9-shaped pipe for supporting

A font-shaped and special-shaped technology, applied in the field of special-shaped square and rectangular pipes, can solve problems such as limited cross-sectional performance, many processing and welding links, and complicated installation processes, and achieve the effect of broadening the scope of use and increasing product varieties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

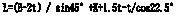

[0009] 9-shaped tube for special-shaped support, including a whole piece of cold-formed 9-shaped steel plate, there is a welding seam (6) at the butt joint of the steel plate, and the welding form can be selected according to the wall thickness (7) and material of the steel plate. High-frequency continuous welding , submerged arc continuous welding, laser continuous welding or gas shielded continuous welding, characterized in that: the section is 9-shaped, the four corners of the outer contour of the pipe wall are all outer arcs (1), and the radius of the outer arc is the thickness of the steel plate ( 7) 2~4 times; the four corners of the inner contour are all inner arcs (2), and the inner arc radius is 1~2.5 times the steel plate wall thickness (7); the width of the 9-shaped steel plate (9) The range is 40mm~200mm, the range of height (4) is 80mm~400mm, the ratio of width (9) to height (4) is 1:2~1:3.5; the height value of the short side of the closed part (3) is 20mm~200mm; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wall thickness | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com