Testing method for wheel loader energy efficiency

A technology of wheel loader and testing method, which is applied in the testing of machine/structural components, measuring devices, instruments, etc., can solve the problems of low accuracy, lack of weighing of shovel-loaded materials, and lack of evaluation of energy efficiency indicators.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

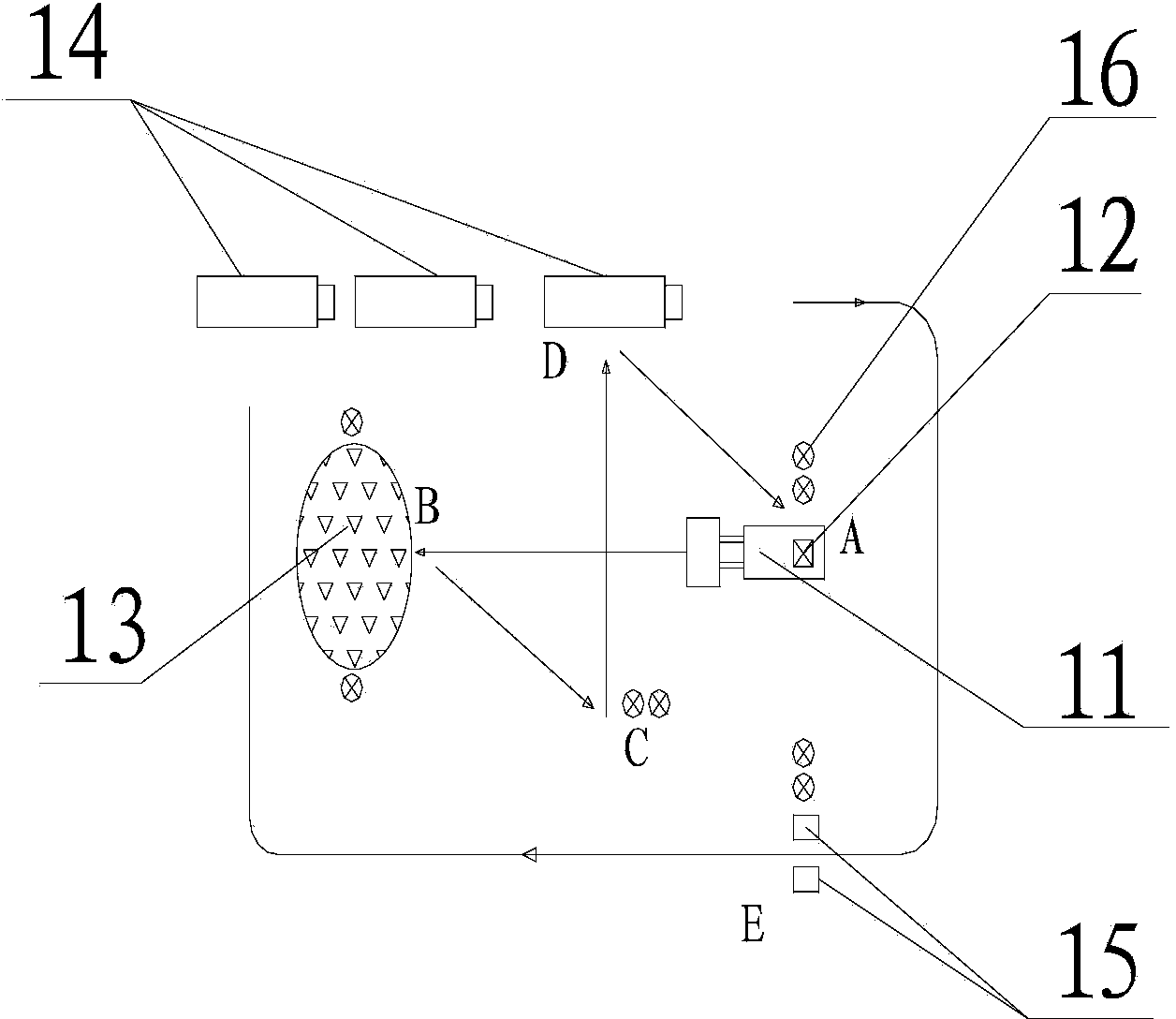

[0037] The present invention will be described in further detail below through specific implementation examples and in conjunction with the accompanying drawings.

[0038] An embodiment of the present invention provides a method for testing the energy efficiency of a wheel loader 11, including:

[0039] 1) Place the wheel loader 11 at a position facing the test material 13 with a first preset distance from the test material 13 .

[0040] Specifically, in the test method for the energy efficiency of the loader provided in this embodiment, it is first necessary to prepare the equipment for the test, namely: the wheel loader 11 to be tested, the test material 13, the auxiliary fuel tank 12, the first weighing device and the second loader. 2. Weighing device.

[0041] Specifically, the first preset distance is preferably 15 meters to 25 meters, and more specifically, is preferably 20 meters. Among them, 15 meters, 16 meters, 17 meters, 18 meters, 19 meters, 20 meters, 21 meters,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com