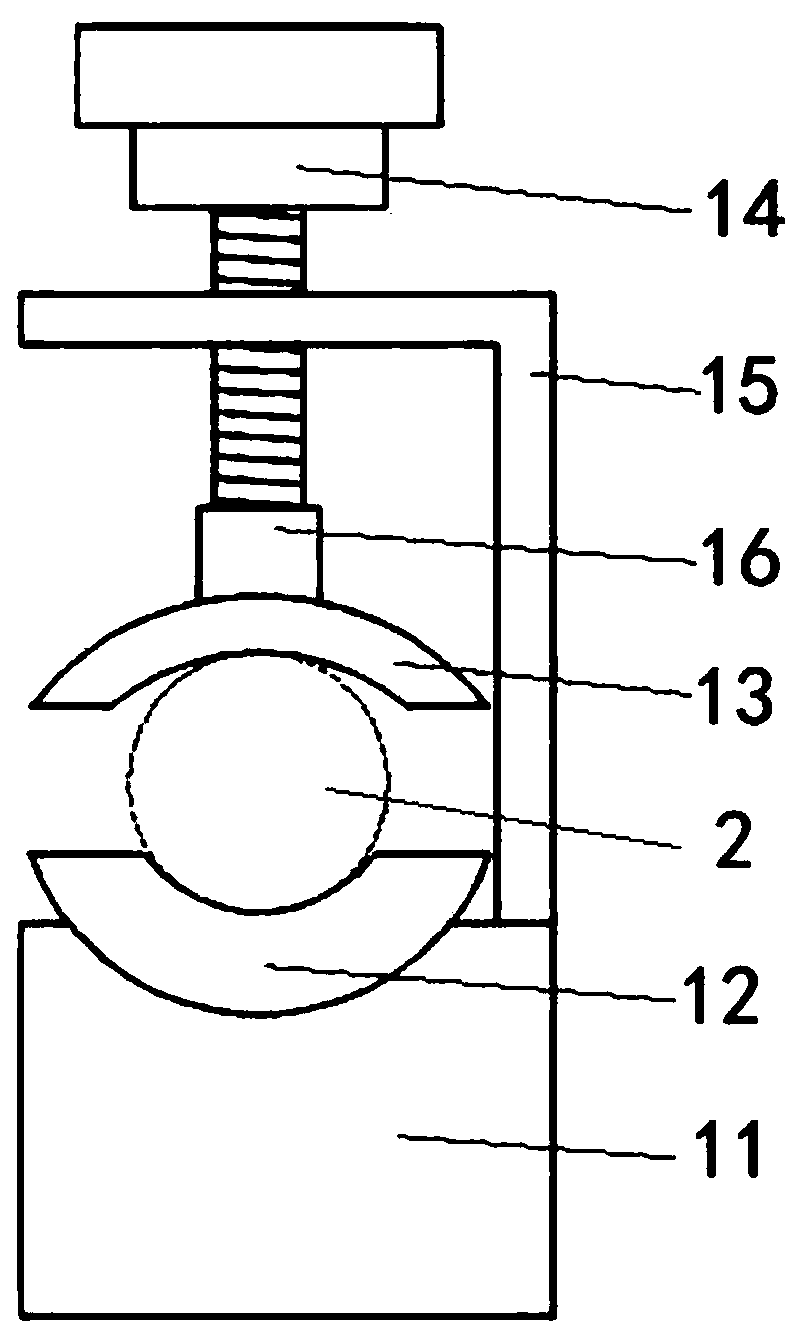

[0057] S30: placing the syringe flat on the first installation part on the first support frame;

[0058] S40: hang a weight frame on the end of the core rod of the syringe, gradually add weights on the weight frame according to preset standards, and the weight exerts a lateral force on the core rod of the syringe through its own gravity;

[0059] S50: When the core rod is subjected to the lateral force exerted by the weight, check whet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com