Optical fiber connector and optical fiber connector assembly using optical fiber connector

A technology for optical fiber connectors and components, which is applied in the coupling of optical waveguides, etc., can solve the problems of poor tensile strength of optical fiber connectors, detachment of pins, affecting the connection effect of optical fiber connectors, etc., so as to ensure the quality of signal transmission, The effect of reducing radial size and improving tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

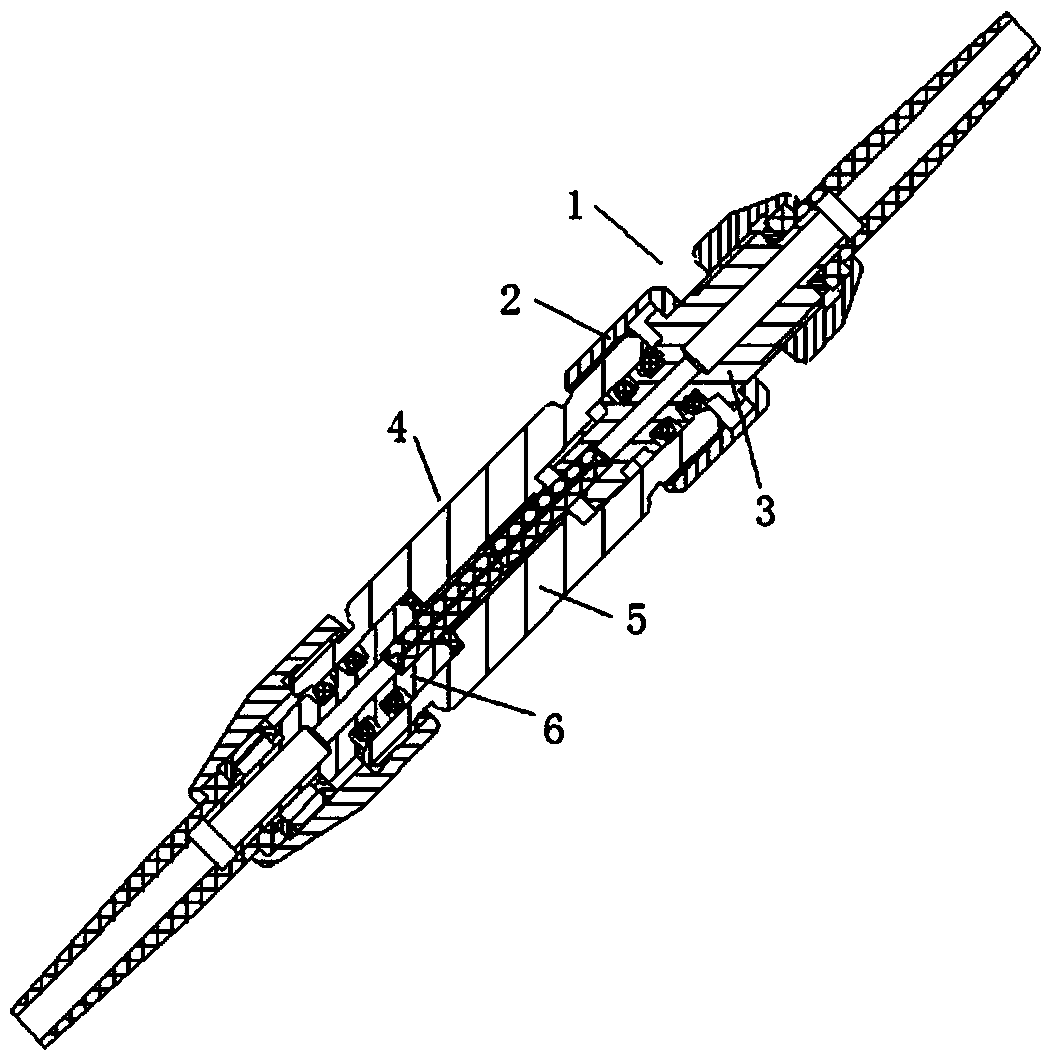

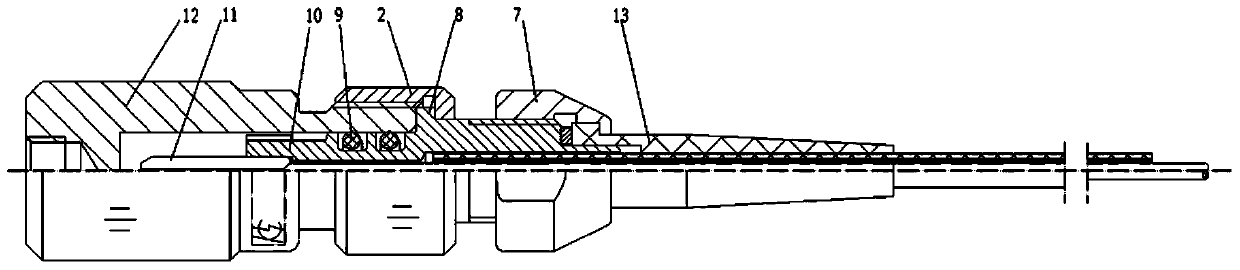

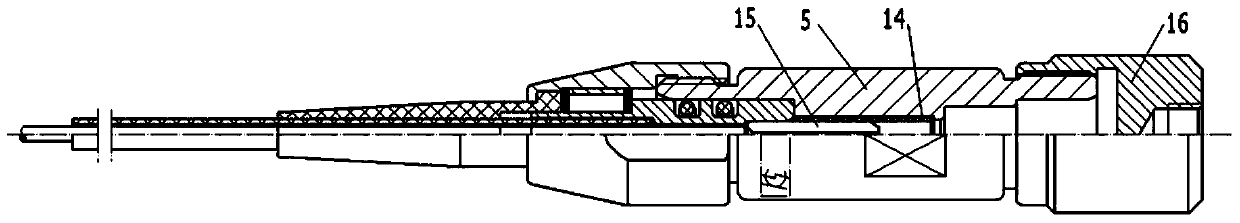

[0016] Examples of fiber optic connector assemblies are Figure 1~3 Shown: includes a plug 1 and a socket 4, the socket includes a socket housing 5 and a socket pin part 6 fixedly installed in the socket housing, and the outer peripheral surface of the plug-in end of the socket housing is provided with housing external threads. The plug includes a plug pin part 3 whose front end is a plug-in end. The plug pin part includes a pin holder 10 on which a plug pin 11 is installed. The connecting nut 2 is rigidly docked with the socket pin 15 of the socket pin part, and the inner side of the connecting nut is sheathed on the pin holding body with a sealing ring 9 for sealingly cooperating with the plug-in end of the socket housing. The pin holding body is provided with a body external thread on the rear outer peripheral surface of the connecting nut, and the body external thread is screwed with a fastening nut 7 for fixing the corresponding tail sheath 13 to the rear end of the pin h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com