Locking device for operating handle of hydraulic bracket of fully mechanized mining machine

A technology of operating handles and hydraulic supports, which is applied in the direction of mine roof supports, pillars/supports, mining equipment, etc., can solve problems such as safety hazards, poor sightlines, and poor environments, and achieve easy installation and management, avoid safety hazards, and use convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention is further described below in conjunction with embodiment; The following embodiment is not for the limitation of the present invention, only as the mode of supporting the realization of the present invention, any equivalent structural replacement within the technical framework disclosed in the present invention, all is the present invention. the scope of protection of the invention;

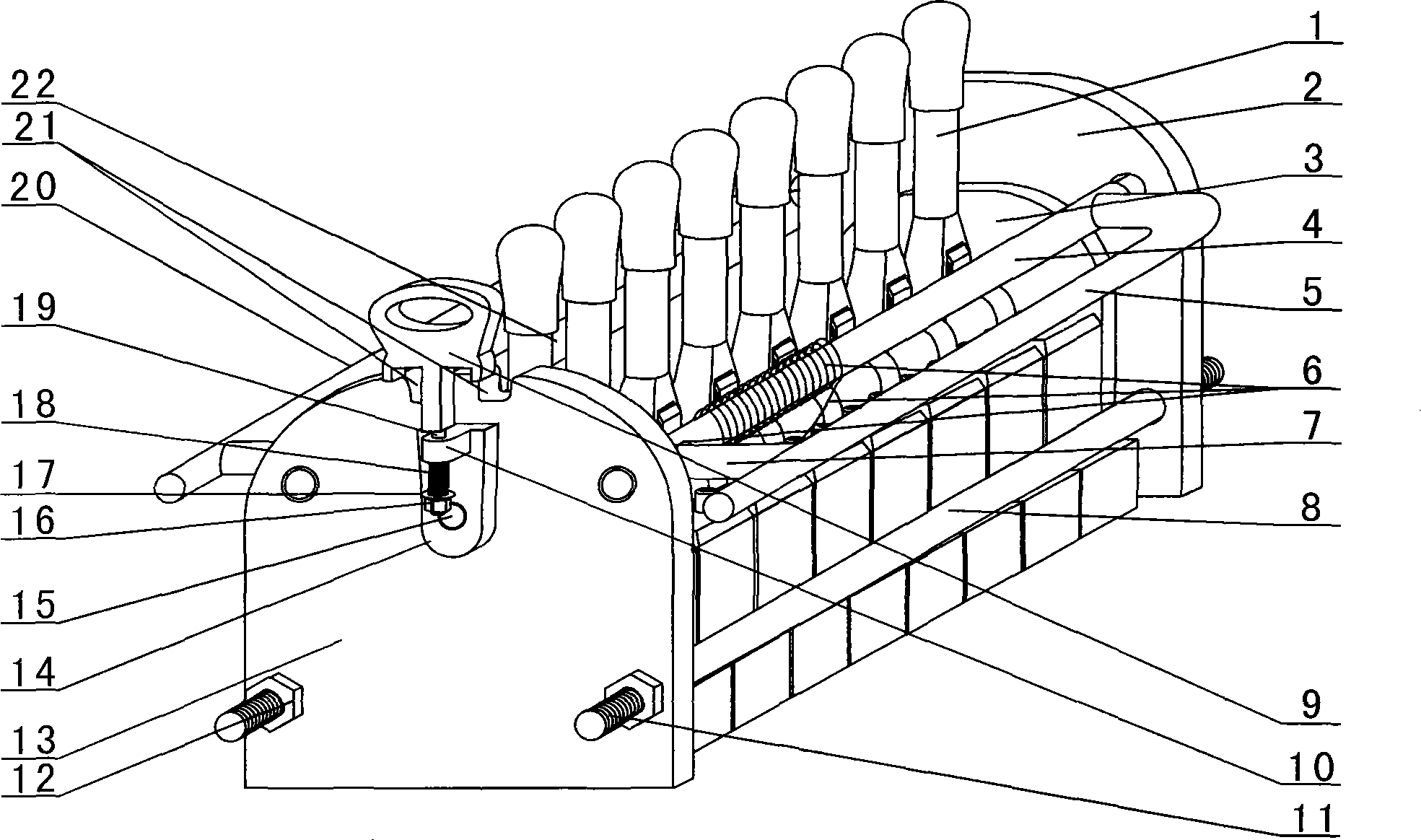

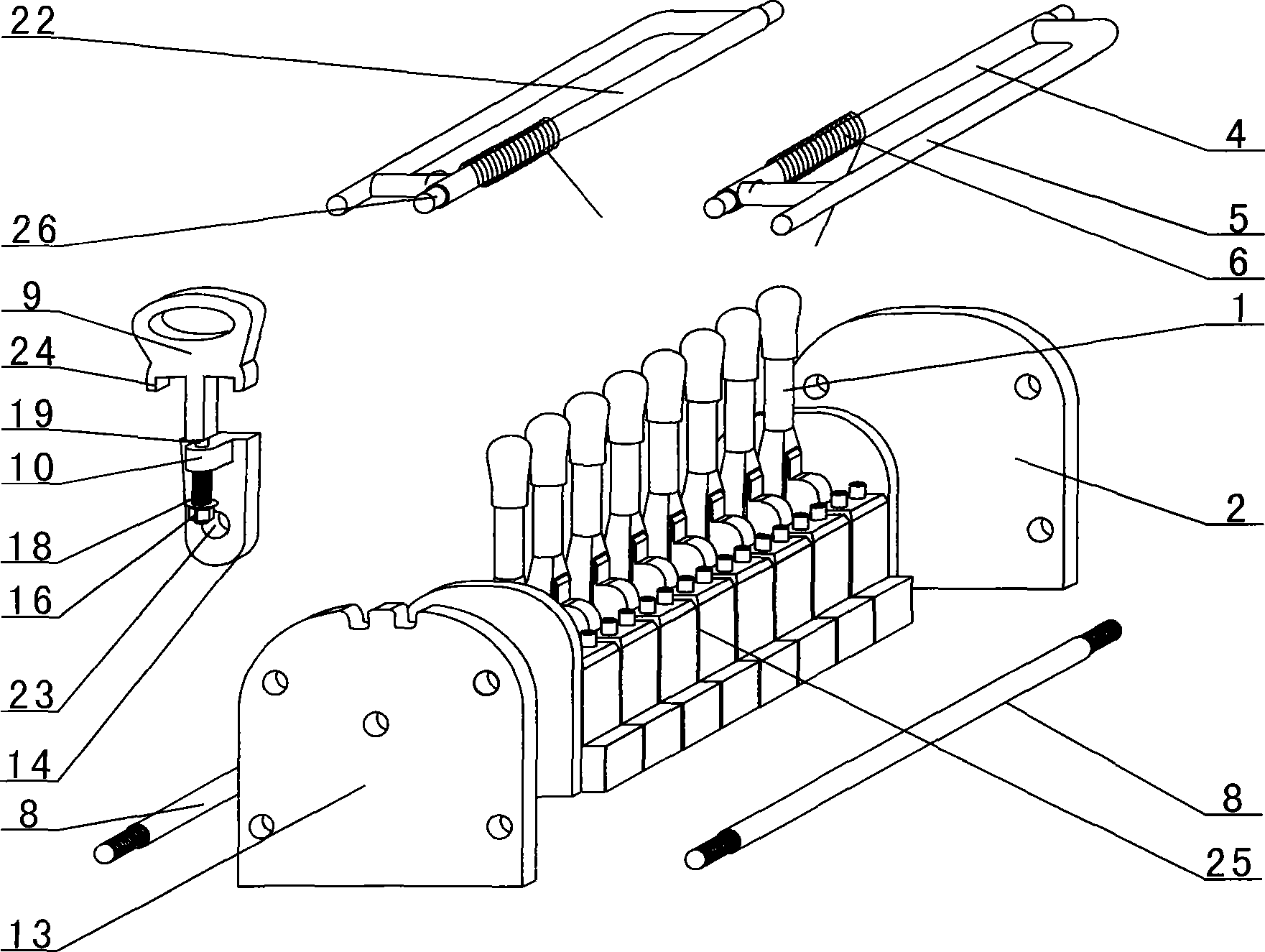

[0015] combined with figure 1 Or the fully-mechanized mining machine hydraulic support operating handle locking device described in 2 includes a fully-mechanized mining machine operating handle, and the fully-mechanized mining machine operating handle is composed of a plurality of parallel control valves 25, operating handles 1 and guard plates 3; The two ends of a parallel control valve are respectively provided with protective plates 3, and the upper part of each control valve is respectively provided with an operating handle 1; one end steel plate 2 and the other e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com