An Automatic Control Method of Chlorinator Opening Based on Analog Feedback

An analog quantity and controller technology, applied in the field of automatic control of chlorinator opening based on analog quantity feedback, can solve the problem of being unable to know how long the chlorinator has been on or off, and it is difficult to know exactly what is on or off The degree and information cannot be fed back to the computer, etc., to achieve the effect of being conducive to market promotion, strong practical application significance, and simple and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

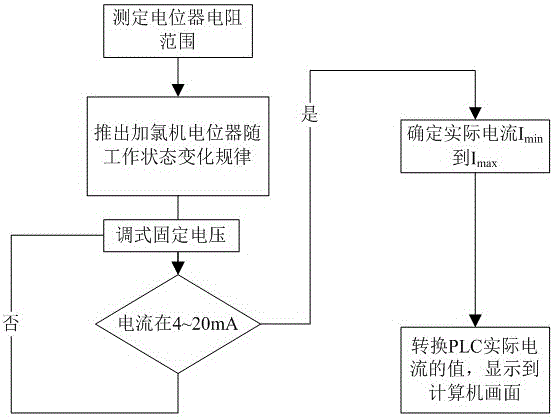

[0023] Such as figure 2 As shown, first connect the voltage generated by the fixed power supply to the potentiometer of the chlorinator in series, and then connect the current generated by this circuit to the analog module of the programmable logic controller PLC, and then combine the programmable logic controller PLC programming software, Display the current conversion value of the corresponding port on the computer screen through the configuration software INTOUCH.

[0024] A method for automatically controlling the opening of a chlorinator based on analog feedback, comprising the following steps:

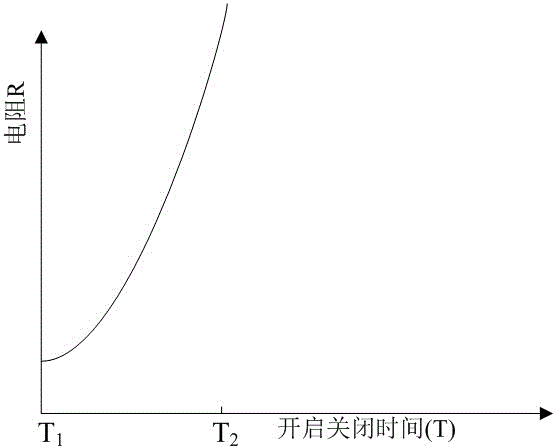

[0025] 1) Establish the functional relationship between the potentiometer resistance R and the working state of the chlorinator (completely closed to fully open)

[0026] The voltage U1 generated by the fixed power supply is connected in series with the potentiometer of the chlorinator to form a circuit loop, and an ammeter is connected to the circuit loop to detect the current...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com